IO-390-D Series Engine Maintenance Manual

© 2020 Avco Corporation. All Rights Reserved

12-30

March 2020

Page 95

IO-390-D Series Engine Maintenance Manual

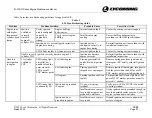

Table 1 (Cont.)

Fault Isolation Guide

Problem

Cause

Corrective Action

Ref.

High oil

temperature (Cont.)

Oil cooler bypass valve

is not operating

correctly or seating

accurately

Replace the oil cooler bypass valve.

72-50

SI-1316

Leaks in engine

induction system

Identify and correct the cause of all

leaks.

72-80

&

AMM

Oil cooler or oil cooler

lines are fully or

partially blocked

1.

Remove the oil cooler and oil

cooler lines.

2.

Clean and service the oil cooler.

AMM

Too much cylinder

blow-by

Complete a “Cylinder Compression

Check Procedure.”

72-30

Defective oil

temperature gage

1.

Install the master temperature

gage and operate the engine to

compare gages.

2.

Replace the faulty gage if

necessary.

AMM

Higher than normal

cylinder head

temperatures

Incorrect EIS-to-engine

timing

Refer to the “EIS Troubleshooting

Guide” in this chapter.

High manifold

pressure at idle

Air leak in induction

system

Examine the induction system for

leaks. Identify and correct the cause of

all leaks.

NOTICE:

If the induction system

has leaks, the engine will idle rough.

72-80

&

AMM

Incorrect tappets or

hydraulic lifters were

installed

Replace hydraulic lifters with the

correct part number for lifters. Refer

to the latest revision of Service

Instruction Nos. 1529, 1011, and

1514.

NOTICE:

Keep the cylinders and

plungers together as an assembly

when you remove hydraulic lifters

from the engine. If they become

separated, replace with new ones.

Incorrectly assembled body and

plunger assemblies will change the

leak-down rate.

72-20