56

English

Maintenance work before and after the frost

period

1. Before the frost period begins, carry out mainte-

nance work "annually before the frost period be-

gins", from the section "Maintenance and care".

2. To maintain frost protection, carry out the work listed

below.

Note

Maintenance work that is not carried out on time and in

a professional manner will result in the loss of the war-

ranty in the event of frost damage.

1

Washing station heater stop valve

1

Restrictor with sieve (marked red), 1-tool version

1

Frost protection pump filter

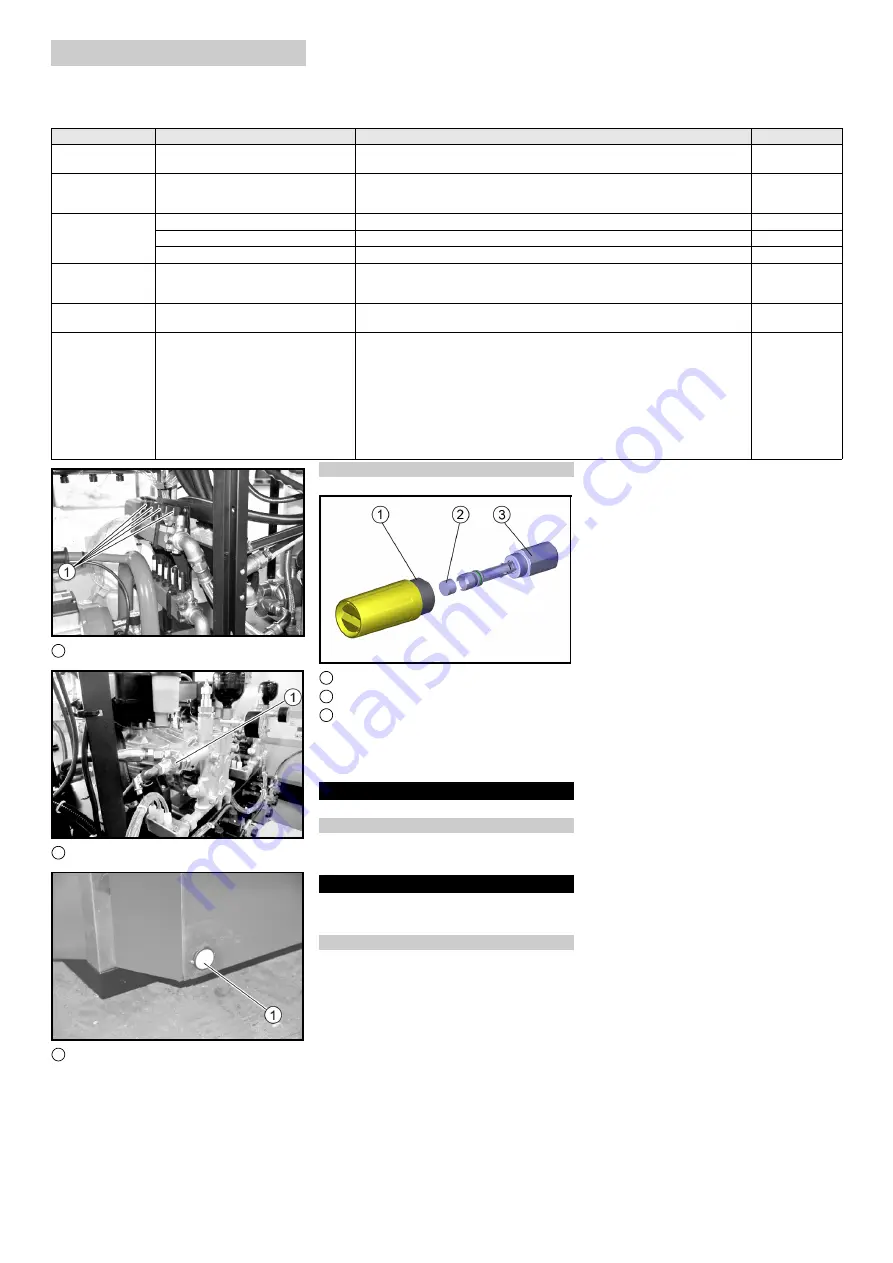

Power foamClean the nozzle

1. Unscrew the front part of the nozzle.

1

Nozzle front part

2

Filter

3

Nozzle holder

2. Remove and clean the filter.

3. Install the filter.

4. Screw the front part of the nozzle on to the nozzle

holder and tighten it.

