68

English

Maintenance work

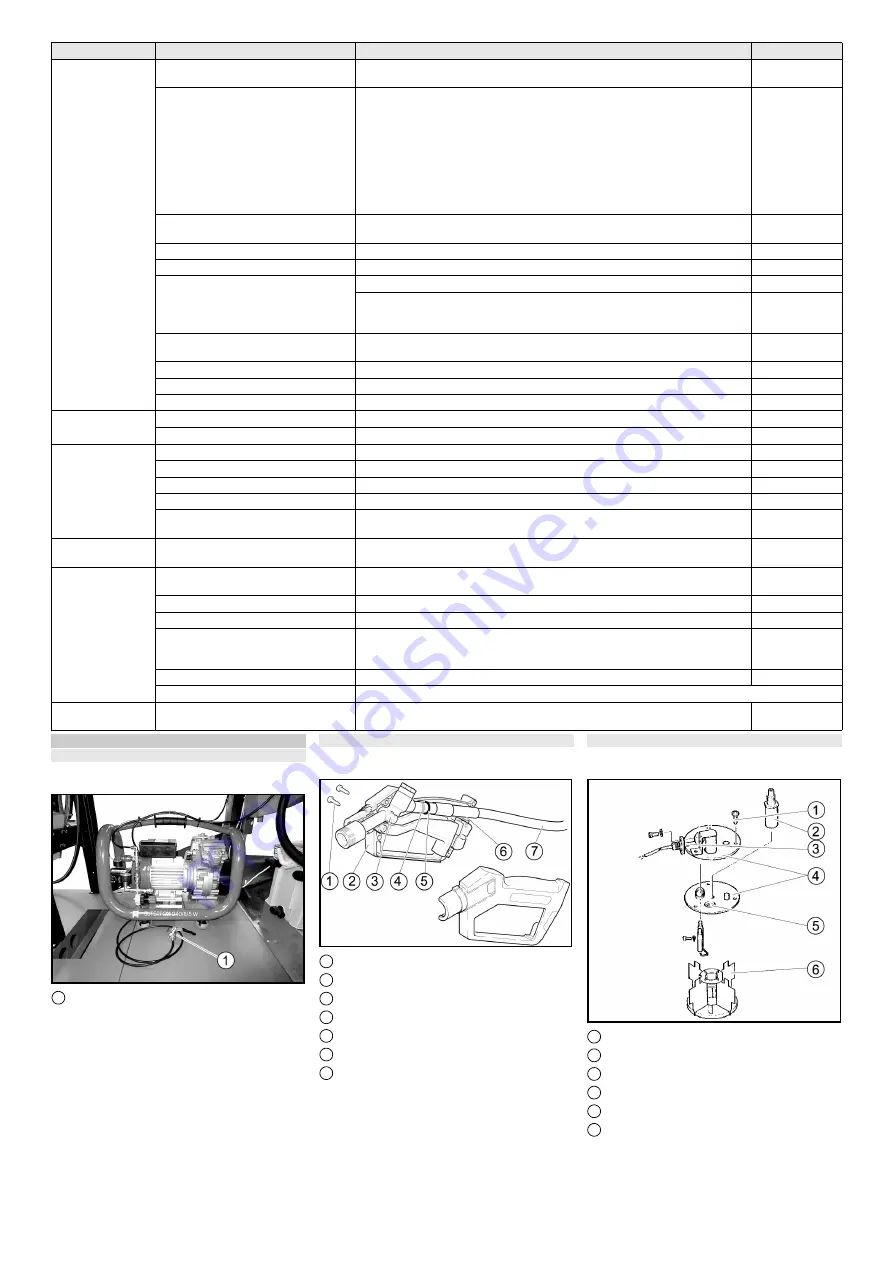

Drain the condensation water from the compressor

1. Hold the condensate drain valve over a shaft or col-

lecting container.

1

Condensate drain valve

2. Open the condensate drain valve and drain the con-

densate.

3. Close the condensate drain valve.

Grease the high pressure gun

1. Unscrew the spray lance.

2. Unscrew the 6 screws.

1

Screw

2

Handle bowl half

3

Node piece

4

Needle bearing

5

O-ring

6

Pipe / handle bowl contact surface

7

High-pressure hose

3. Remove the handle bowl half.

4. Fill the chamber for the needle bearing in the handle

bowl half with grease.

5. Grease the needle bearing and the O-ring.

6. Grease the pipe / handle bowl contact surface.

7. Screw the handle bowl halves back together.

Clean the sight glass for flame monitoring

1. Release the fuel line.

2. Pull the light sensor sideways out of the holder.

1

Screw

2

Nozzle holder

3

Light sensor

4

Cover

5

Sight glass

6

Baffle

3. Unscrew the 3 screws.

4. Remove the cover with the holder for the light sen-

sor.

After 200 operating

hours or monthly

Check the operating pressure of the high-

pressure pumps

The pressure gauge must indicate 9...10 MPa (90...100 bar). Otherwise, rectify the

fault according to the information in the section "Help with faults".

