Chapter

11 T

roubleshooting

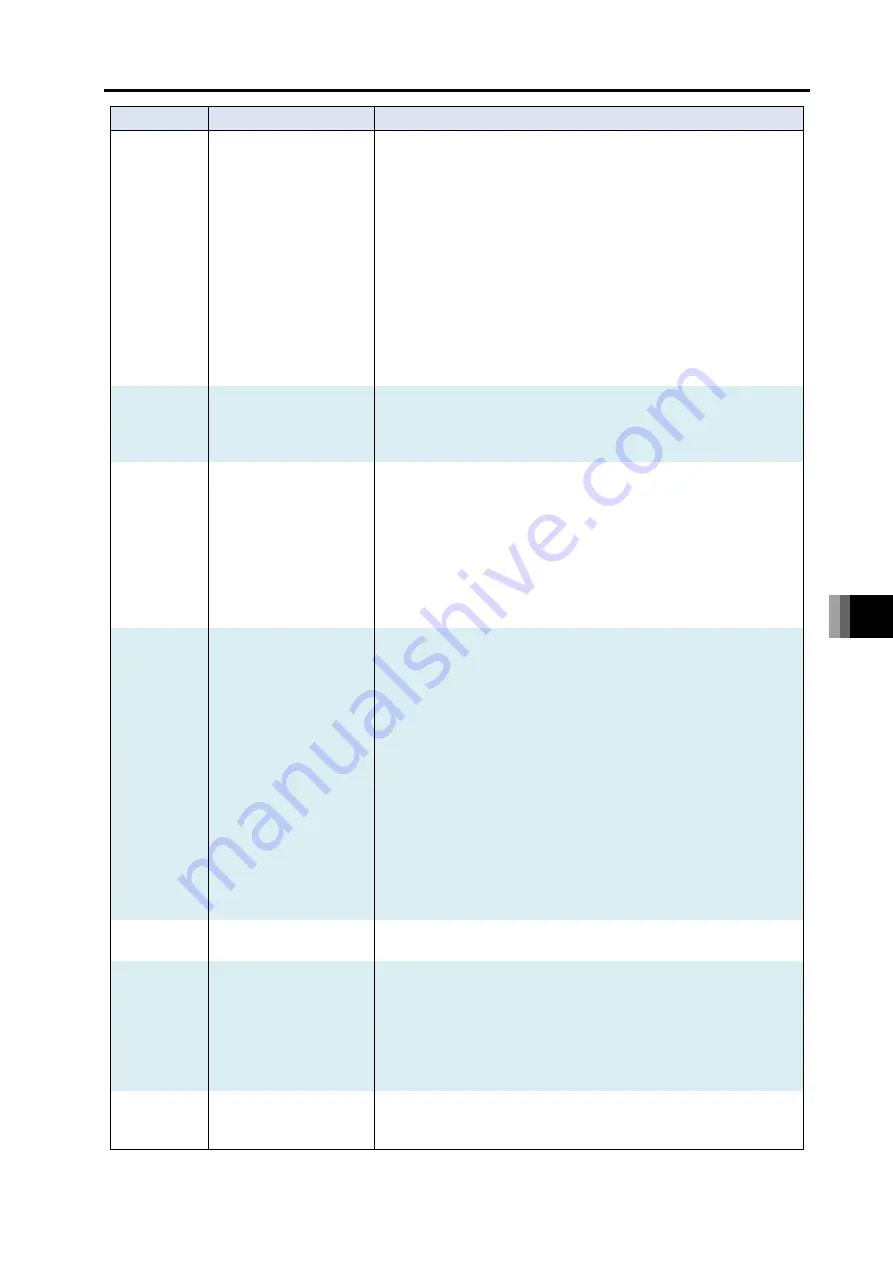

11.4 Alarm Codes of Driver Unit

11-75

ME0392-4C

Alarm code

Alarm name

Causes/countermeasures

0C0

Excessive actual speed

Cause: Motor rotation speed exceeded the allowable rotation speed.

1) The sliding resistance of the actuator is locally excessive.

2) External force is applied momentarily.

A sudden speed increase may have occurred before

detecting the servo error.

Countermeasure: This does not occur in normal operation, so confirm

that there are no assembly errors. Also, confirm

whether external force is applied in the direction of

travel.

0C1

Servo error

Cause: 2 or more seconds have passed without being able to move

after receiving the travel command.

1) Connection failure or disconnection of the actuator connecting cable.

2) The brake cannot be released (for models with brake).

3) The load on the motor is large due to external force.

4) The sliding resistance of the actuator is excessive.

Countermeasure: 1) Check the wiring status of the actuator

connecting cable.

2) If there is no problem with the 24V DC power

supplied to the control power connector of the

gateway unit, the RSEL system may be faulty.

Contact IAI.

3) Confirm that there are no assembly errors in

machine components.

4) If the load weight is within the specifications, turn OFF the

power supply and manually check the sliding resistance.

0C2

S

Driver limited

Overrun sensor detected

Cause: This indicates that a signal from the OT sensor (option)

installed at the mechanical end is detected.

1) The actuator was moved by hand or received external force

while the servo was OFF (normal detection).

2) A jog operation was made under a condition that the home

coordinates are not established and the soft stroke limit

would not work properly.