Shutting down

1. Turn the main switch to "0/OFF".

Shutdown in the case of potential frost

1. Leave the main switch at position “1/ON”.

2. Lock the operating time at the controller.

3. Refill the fuel tank.

Shutting down

If there is no danger of frost during the shutdown period:

1. Shut off the water inlet.

2. Disconnect the power supply.

Shutting down during frost

If there is a risk of frost when shutting down, the follow-

ing additional steps must be carried out.

1. Unscrew the water supply hose and the high-pres-

sure hose.

2. Remove the RO membrane and store it frost-free.

3. Empty all float tanks, remove the hoses and drain

the water.

4. Empty the permeate buffer tank.

5. Disconnect the water pipe between the base ex-

changer and the hot water float tank.

6. Flush the system (without base exchanger) with

frost protection solution.

7. Rinse the base exchanger with concentrated salt

solution.

8. Unscrew both hoses under the flow-through kettle

and let the water drain off.

9. Blow out all water-bearing parts with oil-free com-

pressed air.

Note

During longer breaks in operation, the system, with the

exception of the base exchanger, must be rinsed with

frost protection solution to protect it from corrosion

In case of doubt, have the maintenance performed by

Customer Service.

Time & date

Activity

Performed

By whom

before the frost period Cleaning the filter in the Power foam noz-

zle (option)

Remove and clean the filter (see "Cleaning the Power foam nozzle filter"). Determine

the following cleaning intervals according to experience.

Operator

Several times a day

under frosty condi-

tions

Check the washing brushes

Check the washing brushes for dirt and ice and lock the washing brush if necessary. Operator

daily under frost con-

ditions

Clean the frost protection pump filter

Clean the filter and insert it again.

Operator

Check the hot air blowers

Are the hot air blowers in operation (also with ABS fuel tank, option)?

Operator

Check the recirculation fan

Check the function.

Operator

daily at first, later ac-

cording to experience

Check the fuel tank filling level

Is the heating oil supply sufficient until the next inspection? Take into account in-

creased consumption due to frost protection devices. Lack of fuel leads to failure and

damage to the system.

Operator

weekly during frost

Check heating ABS fuel oil tank (option)

Below 3 °C, check whether the trace heating of the fuel oil line between the heating oil

tank and SB MB is warm.

Operator

monthly or after 200

operating hours in the

event of frost, more

frequently if required

Check the frost protection water volume in

the frost protection circuit

Target value: approx. 0.5 l/min per washing tool.

Water volume greater:

Replace the node piece in the high-pressure gun.

몇

WARNING

Risk of injury, risk of damage

The high-pressure gun can move uncontrollably and cause injuries or damage if the

frost protection water volume is too high.

Be sure to replace the node piece in the high-pressure gun if the frost protection water

quantity is too high.

Water quantity smaller:

Clean the frost protection pump filter, clean the sieve in the

throttle, flush the pipe, check the direction of rotation of the pump.

Operator

Summary of Contents for SB MB

Page 39: ...Deutsch 39 Ma blatt Variante CAB SB MB Standard SB MB Comfort...

Page 40: ...40 Deutsch Ma blatt Variante SKID SB MB Standard SB MB Comfort...

Page 41: ...Deutsch 41 Ma blatt Variante SKID mit Anbausatz WSO...

Page 80: ...80 English Dimension sheet variant CAB SB MB standard SB MB comfort...

Page 81: ...English 81 Dimension sheet variant SKID SB MB standard SB MB comfort...

Page 82: ...82 English Dimension sheet variant SKID with attachment kit WSO...

Page 123: ...Fran ais 123 Fiche de dimensions variante CAB SB MB Standard SB MB Comfort...

Page 124: ...124 Fran ais Fiche de dimensions variante SKID SB MB Standard SB MB Comfort...

Page 125: ...Fran ais 125 Fiche de dimensions variante SKID avec kit de montage WSO...

Page 165: ...Italiano 165 Scheda dimensionale variante CAB SB MB Standard SB MB Comfort...

Page 166: ...166 Italiano Scheda dimensionale variante SKID SB MB Standard SB MB Comfort...

Page 167: ...Italiano 167 Scheda dimensionale variante SKID con kit di fissaggio WSO...

Page 206: ...206 Nederlands Maatblad variant CAB SB MB standaard SB MB comfort...

Page 207: ...Nederlands 207 Maatblad variant SKID SB MB standaard SB MB comfort...

Page 208: ...208 Nederlands Maatblad variant SKID met aanbouwset WSO...

Page 248: ...248 Espa ol Hoja de medidas variante CAB SB MB Standard SB MB Comfort...

Page 249: ...Espa ol 249 Hoja de medidas variante SKID SB MB Standard SB MB Comfort...