Operator

Check the antifreeze water quantity

Target value: approx. 0.5 l/min per washing tool.

Water volume greater:

Replace the node piece in the high-pressure gun.

몇

WARNING

Risk of injury, risk of damage

The high-pressure gun can move uncontrollably and cause injuries or damage if the

frost protection water volume is too high.

Be sure to replace the node piece in the high-pressure gun if the frost protection water

quantity is too high.

Water quantity smaller:

Clean the frost protection pump filter, clean the sieve in the

throttle, flush the pipe, check the direction of rotation of the pump.

Operator

Clean the detergent filter in the detergent

container

Remove the filter and rinse thoroughly with clean water.

Operator

Cleaning the filter

Clean the filter for frost protection circuit water.

Operator

Clean the storage troughs

Clean the tool storage troughs.

Operator

Checking the salt tank

Check the water level (approx. 5...25 cm above the sieve plate).

Operator

Check for deposits, empty if necessary, clean, refill with softening salt and put back

into operation. Danger of malfunctions. When topping up with softening salt, use only

the softening salt in tablet form listed in the chapter 'Accessories'.

Operator

Clean the burner

●

Clean the sight glass for flame monitoring (see section "Maintenance work").

●

Clean and check the ignition electrodes.

Operator

Lubricate the ceiling boom

Lubricate the grease nipple with a grease gun (grease 6.288-055.0).

Operator

Lubricate the door hinges.

Lubricate the hinges with grease (order no.: 6.288-072).

Operator

Preserve the locks of the doors

Spray care agent (order no.: 6.288-116) into the locks.

Operator

Quarter-yearly

Cleaning the coin slot

Open the coin acceptor door. Clean the coin slot (see section "Maintenance work"). Operator

Check the time setting

Check the time and date set on the controller and correct if necessary.

Operator

After 1000 operating

hours or half-yearly

Check the pump heads.

Replace the valves completely if the valve discs are severely damaged.

Customer Service

Replace the oil in the high-pressure pump. See Maintenance work.

Operator

Clean the flow-through vessel

Clean soot and scale from the heating coil.

Customer Service

Measure the burner

Measure the exhaust gas values, clean and adjust the burner if necessary.

Customer Service

Changing the WSO fine filter

Shut off the fresh water inlet, unscrew the filter cup, replace the filter insert, refit the

new filter insert and filter cup, open the fresh water inlet.

Operator

Annually before the

frost period

Cleaning the filter in the Power foam noz-

zle (option)

See "Cleaning the frost protection/Power foam nozzle". Determine the following clean-

ing intervals according to experience.

Operator

Annually

Safety check

Safety check according to the directives for liquid jet cleaners/accident prevention

guideline.

Customer Service

System maintenance

Maintenance contract with replacement of all wear parts.

Customer Service

Check the temperature controller

Check the function of both temperature controllers.

Customer Service

Changing the filter inlay of the active car-

bon filter WSO

Close the stop valve for fresh water (provided by the customer), unscrew and rinse out

the filter cup, replace the filter inlay with a new one, refit the filter inlay and the filter

cup, open the stop valve for fresh water and start up the system.

Operator/Custom-

er Service

Check the RO pump

Inform Customer Service. Check characteristic curve (flow rate and pressure).

Customer Service

Gas burner maintenance

Have maintenance work carried out by the burner manufacturer's Customer Service.

Every 5 years or as

required

Cleaning the fuel tank

Pump out the remaining fuel. Empty the sediment and dispose of it. Clean the inside

of the tank.

Tank cleaning ser-

vice

Time & date

Activity

Performed

By whom

Summary of Contents for SB MB

Page 39: ...Deutsch 39 Ma blatt Variante CAB SB MB Standard SB MB Comfort...

Page 40: ...40 Deutsch Ma blatt Variante SKID SB MB Standard SB MB Comfort...

Page 41: ...Deutsch 41 Ma blatt Variante SKID mit Anbausatz WSO...

Page 80: ...80 English Dimension sheet variant CAB SB MB standard SB MB comfort...

Page 81: ...English 81 Dimension sheet variant SKID SB MB standard SB MB comfort...

Page 82: ...82 English Dimension sheet variant SKID with attachment kit WSO...

Page 123: ...Fran ais 123 Fiche de dimensions variante CAB SB MB Standard SB MB Comfort...

Page 124: ...124 Fran ais Fiche de dimensions variante SKID SB MB Standard SB MB Comfort...

Page 125: ...Fran ais 125 Fiche de dimensions variante SKID avec kit de montage WSO...

Page 165: ...Italiano 165 Scheda dimensionale variante CAB SB MB Standard SB MB Comfort...

Page 166: ...166 Italiano Scheda dimensionale variante SKID SB MB Standard SB MB Comfort...

Page 167: ...Italiano 167 Scheda dimensionale variante SKID con kit di fissaggio WSO...

Page 206: ...206 Nederlands Maatblad variant CAB SB MB standaard SB MB comfort...

