IO-390-D Series Engine Maintenance Manual

© 2020 Avco Corporation. All Rights Reserved

72-20

March 2020

Page 167

IO-390-D Series Engine Maintenance Manual

17.

Oil Plug Installation (if removed)

A.

Make sure the 1/8 NPT oil plugs are acceptable, not damaged or cracked. Replace any worn,

damaged or cracked NPT plug.

B.

Apply of coating of Loctite

®

564 or equivalent to all six of the 1/8 NPT oil plugs.

C.

Install three of 1/8 NPT oil plugs in each crankcase half (Figure 61 A, B, and C).

D.

Torque each 1/8 NPT oil plug to 40 in.lb. (4.5 Nm).

Figure A

Figure B

Figure C

Figure 61 A, B and C

Oil Plug Installation Steps

18.

Tappet Assembly Installation

NOTICE:

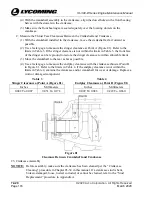

Roller tappets (Figures 62 and 63) are installed in the crankcase halves on Lycoming

IO-390-D Series engine models.

Roller tappets are not field repairable and are not to be disassembled for parts re-use.

Roller tappets only can be replaced and are to be replaced during overhaul.

Figure 62

Roller Tappet

Figure 63

Installed Roller Tappets

A.

Plunger Assembly Installation

CAUTION

DO NOT MIX PLUNGER OR LIFTER ASSEMBLIES WITH DIFFERENT

PART NUMBERS IN THE SAME ENGINE. THE DIFFERENT LEAK

DOWN RATES WILL CAUSE INCORRECT ENGINE OPERATION.

ALL PARTS OF EACH HYDRAULIC PLUNGER ASSEMBLY ARE

SELECTIVELY FITTED AND ARE NOT INTERCHANGEABLE.

MATING PARTS MUST BE KEPT TOGETHER. IF THERE IS ANY

DOUBT AS TO WHETHER THE PARTS HAVE BECOME MIXED,

INSTALL NEW PLUNGER ASSEMBLIES.