IO-390-D Series Engine Maintenance Manual

© 2020 Avco Corporation. All Rights Reserved

72-20

March 2020

Page 163

IO-390-D Series Engine Maintenance Manual

E.

Connecting Rod Installation

NOTICE:

Each connecting rod is identified by a letter (A, E, S, etc.) as a designation for

weight class. All of the connecting rods installed on the crankshaft must be of the

same weight class.

(1)

Ensure that all of the connecting rods have the same weight class letter.

(2)

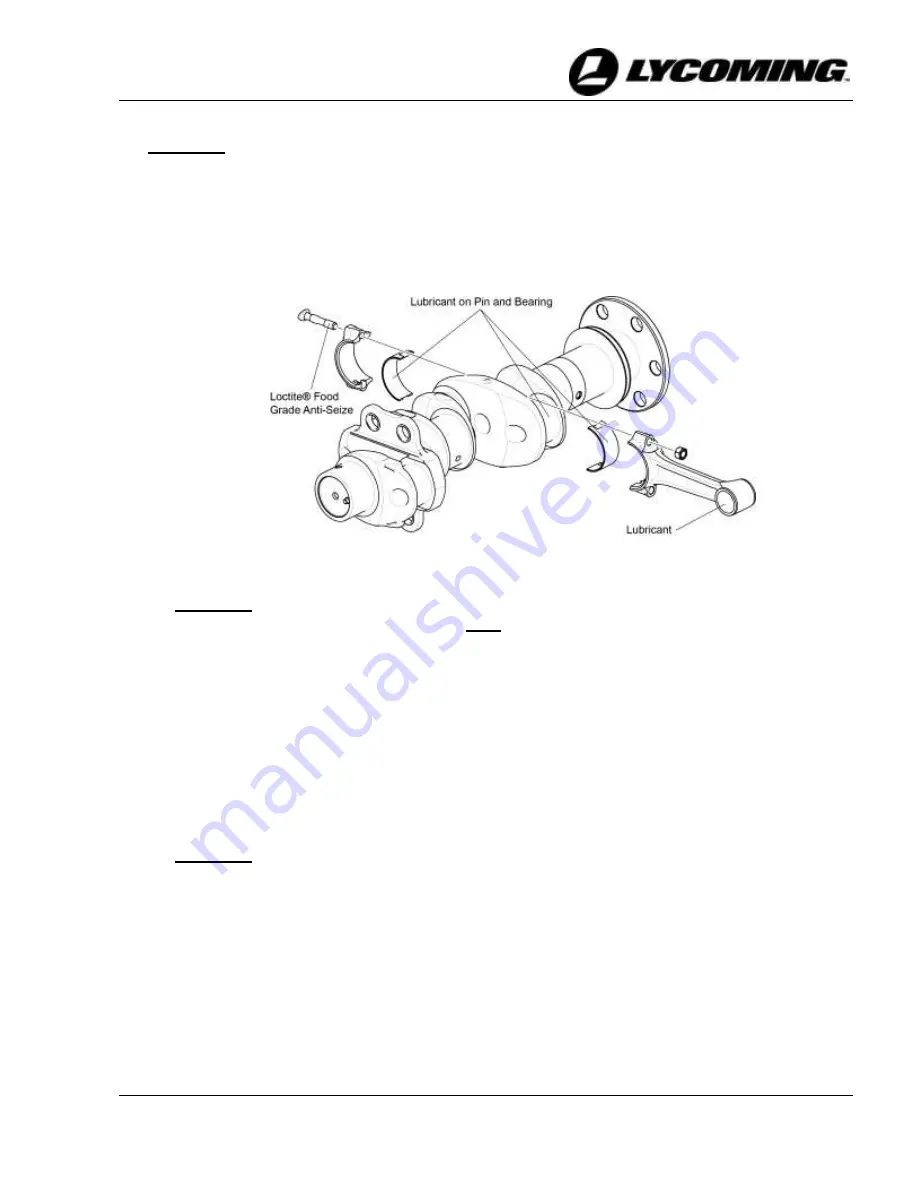

Apply specified lubricant to the connecting rod bearings (per the latest revision of Service

Instruction No. SI-1059) in Figure 50. Different lubricants are used on the connecting rod

bearings.

Figure 50

Connecting Rod Assembly Lubrication

NOTICE:

Anytime either the connecting rod bolt and/or nut pairs are removed from a

Lycoming engine, replace

both

the bolt and nut pairs with new “Service Use

Only” hardware regardless of apparent condition.

(3)

Refer to the latest revision of Service Instruction No. SI-1458 to identify the correct P/Ns

for the new connecting rods bolts.

(4)

Make sure the new connecting rod bolt and new nut pairs are clean, free of dirt and debris

and that the threads are not damaged.

(5)

Install the new lubricated matched set bearing insert pair on each connecting rod, one

bearing insert on the connecting rod and the other bearing insert on the connecting rod

cap. Ensure that the tang of each bearing insert fits and seats within the slot of either the

connecting rod as well as the connecting rod cap.

NOTICE:

Do not install standardized connecting rod bolts in connecting rods with oversize

bolt holes. Refer to the latest revision of Service Instruction No. SI-1458 for

details.

(6)

Apply Loctite

®

Food-Grade Anti-Seize Lubricant or equivalent to the bottom two or three

threads of the new connecting rod bolts (Figure 50). Wipe away excess lubricant with a

clean, lint-free cloth.

(7)

Apply engine oil mixture to the crankpin journals.

(8)

Install each connecting rod pair (with the bearing inserts installed) on their respective

crank pins on the crankshaft (where the numbers on the connecting rods and bearing

locks point down - toward the oil sump.)