3-

14

750/760 Feeder Management Relay

GE Power Management

3.2 TYPICAL WIRING

3 INSTALLATION

3

When the

BREAKER STATE BYPASS

setpoints are enabled, the trip and close coil supervision circuits can be

arranged to monitor the trip and close circuits continuously, unaffected by breaker state. This application

requires that an alternate path around the 52a or 52b contacts in series with the operating coils be provided,

with modifications to the standard wiring as shown on drawing 818730. With these connections, trickle current

can flow at all times. If access to the breaker coil is available, as shown in drawing A above, continuous coil

monitoring regardless of breaker state is possible without using a resistor to bypass the 52a/b contact.

3.2.12 SOLID STATE TRIP OUTPUT

A high speed solid state (SCR) output is also provided. This output is intended for applications where it is

required to key a communications channel.

3.2.13 LOGIC INPUTS

Ensure correct polarity on logic input connections and do not connect any logic input circuits

to ground or else relay hardware may be damaged.

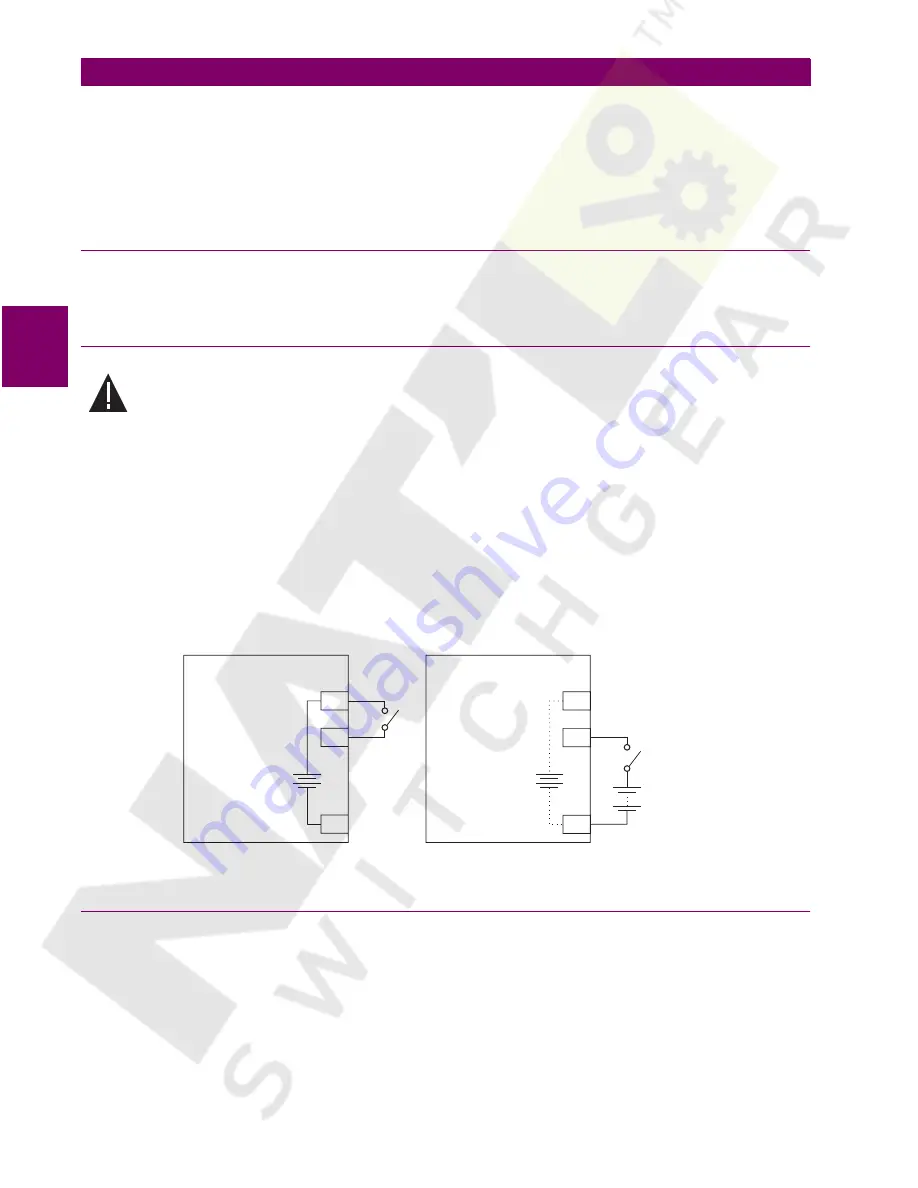

External contacts can be connected to the relay’s 14 logic inputs. As shown, these contacts can be either dry

or wet. It is also possible to use a combination of both contact types.

A dry contact has one side connected to terminal C12. This is the +32 VDC voltage rail. The other side of the

dry contact is connected to the required logic input terminal. When a dry contact closes, a current of approxi-

mately 2 mA will flow through the associated circuit.

A wet contact has one side connected to the positive terminal of an external DC power supply. The other side

of this contact is connected to the required logic input terminal. In addition, the negative side of the external

source must be connected to the relay’s DC NEGATIVE rail at terminal D12. The maximum external source

voltage for this arrangement is 300 V DC.

Figure 3–17: DRY AND WET CONTACT CONNECTIONS

3.2.14 ANALOG INPUT

