GBC StreamWire

7/23/2020

Repairs/Adjustments

4-39

REP 2.26 Upper Transport Latch Replacement

PARTS LIST ON PL 5.4

Use this procedure to remove and install the latch on the Upper Bypass

Assembly.

Removal Procedure

WARNING

Do not perform repair activities with the power on or electrical power

supplied to the machine. Some machine components contain

dangerous electrical voltages that can result in electrical shock and

possible serious injury. See Section 0, page vi for other languages.

1. Switch power OFF to eWire.

2. Disconnect the Power Cord.

3. Do REP 1.1

4. While supporting the upper transport with your free hand, release

the latch by pressing down on the pivot arm. Raise the Upper

Bypass carefully, it will rise quickly without the weight of the cover.

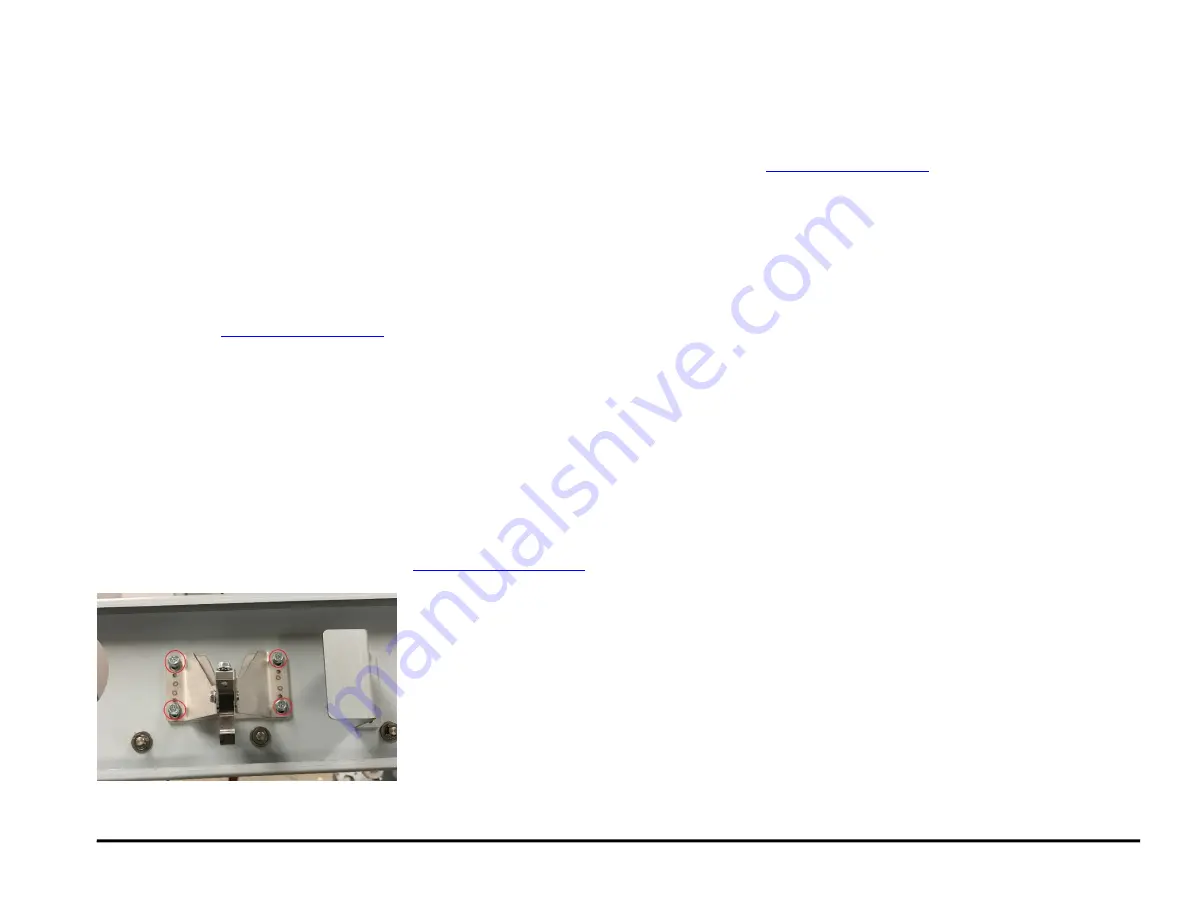

5. Remove the old Latch Assembly by removing the M4 Screws (4)

Installation Procedure

1. Place the new Latch onto the Upper Transport surface and secure it

using the M4 Screws (4).

2. Lower the Upper Bypass and gently seat the Upper Bypass by

pressing down on the Upper Bypass. If horizontal adjustment of the

Interlock Bracket is required, do REP 1.8

to remove the Front Cover.

3. Close the latch by lowering the Upper Bypass Assembly fully.

Ensure that the latch engages properly with the Catch. If necessary,

adjust the vertical position of the Catch by loosening the Screws on

the Catch Bracket and adjusting the position. A properly seated

cover will have around 1mm of movement.

5. Connect the Power Cord.

6. Power ON the eWire.

Summary of Contents for StreamWire

Page 9: ...GBC StreamWire 07 23 2020 Service Manual ix Notes...

Page 87: ...GBC StreamWire 07 23 2020 RTPS 2 72 Notes...

Page 89: ...Book Quality 07 23 2020 GBC StreamWire 3 2 This page intentionally left blank...

Page 428: ...GBC StreamWire 12 18 2018 Wiring Data 7 3 o System Wiring...

Page 429: ...Wiring Data 12 18 2018 GBC StreamWire 7 4 o Element Feeder Module...

Page 430: ...GBC StreamWire 12 18 2018 Wiring Data 7 5 o Element Transfer Module...

Page 431: ...Wiring Data 12 18 2018 GBC StreamWire 7 6 o Knife Module...

Page 432: ...GBC StreamWire 12 18 2018 Wiring Data 7 7 o Closer Module...

Page 433: ...Wiring Data 12 18 2018 GBC StreamWire 7 8 o Holder Module...

Page 434: ...GBC StreamWire 12 18 2018 Wiring Data 7 9 o Book Drawer...

Page 435: ...Wiring Data 12 18 2018 GBC StreamWire 7 10 o Paper Transport Module...

Page 436: ...GBC StreamWire 12 18 2018 Wiring Data 7 11 o Sheet Tappers Module...

Page 437: ...Wiring Data 12 18 2018 GBC StreamWire 7 12 o Deflector Module...

Page 438: ...GBC StreamWire 12 18 2018 Wiring Data 7 13 o Stacker Module...

Page 439: ...Wiring Data 12 18 2018 GBC StreamWire 7 14 o Alignment Module...

Page 440: ...GBC StreamWire 12 18 2018 Wiring Data 7 15 o Interlock AC and LCD Connections...

Page 442: ...Installation Instructions 03 26 2019 GBC StreamWire 8 2 This page intentionally left blank...