IO-390-D Series Engine Maintenance Manual

© 2020 Avco Corporation. All Rights Reserved

72-70

March 2020

Page 245

IO-390-D Series Engine Maintenance Manual

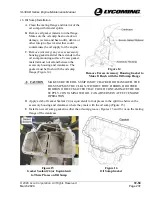

(c)

Quickly release the handle of the Belt

Tension Dial Gage (ST-131) and read the

indicated belt tension on the dial (Figure 3).

(d)

Repeat the previous steps several times to

ensure an accurate reading.

(e)

If the tension reading on the alternator belt

is out of tolerance, adjust the belt tension

per the “Alternator Belt Tension

Adjustment” procedure for the respective

alternator in this chapter to get the

appropriate reading on the Belt Tension Dial

Gage (ST-131).

Figure 3

Indicator on the

Belt Tension Dial Gage (ST-131)

C.

Alternator Belt Tension Adjustment

(1)

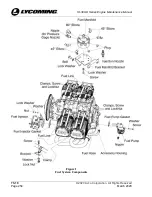

Cut and remove the safety wire from the alternator adjusting link where shown in Figure

4.

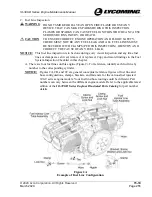

(2)

Loosen the bolt that attaches the alternator adjusting link to the alternator (Figure 5).

(3)

Loosen the bolt that attaches the alternator adjusting link to the crankcase.

(4)

Rotate the alternator on the bracket to adjust the alternator belt tension.

(5)

Torque the two bolts on the alternator adjusting link to 17 ft.-lb. (23 Nm).

(6)

Torque the idler pulley nut to 75 ft.-lb. (101 Nm).

(7)

Complete the “Alternator Belt Tension Check/Adjustment” procedure per the applicable

method in this chapter.

(8)

Install new safety wire on the cotter pins and two bolts on the alternator adjusting link as

shown in Figure 4.

Figure 4

Safety Wire on Bolts of

Alternator Adjusting Link

Figure 5

Alternator and Alternator Bracket