4. Parameters (User)

4.3 I/O Parameters

I

-156

4.3 I/O Parameters

Pressing the menu key

I/O PARA

displays the I/O BASE PARAM screen.

There are basically two types of input/output parameters which must be set when inputting, outputting

or referring to data, or when performing tape operation. One type is the parameters related to the

input/output device. The baud rate, etc., is set according to each device. Up to five types of

input/output devices can be registered. The other type of input/output parameters is the I/O base

parameters which determine which device is connected to which channel per input/output application.

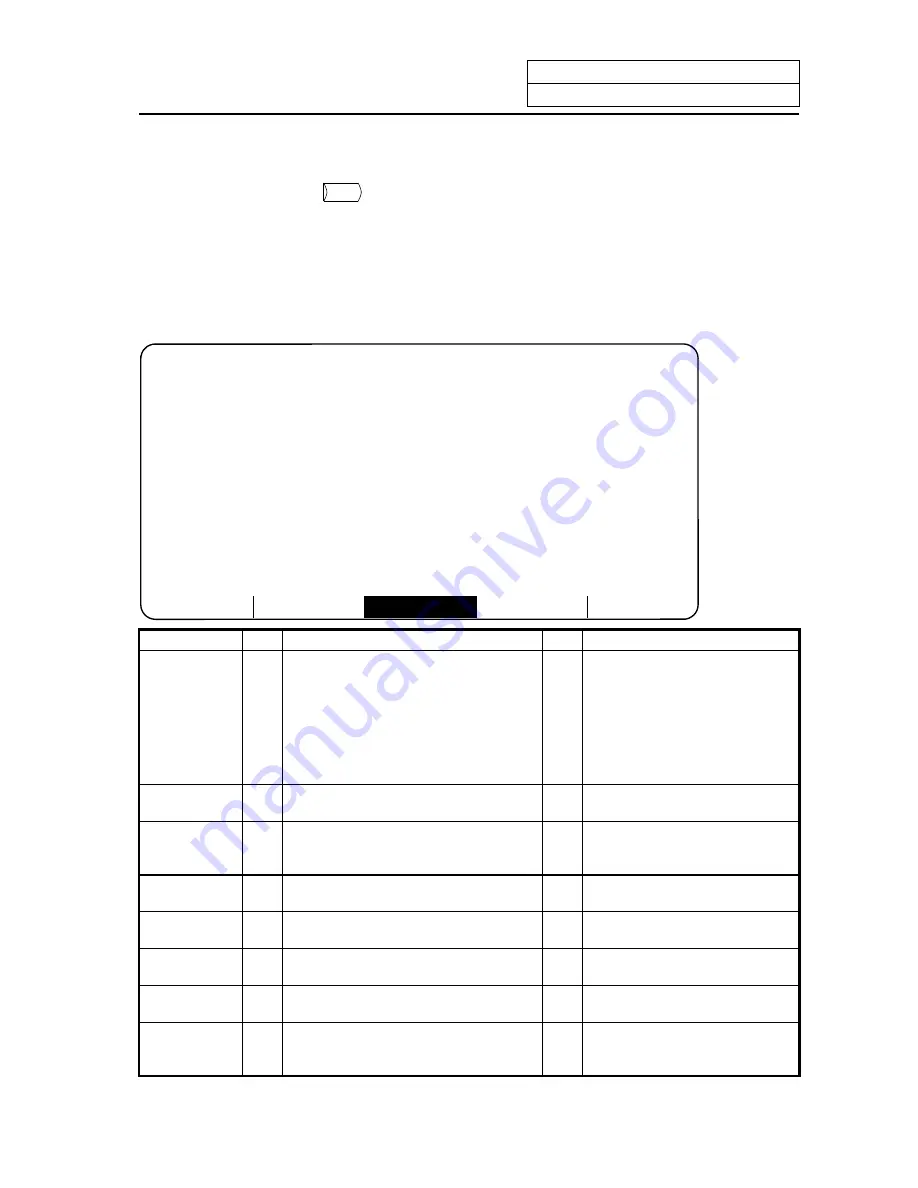

4.3.1 I/O BASE PARAM

[I/O BASE PARAM]

PARAM 2.1/7

<I/O>

# <PORT No.>

# <DEV. No.>

<DEV.NAME>

DATA IN

9001

0

9002

0

DATA OUT

9003

0

9004

0

NC RUNNING

9005

0

9006

0

MACRO PRINT

9007

0

9008

0

PLC IN/OUT

9009

0

9010

0

REMOTE PROG IN

9011

0

9012

0

RIN

EXT UNIT

9013

0

9014

0

# ( ) DATA( )

WORK PROCESS

I/O PAR

SETUP MENU

<I/O>

#

<PORT No.>

#

<DEV. No.> <DEV. NAME>

Specify the board No. to which the serial

input/output device is connected to 2.

Set the input/output device No. for

each application.

The device Nos. are 0 to 4 and

correspond to the input/output

device parameters.

The device name set in the

input/output device parameter is

also displayed for identification.

DATA IN

9001 Specify the port for inputting the data such

as machine program and parameters.

9002 Specify the No. of the device that

inputs the data.

DATA OUT

9003 Specify the port for outputting the data

such as machine program and

parameters.

9004 Specify the No. of the device that

outputs the data.

TAPE MODE

9005 Specify the input port for running with the

tape mode.

9006 Specify the No. of the device to be

run with the tape mode.

MACRO

PRINT

9007 Specify the output port for the user macro

DPRINT command.

9008 Specify the No. of the device for

the DPRINT command.

PLC IN/OUT

9009 Specify the port for inputting/outputting

various data with PLC.

9010 Specify the No. of the device for

the PLC input/output.

REMOTE

PROG IN

9011 Specify the port for inputting remote

programs.

9012 Specify the number of the device

used to input remote programs.

EXT UNIT

9013 Specify the port for communication with

an external unit.

9014 Specify the number of the unit

used for communication with an

external unit

Summary of Contents for EZMotion-NC E60 Series

Page 1: ......

Page 15: ...I OPERATION SECTION ...

Page 361: ...II MACHINE OPERATION MANUAL ...

Page 399: ...III SETUP ...

Page 472: ...IV APPENDIXES ...

Page 510: ......