Terminals A1 (+) and A2 (–) are provided for the input of a current signal from a wide variety of transducer out-

puts - refer to technical specifications for complete listing. This current signal can represent any external quan-

tity, such as transformer winding temperature, bus voltage, battery voltage, station service voltage, or

transformer tap position. Be sure to observe polarity markings for correct operation. Both terminals are

clamped to within 36 volts of ground with surge protection. As such, common mode voltages should not

exceed this limit. Shielded wire, with only one end of the shield grounded, is recommended to minimize noise

effects.

CAUTION

C12

C12

C1

C1

D12

D12

32 Vdc

32 Vdc

+32 VDC

+32 VDC

LOGIC INPUT 1

LOGIC INPUT 1

DC NEGATIVE

DC NEGATIVE

SR RELAY

SR RELAY

30-300 Vdc

Dry Contact Connection

Wet Contact Connection

LOGICIN.CDR

Содержание 750

Страница 2: ......

Страница 4: ......

Страница 124: ...8 14 750 760 Feeder Management Relay GE Power Management 8 12 INSTALLATION 8 S1 RELAY SETUP 8 ...

Страница 144: ...10 14 750 760 Feeder Management Relay GE Power Management 10 10 MISCELLANEOUS FUNCTIONS 10 S3 LOGIC INPUTS 10 ...

Страница 152: ...11 8 750 760 Feeder Management Relay GE Power Management 11 3 OUTPUT RELAYS 3 7 AUXILIARY 11 S4 OUTPUT RELAYS 11 ...

Страница 216: ...12 64 750 760 Feeder Management Relay GE Power Management 12 9 BREAKER FAILURE 12 S5 PROTECTION 12 ...

Страница 484: ...17 78 750 760 Feeder Management Relay GE Power Management 17 10 PLACING THE RELAY IN SERVICE 17 COMMISSIONING 17 ...

Страница 488: ...A 4 750 760 Feeder Management Relay GE Power Management A 1 FIGURES AND TABLES APPENDIXA A ...

Страница 490: ...B 2 750 760 Feeder Management Relay GE Power Management B 1 EU DECLARATION OF CONFORMITY APPENDIXB B ...

Страница 492: ...C 2 750 760 Feeder Management Relay GE Power Management C 1 WARRANTY INFORMATION APPENDIXC C ...

Страница 502: ...x 750 760 Feeder Management Relay GE Power Management INDEX ...

Страница 503: ...GE Power Management 750 760 Feeder Management Relay NOTES ...