IO-390-D Series Engine Maintenance Manual

12-30

© 2020 Avco Corporation. All Rights Reserved

Page 94

March 2020

IO-390-D Series Engine Maintenance Manual

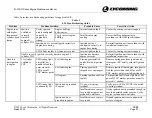

Table 1 (Cont.)

Fault Isolation Guide

Problem

Cause

Corrective Action

Ref.

Excessive oil

consumption

(Cont.)

Worn valve guides

1.

Measure the valve guides for wear

as per instructions in the section

“Exhaust Valve and Guide

Inspection.”

2.

Replace worn valve guides.

72-30

Oil leaks

Examine the external area of the

engine for leaks, identify and correct

the cause of any leak.

Oil siphoned from

engine during flight

1.

Verify that the oil filler cap is

secure and has either safety wire or

cable, and the oil access door

closes correctly.

2.

Make sure that the breather tube is

accurately cut and the crankcase

ventilation system is installed

correctly per the airframe

manufacturer’s instructions.

12-10

Oil level too high

Do not fill above the maximum oil

sump capacity.

IOM

Appendix A

Drain some oil (start of “Oil Change

Procedure.”)

12-10

High oil

temperature

Cooling baffles are

missing, broken, or

incorrectly installed

Ensure that all baffles are installed

correctly and none are broken.

Replace as necessary.

NOTICE:

Never modify, relocate, or

eliminate any cooling baffles.

Oil level is too low

Complete the “Oil Level Check” at

regular intervals. Keep oil at the

specified level.

12-10

Incorrect grade of oil

Use the correct grade of oil per the

latest revision of Service Instruction

No. SI-1014..