IO-390-D Series Engine Maintenance Manual

© 2020 Avco Corporation. All Rights Reserved

73-10

March 2020

Page 263

IO-390-D Series Engine Maintenance Manual

(5)

Torque each fuel line fitting in accordance with the Standard Torque Tables in the latest

revision of the

Service Table of Limits - SSP-1776

.

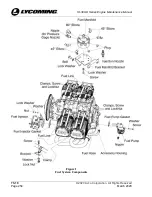

Figure 6

Fuel Injector Lines

(6)

Make sure that the fuel lines are securely held in place, attached to the engine (to dampen

vibration during flight) with the necessary serviceable cushioned clamps and hardware.

Install clamps on the fuel line as per the following guidelines:

(a)

Make sure each serviceable clamp securely supports the fuel line to prevent fuel line

movement due to vibration, friction, or motion frequencies during flight.

Do NOT

use plastic tie straps as clamps.

(b)

Install serviceable clamps (preferably with cushions) on the fuel line. Make sure the

cushion is not missing and is intact, and completely covers the fuel line diameter. If

cushions are deteriorated or missing, replace the clamp with a new clamp with the

cushion intact.

(c)

Refer to Figures 4 and 5 which show how the fasteners are to be installed on P-clamps

and L-shaped clamps.

(d)

Make sure the clamps are securely attached to support the fuel line and to prevent

movement from vibration or motion frequencies.

(e)

On engines that used metal clamps with no cushion, use the P/N LW-12598 fuel line

sleeve at each of those clamping locations. (Do not use the fuel line sleeve with the

serviceable cushioned clamps.)

(f)

Torque the fuel line union nut (Figure 7) between 35 to 50 in.-lb. (4 to 6 Nm).