Page 207: ...Nederlands 207 Maatblad variant SKID SB MB standaard SB MB comfort...

Page 208: ...208 Nederlands Maatblad variant SKID met aanbouwset WSO...

Page 248: ...248 Espa ol Hoja de medidas variante CAB SB MB Standard SB MB Comfort...

Page 249: ...Espa ol 249 Hoja de medidas variante SKID SB MB Standard SB MB Comfort...

Page 250: ...250 Espa ol Hoja de medidas variante SKID con juego de montaje WSO...

Page 289: ...Svenska 289 M ttblad variant CAB SB MB Standard SB MB Comfort...

Page 290: ...290 Svenska M ttblad variant SKID SB MB Standard SB MB Comfort...

Page 291: ...Svenska 291 M ttblad variant SKID med p byggnadssats WSO...

Page 330: ...330 Suomi Mittalehti versio CAB SB MB Standard SB MB Comfort...

Page 331: ...Suomi 331 Mittalehti versio SKID SB MB Standard SB MB Comfort...

Page 332: ...332 Suomi Mittalehti versio SKID liit nt sarjalla WSO...

Page 337: ...337 2 3 4 2 A 3 3 Powerschaum STOP 1 SB MB Comfort 2 SB MB Comfort 3 SB MB Standard 4 5 6...

Page 353: ...353 1 2 2 3 4 5 6 1 7 8 9 10 11 12 13 2 3 4...

Page 354: ...354 1 2 2 3 4 5 6 1 7 8 9 10 11 3 2 3 4 1 2 3 4 5 6 7 8 9 10 11...

Page 355: ...355 SB MB Standard SB MB Comfort RO RO RO RO RO 4 60 C 0 OFF 1 2 K RCHER K RCHER...

Page 358: ...358 SB MB 6 419 070 0 25 C 0 07 0 15 MPa 0 7 1 5 bar 0 5 l min 0 0 5 l min 2 WZ 30 mm 5 C ABS...

Page 360: ...360 1000 WSO Power Power WSO RO 5...

Page 364: ...364 1 2 3 10 C F0144 S5...

Page 365: ...365 1...

Page 366: ...366 1 1 2 3 0 6 mm 4 1 3 mm 5 6 7 8 0 25 MPa 2 5 bar WAT S 202 WAT S 202 2...

Page 367: ...367 0 3 MPa 3 bar RO RO RO RO RO...

Page 373: ...373 CAB SB MB Standard SB MB Comfort...

Page 374: ...374 SKID SB MB Standard SB MB Comfort...

Page 375: ...375 SKID WSO...

Page 376: ...376...

Page 381: ...381 1 2 3 4 5 6 7 8 2 9 1 10 11 12 13 14 1 0 4 0 5 4 5 1 2 3 4 1 DP 1 2 DP 2 3 DP 3 4 DP 4 1 0...

Page 384: ...384 1 2 1 2 3 4 5 6 7 8 9 10 1 1 2 1 2 3 4 5 6 7 8 9 10 Home 1 2 3 4 5 6 Home 7 1 8 2 2 1 2...

Page 391: ...391 1 1 1 1 1 1 2 3 2 3 4 1 0 OFF 1 1 ON 2 3 1 2 1 2 3 4 5 6 7 8 9...

Page 394: ...394 1 2 3 4 5 6 7 8 9 10 11 12 13 1 2 3 4 5 6 7 8 9 10 1 2 48 3 4 24 48 5 6 7 8 1 80 100 2 3...

Page 395: ...395 B C 1 2 3 4 5 6 7 8 9 10 1 11 1 12 13 14 15 16 17 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15...

Page 397: ...397 1 2 2 3 4 5 6 1 7 8 9 10 11 12 13 2 3 4...

Page 398: ...398 1 2 2 3 4 5 6 1 7 8 9 10 11 3 2 3 4 1 2 3 4 5 6 7 8 9 10 11...

Page 399: ...399 SB MB Standard SB MB Comfort 4 60 0 OFF 1 2 K RCHER K RCHER...

Page 401: ...401 1 2 3 WSO 1 6 1 1 6 2 1 2 1 2 3 1 2 3 4 5 6 1 IP 2 3 4 1 1 2 3 4 1 2 3 4...

Page 402: ...402 SB MB 6 419 070 0 25 C 0 07 0 15 0 7 1 5 0 5 0 0 5 2 30 5 C...

Page 404: ...404 200 9 10 90 100 0 5 5 25 6 288 055 0 6 288 072 6 288 116 1000 WSO WSO...

Page 408: ...408 10 C F0144...

Page 409: ...409 1 2 3 S5 1...

Page 410: ...410 1 1 3 0 6 4 1 3 5 6 7 8 0 25 2 5 WAT S 202 WAT S 202 2...

Page 411: ...411 0 3 3...

Page 417: ...417 CAB SB MB Standard SB MB Comfort...

Page 418: ...418 SKID SB MB Standard SB MB Comfort...

Page 419: ...419 SKID WSO...

Page 420: ...420...

Page 422: ......

Page 423: ......