Page 250: ...250 Espa ol Hoja de medidas variante SKID con juego de montaje WSO...

Page 289: ...Svenska 289 M ttblad variant CAB SB MB Standard SB MB Comfort...

Page 290: ...290 Svenska M ttblad variant SKID SB MB Standard SB MB Comfort...

Page 291: ...Svenska 291 M ttblad variant SKID med p byggnadssats WSO...

Page 330: ...330 Suomi Mittalehti versio CAB SB MB Standard SB MB Comfort...

Page 331: ...Suomi 331 Mittalehti versio SKID SB MB Standard SB MB Comfort...

Page 332: ...332 Suomi Mittalehti versio SKID liit nt sarjalla WSO...

Page 337: ...337 2 3 4 2 A 3 3 Powerschaum STOP 1 SB MB Comfort 2 SB MB Comfort 3 SB MB Standard 4 5 6...

Page 353: ...353 1 2 2 3 4 5 6 1 7 8 9 10 11 12 13 2 3 4...

Page 354: ...354 1 2 2 3 4 5 6 1 7 8 9 10 11 3 2 3 4 1 2 3 4 5 6 7 8 9 10 11...

Page 355: ...355 SB MB Standard SB MB Comfort RO RO RO RO RO 4 60 C 0 OFF 1 2 K RCHER K RCHER...

Page 358: ...358 SB MB 6 419 070 0 25 C 0 07 0 15 MPa 0 7 1 5 bar 0 5 l min 0 0 5 l min 2 WZ 30 mm 5 C ABS...

Page 360: ...360 1000 WSO Power Power WSO RO 5...

Page 364: ...364 1 2 3 10 C F0144 S5...

Page 365: ...365 1...

Page 366: ...366 1 1 2 3 0 6 mm 4 1 3 mm 5 6 7 8 0 25 MPa 2 5 bar WAT S 202 WAT S 202 2...

Page 367: ...367 0 3 MPa 3 bar RO RO RO RO RO...

Page 373: ...373 CAB SB MB Standard SB MB Comfort...

Page 374: ...374 SKID SB MB Standard SB MB Comfort...

Page 375: ...375 SKID WSO...

Page 376: ...376...

Page 381: ...381 1 2 3 4 5 6 7 8 2 9 1 10 11 12 13 14 1 0 4 0 5 4 5 1 2 3 4 1 DP 1 2 DP 2 3 DP 3 4 DP 4 1 0...

Page 384: ...384 1 2 1 2 3 4 5 6 7 8 9 10 1 1 2 1 2 3 4 5 6 7 8 9 10 Home 1 2 3 4 5 6 Home 7 1 8 2 2 1 2...

Page 391: ...391 1 1 1 1 1 1 2 3 2 3 4 1 0 OFF 1 1 ON 2 3 1 2 1 2 3 4 5 6 7 8 9...

Page 394: ...394 1 2 3 4 5 6 7 8 9 10 11 12 13 1 2 3 4 5 6 7 8 9 10 1 2 48 3 4 24 48 5 6 7 8 1 80 100 2 3...

Page 395: ...395 B C 1 2 3 4 5 6 7 8 9 10 1 11 1 12 13 14 15 16 17 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15...

Page 397: ...397 1 2 2 3 4 5 6 1 7 8 9 10 11 12 13 2 3 4...

Page 398: ...398 1 2 2 3 4 5 6 1 7 8 9 10 11 3 2 3 4 1 2 3 4 5 6 7 8 9 10 11...

Page 399: ...399 SB MB Standard SB MB Comfort 4 60 0 OFF 1 2 K RCHER K RCHER...

Page 401: ...401 1 2 3 WSO 1 6 1 1 6 2 1 2 1 2 3 1 2 3 4 5 6 1 IP 2 3 4 1 1 2 3 4 1 2 3 4...

Page 402: ...402 SB MB 6 419 070 0 25 C 0 07 0 15 0 7 1 5 0 5 0 0 5 2 30 5 C...

Page 404: ...404 200 9 10 90 100 0 5 5 25 6 288 055 0 6 288 072 6 288 116 1000 WSO WSO...

Page 408: ...408 10 C F0144...

Page 409: ...409 1 2 3 S5 1...

Page 410: ...410 1 1 3 0 6 4 1 3 5 6 7 8 0 25 2 5 WAT S 202 WAT S 202 2...

Page 411: ...411 0 3 3...

Page 417: ...417 CAB SB MB Standard SB MB Comfort...

Page 418: ...418 SKID SB MB Standard SB MB Comfort...

Page 419: ...419 SKID WSO...

Page 420: ...420...

Page 422: ......

Page 423: ......