IO-390-D Series Engine Maintenance Manual

73-10

© 2020 Avco Corporation. All Rights Reserved

Page 266

March 2020

IO-390-D Series Engine Maintenance Manual

A.

Injection Nozzle Removal

(1)

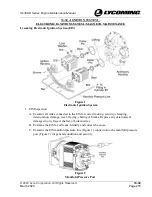

Disconnect the fuel line from the injection nozzle (Figure 10).

(2)

Remove the injection nozzle from the engine cylinder.

Figure 10

Injection Nozzle

B.

Injection Nozzle Cleaning

CAUTION

NEVER USE A SHARP TOOL SUCH AS A WIRE OR PIN TO CLEAN

OUT AN INJECTION NOZZLE. DAMAGE TO THE INLET AND

OUTLET FUEL RESTRICTORS COULD OCCUR WHICH WOULD

CHANGE THE FUEL FLOW.

Complete the “Injection Nozzle Cleaning” procedure in Chapter 5-30.

NOTICE

: Injection nozzles are not repairable.

C.

Injection Nozzle Installation

(1)

(Optional) Complete the “Injection Nozzle Fuel Flow Check” in this chapter.

(2)

Lightly lubricate the injection nozzle threads with engine oil mixture.

(3)

Install the injection nozzle (Figure 10) on the engine cylinder.

(4)

Torque the injection nozzle to 60 in.-lb. (7 Nm). Continue to torque the injection nozzle

until the letter or number stamped on the nozzle points downward.

(5)

Connect the fuel line to the injection nozzle.

(6)

During the “Operational Ground Check” in Chapter 72-00 (which is to be done after all

maintenance is complete), look for fuel leaks at the fuel lines and connections during

engine operation. Identify and correct the cause of any fuel leak. There must not be any

fuel leaks when the engine is returned to service.