IO-390-D Series Engine Maintenance Manual

72-10

© 2020 Avco Corporation. All Rights Reserved

Page 122

March 2020

IO-390-D Series Engine Maintenance Manual

Engine Assembly Checklist

The Engine Assembly Checklist for IO-390-D Series Engines is a guide and a record of completion

for engine assembly.

Engine Assembly Checklist for IO-390-D Series Engines

Engine Model Number__________________ Engine Serial Number:__________________

Engine Time:______________________ Date of Engine Assembly: __________________

Engine Assembly done by:______________________________

Item

Comments

Done

Review the “General Assembly Practices” in this

chapter and the latest revision of Service Bulletin

No. SB-240 to identify all parts that must be

replaced with new parts upon removal..

Start with a clean crankshaft which passed the

“Crankshaft Inspection” in Chapter 72-20

Complete the “Alignment Dowel Inspection” and if

necessary, replace the alignment dowel per

instructions in Chapter 72-20.

CAUTION

FOR CORRECT ENGINE OPERATION, THE CRANKSHAFT GEAR

MUST BE INSTALLED CORRECTLY WITH NO GAP IN THE MATING

SURFACES BETWEEN COUNTERBORED-END OF THE

CRANKSHAFT AND THE CRANKSHAFT GEAR.

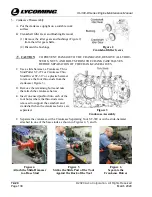

Complete the “Crankshaft Gear Installation” with a

new

crankshaft gear bolt and new lockplate Chapter

72-20.

Install a

new

expansion plug in the crankshaft per

the “Expansion Plug Installation” procedure in

Chapter 72-20.

Either begin installation of a

new

solid-ring oil seal

on the crankshaft per the “Solid-Ring Crankshaft

Oil Seal Installation” procedure in Chapter 72-20 or

later on install a split oil seal per the “Crankshaft

Oil Seal Installation” procedure in Chapter 72-20.

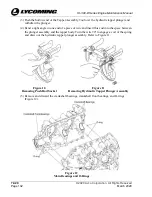

Complete the “Connecting Rod Inspection” in

Chapter 72-20.

Per the “Connecting Rod Installation“ section in

Chapter 72-20:

•

Measure the inside diameter of the bearing The

clearance is to be 0.004 to 0.016 in. (service) and

0.004 to 0.010 in. (on rebuilt engines). Compare

the results to the measurements previously

recorded.

•

Assemble and install the connecting rods (on the

crankshaft) each with a pair of new bearing

inserts, a new connecting rod bolt, and a new nut.

Measurement

#1

#2

#3

#4