Chapter 10 Parameter

10.3

Parameter List (Driver Unit)

10-74

ME0392-4C

[BU Velocity Loop Integral Gain (Parameter No. 154)]

No.

Name

Unit

Input range

Default initial value setting

154 BU velocity loop integral

gain

-

1 to 99,999,999

In accordance with actuator

When Parameter No. 152 “High Output Setting” is enabled and Parameter No. 144 “GS

Magnification Upper Limit” is set to 100 or less, the setting of this parameter is enabled for

Velocity Loop Integral Gain.

For details, refer to Parameter No. 32 “Velocity Loop Integral Gain (page 10-60”.

For the conditions for using this item, refer to [Selection and use of Velocity Loop Proportional

Gain and Velocity Loop Integral Gain] on the bottom of page 10-60.

[ABS Battery Retaining Time (Parameter No. 155)]

No.

Name

Unit

Input range

Default initial value setting

155 ABS battery retaining time

-

0: 20 days

1: 15 days

2: 10 days

3: 5 days

0

This function is limited to the simple absolute specification. Set encoder positional data retention

time after turning the power supply to the actuator OFF. The setting is available in 4 levels. The

lower the motor rotation speed setting is, the longer the retention time of the positional data can

be. If there is a possibility of external force moving the workpiece conveying components of the

actuator such as the slider or rod while power is OFF, refer to the following table and calculate

motor revolution based on movement speed and set the value of this parameter faster. If the

motor revolution exceeds the set value, positional data will be lost.

The motor rotation speed can be calculated with the equation below.

Motor revolution [r/min] = Movement speed [mm/s] / Actuator lead [mm] x 60 [s/min]

For details, refer to [3.7.4 General Specifications (page 3-119)].

Parameter

No.155

settings

Upper limit of encoder rotation speed when

power is OFF [r/min]

Battery

retaining

time

guideline

[days]

Retaining time

per 1 hour of

charge time

(guideline)

[h]

If connected actuator

is not RCA2-***NA

If connected actuator

is RCA2-***NA

0

100

75

20

6.6

1

200

150

15

5.0

2

400

300

10

3.3

3

800

600

5

1.6

24V AC servo motor specification and

stepper motor specification only

Stepper motor specification only

10.3 Parameter List (Driver Unit)

ME0392-4C

10-75

[Enabled/Disabled Axis Select (Parameter No. 158)]

No.

Name

Unit

Input range

Default initial value

setting

158 Enabled/disabled axis

select

-

0: Enabled

1: Disabled

0

Set this parameter disabled when an operation is required with number of axes less than that of

purchased.

A disabled axis is not available to select in “RSEL Axis Setting”.

Disabling an axis after the RSEL axis setting is established should require establishment of the

RSEL axis setting again.

[Delay Time after Shutdown Release (Parameter No. 165)]

No.

