IO-390-D Series Engine Maintenance Manual

72-50

© 2020 Avco Corporation. All Rights Reserved

Page 238

March 2020

IO-390-D Series Engine Maintenance Manual

F.

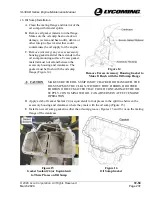

Align the oil sump flange with the bottom of the mated crankcase halves as shown in Figure

17.

Figure 17

Oil Sump Aligned with Crankcase

CAUTION

ALL OF THE OIL SUMP FASTENERS (STUDS, BOLTS, AND NUTS)

MUST BE INTACT TO ENSURE CORRECT AND SECURE

TIGHTENING TO PREVENT OIL LEAKAGE AT THE OIL SUMP

MATING FLANGE WITH THE CRANKCASE. NO OIL IS TO LEAK

OUT OF THE OIL SUMP.

G.

Examine all of the oil sump fasteners identified as A, B, and C in Figure 13, that were to be

kept separate when the oil sump was removed. Make sure the bolts, studs, and nuts are not

damaged are intact and have no stripped threads. Replace any damaged or stripped fastener.

H.

Install the two “C” bolts each with a nut, two washers, and a new lock washer, at the location

shown in Figure 13, finger-tight.

I.

Install the 10 “B” bolts, each with a nut, two washers and new lock washer finger-tight.

J.

Install the eight “A” bolts each with a washer and new lock washer finger-tight.

K.

Torque all of the bolts on the oil sump to 96 in.-lb. (11 Nm).

CAUTION

TO PREVENT OIL LEAKAGE, MAKE SURE THAT THE OIL DRAIN

PLUG IS INSTALLED TIGHTLY IN THE OIL SUMP. SAFETY THE OIL

DRAIN PLUG.

L.

Install the oil drain plug in the threaded hole of the oil sump. Torque the oil drain plug per the

torque value in the latest revision of the

Service Table of Limits - SSP-1776

.

M.

Safety wire/cable the oil drain plug in accordance with the best standard practices per the

latest revision of AC43.13-B or the latest revision of Service Instruction No. SI-1566.

N.

Install the intake pipes per Chapter 72-80

O.

After maintenance is completed, add the correct oil to the engine per instructions in Chapter

12-10.