IO-390-D Series Engine Maintenance Manual

12-30

© 2020 Avco Corporation. All Rights Reserved

Page 92

March 2020

IO-390-D Series Engine Maintenance Manual

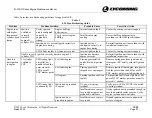

Table 1 (Cont.)

Fault Isolation Guide

Problem

Cause

Corrective Action

Ref.

Low oil pressure

(Cont.)

Pressure relief valve is

out of adjustment

Turn the adjusting screw (on the oil

pressure relief valve) to adjust oil

pressure or change the spring as

necessary

72-50

Dirt or metal chips

under the oil pressure

relief valve

1.

Remove, disassemble, and clean

(remove dirt or metal chips) the oil

pressure relief valve.

2.

Complete the “Oil Change

Procedure.”

3.

Complete a cylinder compression

check.

72-50

12-10

72-30

Blockage at inlet side of

oil pump

Remove and clean the oil suction

screen and oil passage on the inlet side

of the oil pump. Refer to the section

"Oil Suction Screen Removal/

Inspection/Cleaning/

Installation.”

12-10

Damaged oil pressure

relief valve seat

Replace the oil pressure relief valve

seat per the latest revision of Service

Instruction No. SI-1172.

Excess internal oil

leakage

Look for:

•

Loose or missing plugs in oil galley

•

Piston cooling nozzles to lock open

during idle rpm

•

Too much bearing clearance

•

Cracks in the oil galley area of the

crankcase

Air leak on suction side

1.

Examine the conditions of these

components:

•

Oil suction screen gasket

12-10

•

Oil sump gasket

72-50

•

Oil pump mating surface to

accessory housing

2.

Replace cracked or damaged parts.

72-25

Relocated oil pressure

take-off

Use only the approved oil pressure

take-off point.