IO-390-D Series Engine Maintenance Manual

05-50

© 2020 Avco Corporation. All Rights Reserved

Page 58

March 2020

IO-390-D Series Engine Maintenance Manual

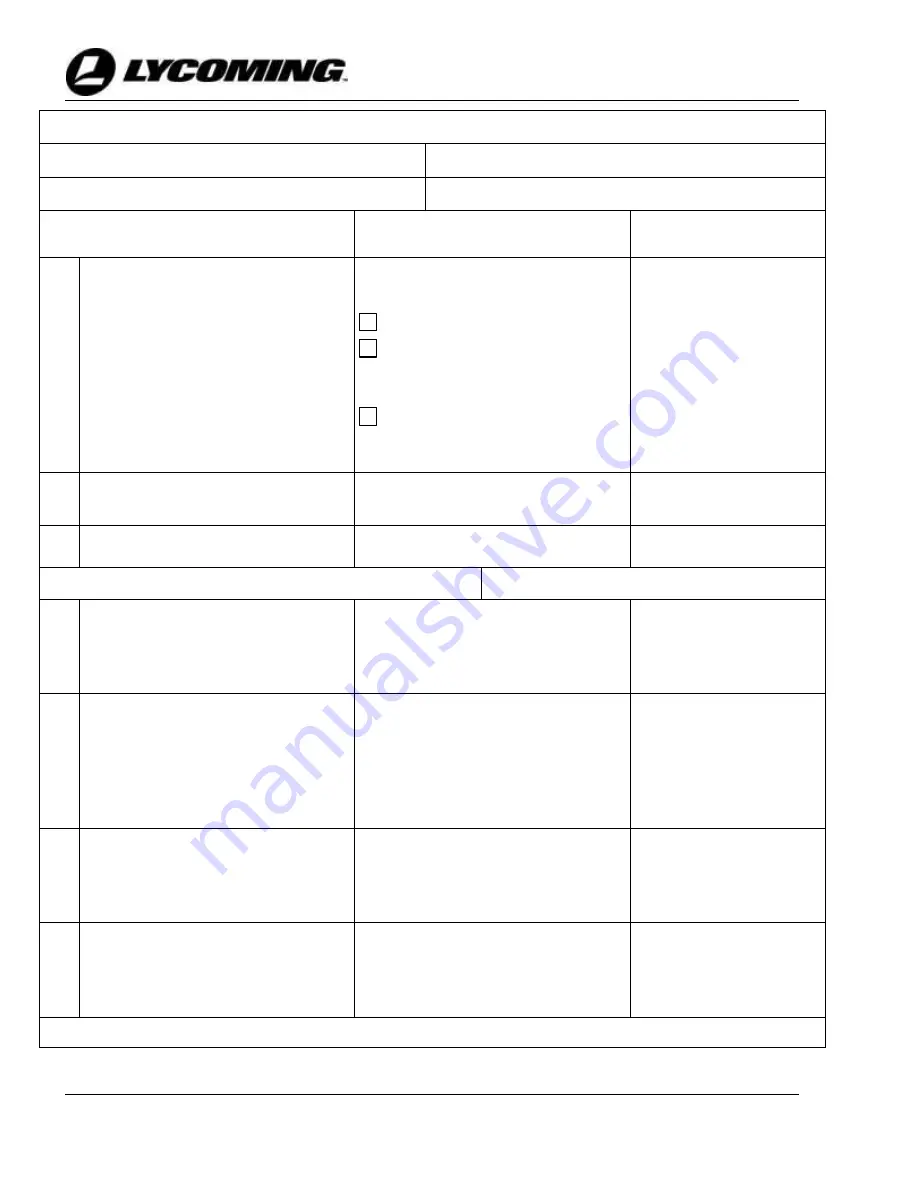

Engine Inspection Checklist After Propeller Strike for IO-390-D Series Engines

Engine Model Number:

Engine Serial Number:

Date Inspection Started:

Date Inspection Completed:

Sequential Task

Additional Information

Corrective Action

Done/Comments

1.

Examine the propeller for extent of

damage; record condition of

propeller.

Condition of Propeller/Corrective

Action:

Propeller satisfactory

Repair propeller in accordance

with propeller manufacturer's

instructions

Replace propeller in accordance

with the airframe manufacturer's

instructions.

2.

Remove the propeller.

As per airframe and propeller

manufacturer’s instructions.

3.

Remove the engine.

Refer to Chapter 72-00

CRANKCASE P/N:

MATCH NO:

4.

Disassemble the engine - remove

the crankshaft, camshaft,

connecting rods, crankshaft gear,

and internal steel parts.

Refer to Table 1 - Sequence of

Engine Disassembly in Chapter 72-

05

5.

Complete grit-blast cleaning* of

the crankcase with fine abrasive

(150-grit or finer) remove all

coatings on the crankcase and

engine mount bosses.

Make sure there is no dirt, debris,

sludge, paint, or any other

substance that could prevent

reliable Fluorescent Penetrant

Inspection (FPI) or subsequent oil

flow.

6.

Complete grit-blast cleaning* of

the oil sump and engine mount

bosses with fine abrasive (150-grit

or finer).

Make sure there is no dirt, debris,

sludge, paint, or any other substance

that could prevent reliable FPI or

subsequent oil flow.

7.

Complete grit-blast cleaning* of

the engine mount brackets (if used)

with fine abrasive (150-grit or

finer).

Make sure there is no dirt, debris,

sludge, paint, or any other

substance that could prevent

reliable FPI or subsequent oil flow.

* Refer to the “Grit-Blast Procedure” in Chapter 05-30.