IO-390-D Series Engine Maintenance Manual

72-20

© 2020 Avco Corporation. All Rights Reserved

Page 144

March 2020

IO-390-D Series Engine Maintenance Manual

Crankshaft Inspection Checklist for IO-390-D Series Engines (Cont.)

Item

Comments

Findings/

Corrective Action

Done

Crankshaft Gear Inspection (Cont.)

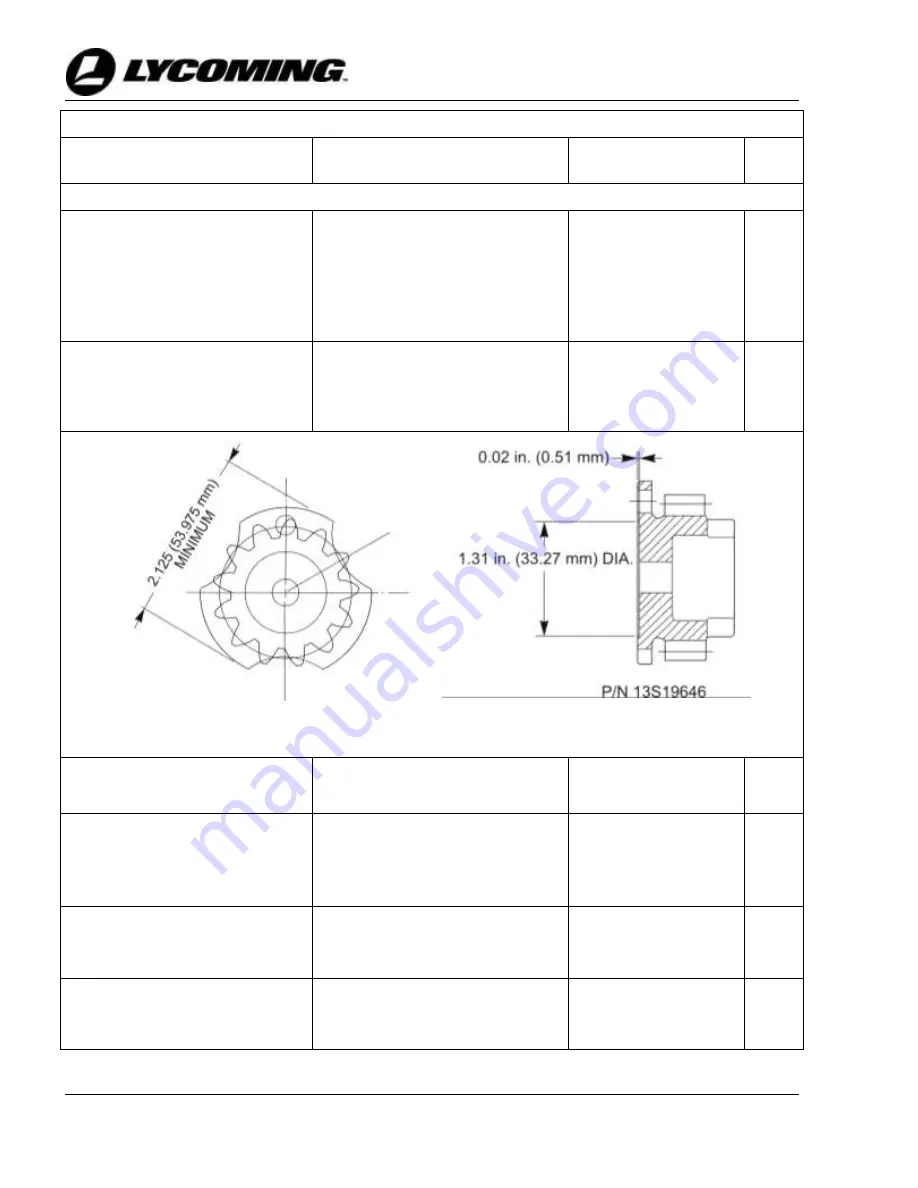

Measure the diameter of the

pilot flange of the crankshaft

gear (Figure 29).

If the diameter of the pilot flange

is less than 2.125 in. (53.975

mm) do not install this gear on

the crankshaft. Replace the

crankshaft gear with a

serviceable crankshaft gear.

Measure dimensions on the

crankshaft gear per those shown

in Figure 29 for the respective

crankshaft gear part number.

Acceptable

Replace

Figure 29

Details for Crankshaft Gears to Current Configuration

Examine the crankshaft gear for

pitting and wear.

Replace a pitted or worn

crankshaft gear.

Acceptable

Replace

Examine the pilot flange

diameter of the crankshaft gear

for damage from galling or

fretting.

If the pilot flange of the

crankshaft gear is damaged,

replace the crankshaft gear.

Acceptable

Replace

If there is a hole or slot on the

crankshaft gear, examine the

slot for any nicks or dents.

If nicks or dents are found,

replace the crankshaft gear.

Acceptable

Replace

Complete a magnetic particle

inspection of the crankshaft

gear.

Refer to the “Non-Destructive

Testing” section in Chapter 05-

50.

Acceptable

Replace