Appendix 3. Circular Cutting Radius Error

IV

-3

Appendix 3 Circular Cutting Radius Error

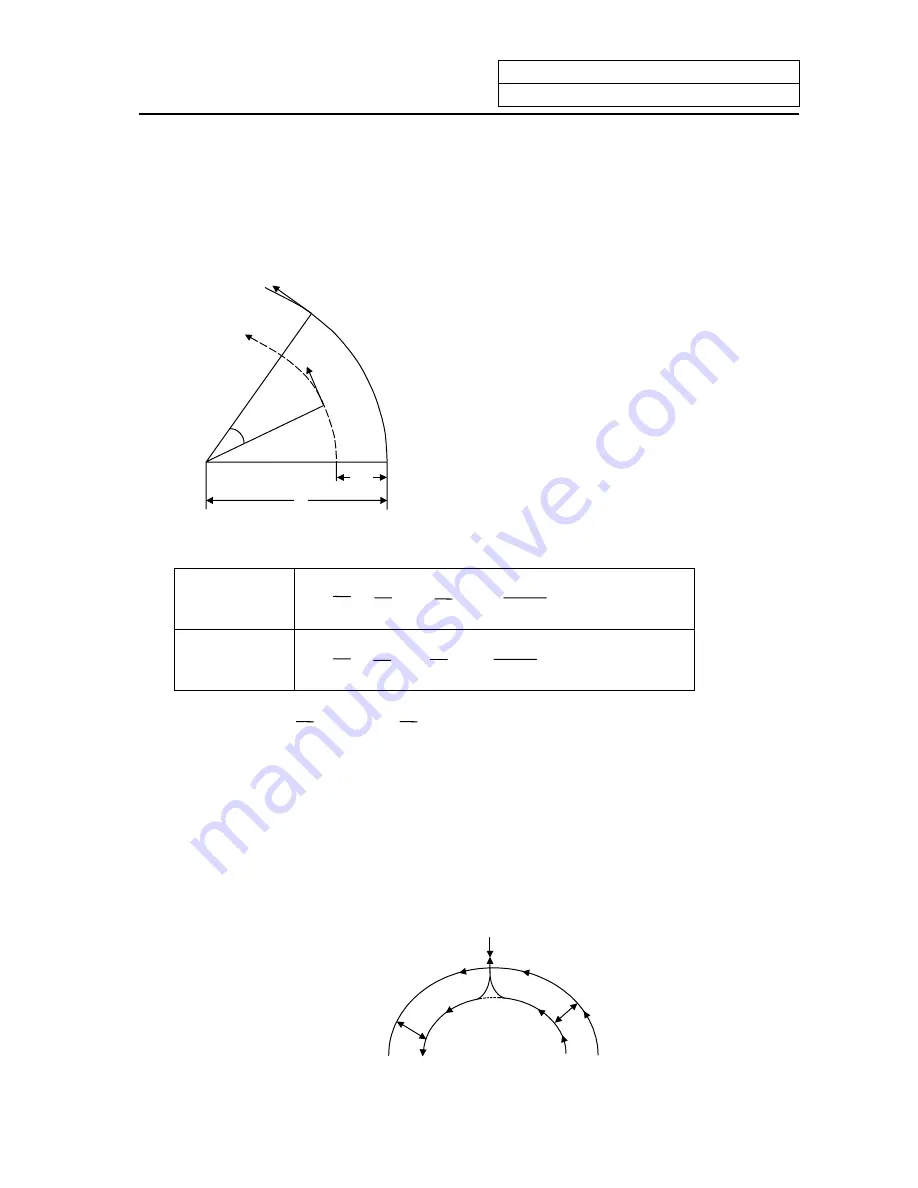

When circular cutting is performed, an error is caused between the command coordinate and the

tracking coordinate due to the tracking delay in the smoothing circuit and servo system, and the

workpiece ends up with a radius smaller than the commanded value. The method for obtaining this

error (radius error) is shown below.

A : Command coordinate

B : Tracking coordinate

R : Command radius (mm)

∆

R : Radius error (mm)

∆θ

: Angle error (rad)

F : Cutting feed rate (m/min)

A

F

B

∆θ

R

∆

R

F

The radius error

∆

R and angle error

∆θ

are calculated from the following formula.

Exponential

acceleration/

deceleration

∆

R = • ( Ts

2

+ Tp

2

) • ( )

2

(mm)

Linear

acceleration/

deceleration

∆

R = • ( Ts

2

+ Tp

2

) • ( )

2

(mm)

∆θ

= tan

–1

(Ts • ) + tan

–1

(Tp • ) (rad)

Ts: Time constant (s) of specified smoothing circuit

Tp: Position loop time constant

(Note

1)

When

the

∆

R radius error applying with circular cutting does not come within the allowable

value, proceed to reduce the cutting feed rate F, set Ts to a lower value or review the

program.

(Note

2)

In the steady state,

∆

R is constant. However, it is not constant with command start and stop

transitions. Under command start and stop conditions, therefore, the tracking coordinate

should be as shown in the figure below.

Start/stop

Command

Tracking

∆

R

∆

R

1

2

1

2

1

R

F × 10

3

60

1

24

1

2

1

R

F × 10

3

60

F

R

F

R

Summary of Contents for EZMotion-NC E60 Series

Page 1: ......

Page 15: ...I OPERATION SECTION ...

Page 361: ...II MACHINE OPERATION MANUAL ...

Page 399: ...III SETUP ...

Page 472: ...IV APPENDIXES ...

Page 510: ......