3) The home position achieved by home return is not correct,

or in the case of an absolute type controller the coordinates

have shifted due to an inappropriate absolute reset

position.

4) There is a mismatch between the sensor characteristics

and the setting in Parameter No.19 “Overrun sensor input

polarity”, or the wiring layout is wrong.

5) There is a mistake in the combination of the controller and

actuators, or the setting in Parameter No. 3 and 4 “Soft

Limit” or Parameter No. 77 “Ball Screw Lead Length” is

inappropriate.

Countermeasure: If 1) or 2) is suspected, move the actuator in the

opposite direction by hand.

If this error occurred inside the effective stroke

range, 3), 4), or 5) is a likely cause.

If 3) is suspected, check the home position. Conduct

the absolute reset again if it is the absolute type.

If 4) or 5) is suspected, please contact IAI.

0C5

A

Driver limited

Unauthorized control

system transition

command

Cause: 1) Operation was switched to normal position control operation

during “damping control” operation.

2) Operation was switched to “damping control” operation

during normal position control operation.

Countermeasure: For both 1) and 2), change the sequence so that the

next operation is performed after confirming that

positioning complete signal PEND is ON.

11.4 Alarm Codes of Driver Unit

ME0392-4C

11-76

Alarm code

Alarm name

Causes/countermeasures

0CE

Control power supply

voltage drop

Cause: Gateway unit control power supply voltage has dropped to or

below 16.8V (70% of 24V DC).

1) Control power supply voltage drop

2) 24V DC power supply capacity is insufficient

3) The power supply voltage has dropped.

4) Malfunction of parts inside the RSEL system

Countermeasure: 1) Confirm that voltage of 24V DC ±10% is being

applied to the gateway unit control power

connector. If the voltage is low, the 24V DC

power supply may have failed.

2) Insufficient power capacity for actuator drive. Confirm

the required power capacity in the instruction manual

and replace the 24 VDC power supply.

3) 4) Contact IAI.

0D2

A, D

Driver limited

Excessive motor power

supply voltage

Cause: There is a possibility of component failure inside the RSEL

system.

Countermeasure: If it occurs frequently, the probability of RSEL

system failure is high. Contact IAI.

0D6

Fan error detection

Cause: 1) The number of revolution of the fan in the fan unit mounted

on the driver unit has dropped by 50%.

2) The number of revolution of the fan unit mounted on the

200V system power supply unit has dropped by 50%. (When

detail code is 0001H in the alarm list in the teaching tool)

Countermeasure: 1) 2) Replace the fan unit.

Refer to [12.3.2 How to Replace Fan Unit] and

[12.3.3 How to Replace Fan Unit for 200V Driver

Unit (page 12-8)] for how to make replacement.

0D8

Deviation overflow

Cause: The position deviation counter overflowed.

1) The unit decelerated or stopped due to the influence of

external force or overload during travel.

2) The excitation detection operation after power ON is

unstable.

3) The power supply voltage has dropped.

4) The servo gain number is too low.

Countermeasure: 1) This occurs when the actuator cannot operate

according to commands. Check the load

condition, such as whether the workpiece is

interfering with surrounding objects, whether the

brake is released, etc., and resolve the cause.

2) There may be an overload, so review the payload

and start home return again.

3) Check power supply voltage.

4) Adjust the servo gain number.

0D9

Software stroke limit over

error

Cause: The present position of the actuator exceeds the software stroke limit

Countermeasure: Return to the software stroke limit range.

0DC

Push-motion operation

range exceeded error

Cause: 1) The push-back force was too strong after pushing was completed,

pushing back to the push-motion start setting position.

2) The workpiece was pushed during the approach operation

before shifting to push-motion.

Countermeasures: 1) Re-set and reduce the push-back force.

2) Correct the push-motion start setting position to

the front and shorten the approach distance.

0ED

P, A

Driver limited

Absolute encoder error

detection 1

Cause: The present position changed while reading or saving absolute

data.

Countermeasures: Do not apply vibration to the actuator.

Summary of Contents for R-unit RSEL

Page 2: ......

Page 5: ...ME0392 4C 2 Quick Start Guide Japanese Only ...

Page 32: ...Actuator Coordinate System Intro 18 ME0392 4C 2 Slider type 3 Table type 0 0 0 0 ...

Page 50: ...Chapter 1 RSEL System 1 4 Installation 1 13 ME0392 4C ...

Page 244: ...Chapter 4 Unit connection Installation and Wiring 4 5 PIO Circuit 4 32 ME0392 4C ...

Page 316: ...Chapter 5 Operation 5 10 ELECYLINDER Operation 5 52 ME0392 4C ...

Page 438: ...Chapter 6 Field Network PIO SIO 6 5 Example of Connectivity Setting 6 120 ME0392 4C ...

Page 532: ...10 6 Servo Gain Adjustment 10 90 10 7 Parameter Configuration Advanced Use 10 93 ...

Page 638: ...Chapter 10 Parameter 10 7 Parameter Configuration Advanced Use 10 106 ME0392 4C ...

Page 838: ...Chapter 14 Warranty 14 Warranty 14 3 ME0392 4C ...

Page 843: ......

Page 844: ......