3. Tool Offset (M system)

3.1 Tool Offset

I

-115

Refer to "3 (I). Tool Offset (L system)" for L system.

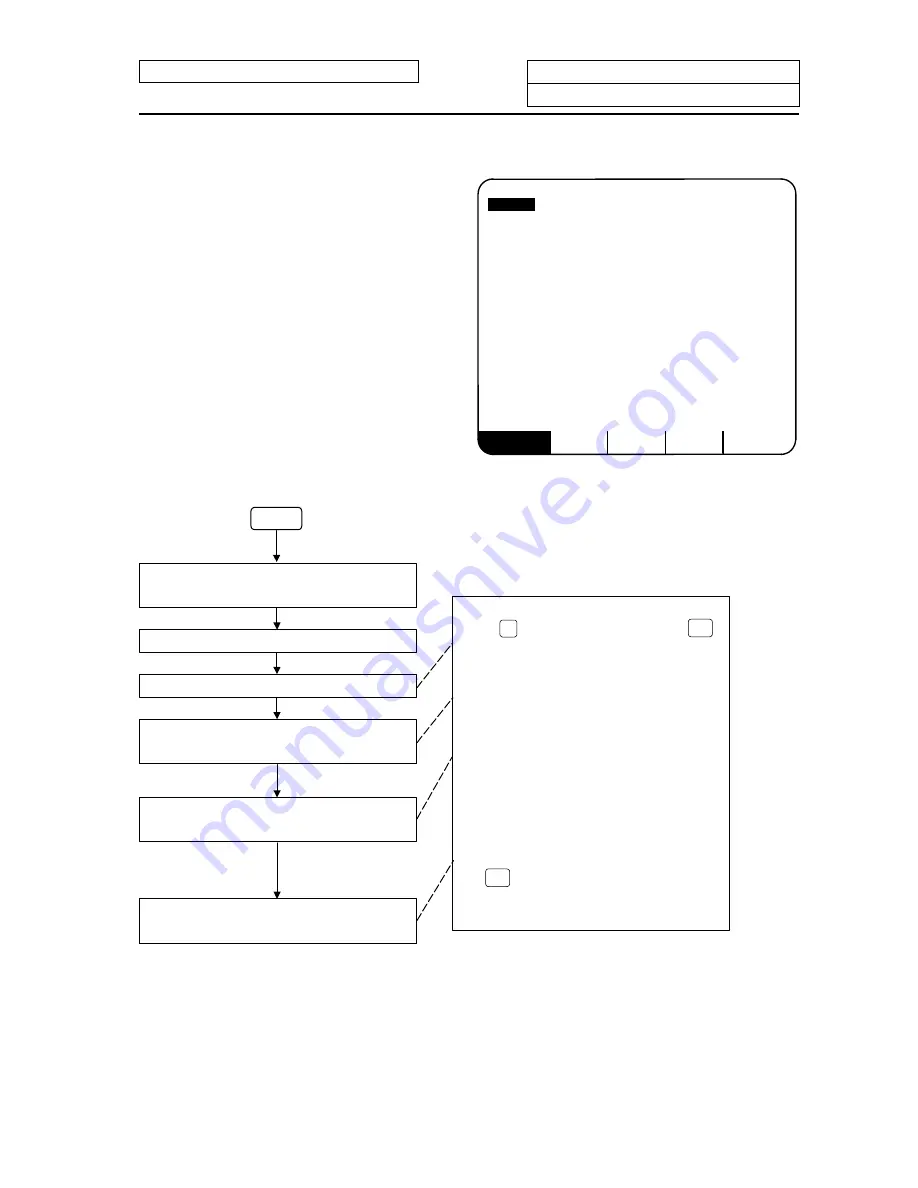

(3) Tool offset data setting by tool length measurement

OFFSET

REGIST

LIFE

MENU

[TOOL OFFSET]

TOOL

1.1/ 2

#A:ABS.

#I:INC. [MACHINE] Z 0.000

SURFACE

#O = 50.000

#

1 0.000

11 300.000

2 50.000

12 50.000

3 100.000

13 250.000

4 0.000

14 50.000

5 100.000

15 150.000

6 60.000

16 80.000

7 20.000

17 200.000

8 150.000

18 150.000

9 20.000

19 500.000

10

0.000

20

100.000

T

0 M

#( ) DATA( )

1) Tool length measurement I

Position the tool to the machine coordinate

zero point.

START

Select a measurement tool.

Set the absolute value setting mode.

Turn ON the machine operation board

"TLM" switch.

Move the tool to the measurement point by

making jog feed or manual handle feed.

Upon completion of measurement, specify

the tool offset number.

Select the TOOL OFFSET screen.

Enter

A

in # ( ), then press the

INPUT

key. "#A: ABS." is displayed in reverse

video.

To message "TLM" is displayed on the

TOOL OFFSET screen.

0 is displayed in DATA ( ) field.

The measurement value is displayed in

DATA ( ) field in sequence.

The measurement value is also displayed

under [TLM].

The current value of the measurement axis

is displayed under [MACHINE] Z.

Set the offset number in # ( ) and press

the

INPUT

key.

The measurement data is displayed at the

position of the specified offset number.

Setting and display on the TOOL

OFFSET screen

(Note)

For operation procedure, see Machine Operation manual.

Summary of Contents for EZMotion-NC E60 Series

Page 1: ......

Page 15: ...I OPERATION SECTION ...

Page 361: ...II MACHINE OPERATION MANUAL ...

Page 399: ...III SETUP ...

Page 472: ...IV APPENDIXES ...

Page 510: ......