IO-390-D Series Engine Maintenance Manual

72-80

© 2020 Avco Corporation. All Rights Reserved

Page 252

March 2020

IO-390-D Series Engine Maintenance Manual

B.

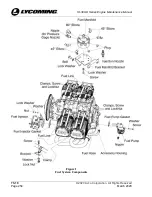

Intake Pipe Installation

NOTICE:

Since there is a corresponding intake pipe for each engine cylinder, make sure the

intake pipe of the correct part number is installed for the respective engine cylinder.

(1)

Apply a coating of clean engine oil to a new ring seal.

(2)

Install a new ring seal in the groove in the oil sump (Figure 1).

(3)

Push the intake pipe into the oil sump until it seats.

(4)

Attach the corresponding intake pipe centered on the correct engine cylinder flange with

a new gasket, two bolts, two new lock washers, and two washers. Torque the two bolts to

96 to 108 in.-lb. (11 to 12 Nm).

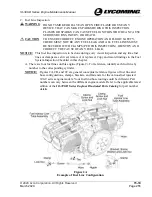

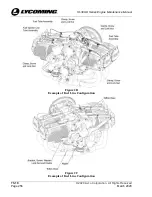

3.

Fuel Drain Valve Adapter Assembly Inspection

The fuel drain valve adapter assembly (Figure 2) is a valve in the induction system that closes

during engine operation and opens when the engine is shut down to allow excess fuel to drain

from the induction system. If the valve is not operating correctly it can either allow outside air

into the induction system during engine operation or fail to drain excess fuel from the induction

system when the engine is shut down.

If your engine has a fuel drain valve adapter assembly installed, examine the assembly as

follows:

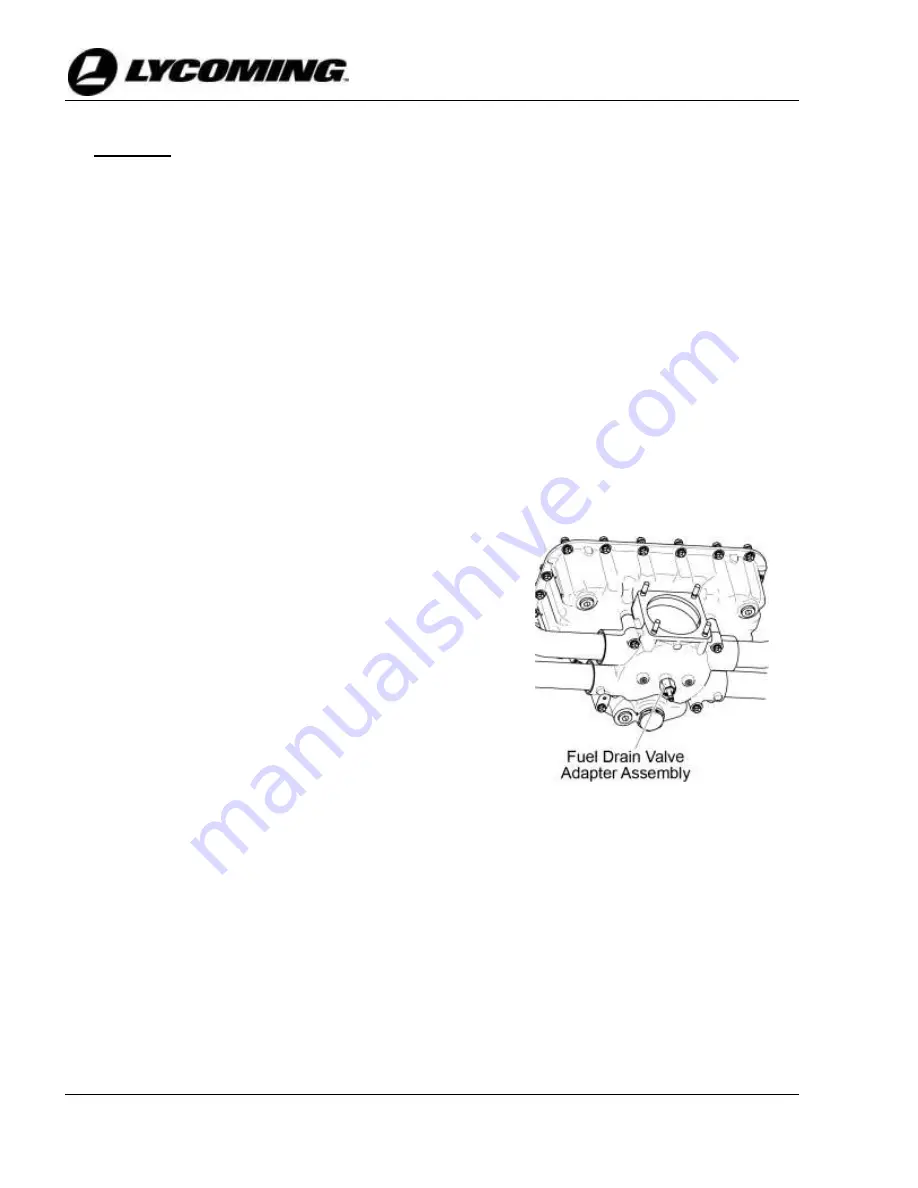

A.

Remove the fuel drain valve adapter assembly

from the induction system.

B.

Examine the fuel drain valve adapter assembly for

damage.

C.

Make sure the fuel drain valve adapter assembly is

operating correctly:

(1)

The valve is operating correctly if it is open

with no air pressure applied.

(2)

The valve is operating correctly if it closes

when 0.75 to 1.0 psi (5.2 to 6.9 kPa) of air

pressure is applied to the outboard side of the

fuel drain valve adapter assembly.

D.

If the valve is not operating correctly or if the fuel

drain valve adapter assembly is damaged, replace

the fuel drain valve adapter assembly.

E.

Apply a coating of Loctite

®

564 thread sealant or

equivalent to the threads of a serviceable fuel drain

valve adapter assembly.

F.

Install the fuel drain valve adapter assembly in the

oil sump. Torque the assembly to 40 in.-lb. (4.5

Nm).

Figure 2

Fuel Drain Valve Adapter Assembly