IO-390-D Series Engine Maintenance Manual

© 2020 Avco Corporation. All Rights Reserved

12-10

March 2020

Page 79

IO-390-D Series Engine Maintenance Manual

Table 3 (Continued)

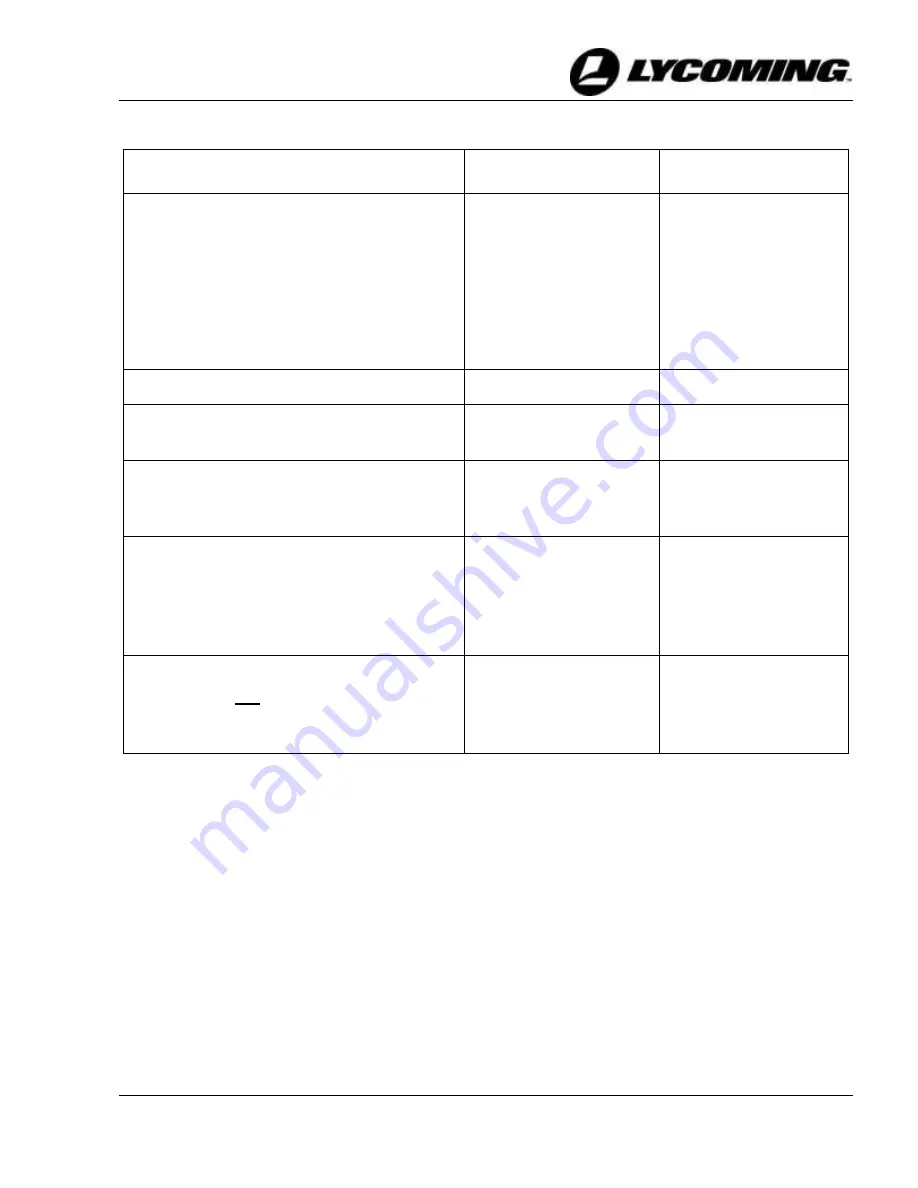

Guidelines for Particle Quantity and Size on Oil or Oil Suction Screen

Condition

Source of Particles

Corrective Action

(Table 4)

Chunks (3/16-inch or larger) in oil suction

screen

Valve

Tappet

Ring

Piston

Bearing

Machining chips

Corrective Action 3

and contact Lycoming

Product Support

Bronze chips in the oil suction screen

Connecting rod bushing

Corrective Action 6

More than five bronze chips found in the oil

filter or oil suction screen

Connecting rod bushing

Corrective Action 6

More than three bronze chips AND more

than three aluminum chips found in the oil

filter or oil suction screen

Connecting rod bushing

and piston

Corrective Action 7

1/4 teaspoon or more of metallic particles

and metal has gotten past the oil filter

Cylinders

Bearings

Piston

Piston pin plugs

Corrective Action 4

1/4 teaspoon or more of metallic particles

and metal has

not

gotten past the oil filter

Possibly only one

engine cylinder is

damaged or spark plug

is worn or damaged

Corrective Action 5

If the cause of the metal contamination cannot be identified, speak with the Lycoming Engines

Technical Support, phone number at the front of this manual.

If there is unusual aluminum, bronze, or iron contamination in the oil, make sure you have a full

description of the engine model, serial number, history, oil temperatures, oil pressure, unusual

performance, and properties of the metal contamination (color, size, metallic/nonmetallic, shape,

etc.). This information will help Technical Support identify the cause of the contamination.

Coordinate with an appropriate oil analysis laboratory to have the material analyzed. For factory

new, factory rebuilt or factory overhauled Lycoming engines within their hourly or 12-year required

TBO cycle, if, contact Lycoming Engines Technical Support prior to sending the oil filter element

and metallic material to Lycoming Engines for analyses.

A change in the usual wear rate of a part is not necessarily an indication of imminent failure. It is an

indication that a cylinder borescope inspection, cylinder compression pressure check, etc. are

necessary to identify the cause for unusual wear.