IO-390-D Series Engine Maintenance Manual

73-10

© 2020 Avco Corporation. All Rights Reserved

Page 258

March 2020

IO-390-D Series Engine Maintenance Manual

CAUTION

DO NOT RETURN THE ENGINE TO SERVICE UNLESS THE ENGINE

IS OPERATING CORRECTLY AND DOES NOT HAVE ANY LEAKS.

THERE MUST NOT BE ANY FUEL LEAKS. A FUEL LEAK CAN

CAUSE A FIRE.

E.

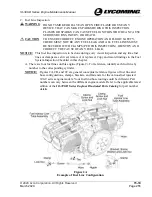

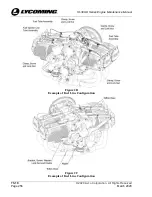

Make sure no fuel lines touch the engine or aircraft baffle hardware. There must be a

minimum clearance of 3/16 in. (4.76 mm) between a fuel line and any engine or aircraft

surface.

F.

After the inspection, refer to Table 1 for any corrective action if necessary.

Table 1

Corrective Action for Fuel Lines

Condition

Corrective Action

Leaky, cracked, brittle, worn, chafed, fuel line

Bent (non-kinked) stainless steel fuel lines that

have an inside radius less than 5/8 in. (15.88

mm)

Do NOT repair any fuel line that leaks or is

cracked, brittle, worn, or chafed.

Replace the fuel line with a new fuel line.*

Damaged, pitted, nicked, dented, loose, crimped

or kinked fuel line or fuel line with sharp bends

greater than that shown in Figure 3

Do NOT re-use any fuel line that is damaged,

dented, pitted, crimped, or kinked. Dents can

cause cracks to form.

Replace the fuel line with a new fuel line.*

No clamps installed on fuel line that had been in

service

Replace the fuel line with a new fuel line and

install serviceable cushioned clamps on the fuel

line to securely hold the fuel line in place and

prevent fuel line movement from vibration.*

Loose clamps

Replace the fuel line with a new fuel line and

install serviceable cushioned clamps on the fuel

line to securely hold the fuel line in place and

prevent fuel line movement from vibration.*

Deteriorated cushion on clamp, missing

cushion, or cushion does not completely cover

the fuel line diameter. (On engines that used

metal clamps with no cushion, use the P/N LW-

12598 fuel line sleeve at each of those clamping

locations. The fuel line sleeve is not used with

the cushioned clamps.)

Examine fuel lines in areas adjacent to the

clamp. Replace any fuel line that has any

conditions identified above.*

Replace the clamp with a new serviceable

cushioned clamp.

Problem with fuel injector clamp installation

caused by obstructive baffling

Install the fuel injector clamps to enable

clearance.

* Refer to the “Fuel Line Replacement” procedure in this chapter.