Name

Unit

Input range

Default initial value setting

165 Delay Time after

Shutdown Release

ms

0 to 10,000

0

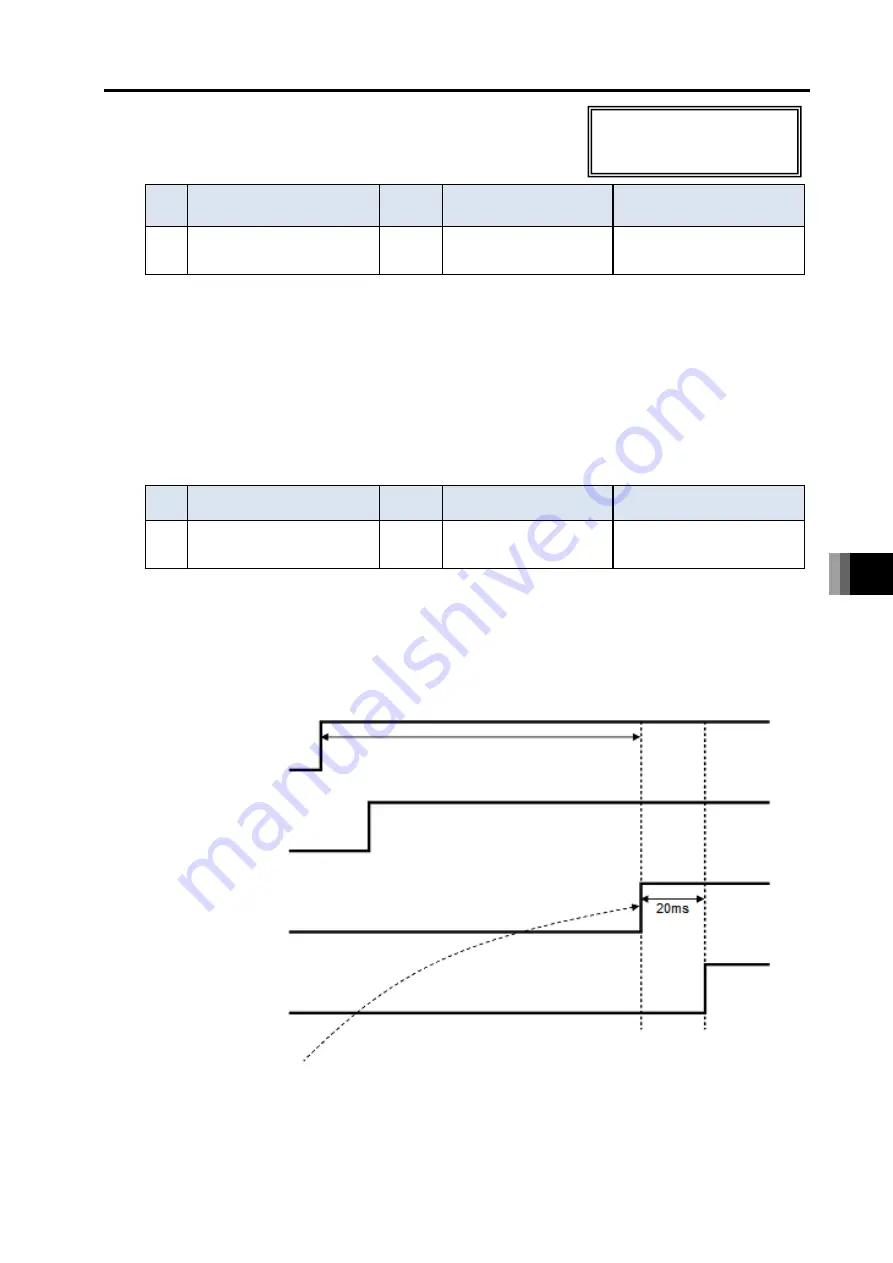

The setting should be established for the duration till it gets available to have the servo on when

it takes time for the rising of the cutoff source due to such a reason as the external drive cutoff

circuit at the cancellation of the emergency stop. There is no need of making a change when

having a drive cutoff only on an internal drive cutoff relay in a controller.

24V AC servo motor specification,

DC brush-less motor specification

and Stepper motor specification only

Shutdown

・

Emergency Stop

・

Enable Switch etc.

RSEL Servo-ON

command

Driver Servo-ON

command reception

Servo-ON complete

If the on-edge 2) of external servo-ON command came after the point of passing SDDT

time 1), the condition becomes reception of controller internal servo-ON command at

the point of 2).

1)

2)

Summary of Contents for R-unit RSEL

Page 2: ......

Page 5: ...ME0392 4C 2 Quick Start Guide Japanese Only ...

Page 32: ...Actuator Coordinate System Intro 18 ME0392 4C 2 Slider type 3 Table type 0 0 0 0 ...

Page 50: ...Chapter 1 RSEL System 1 4 Installation 1 13 ME0392 4C ...

Page 244: ...Chapter 4 Unit connection Installation and Wiring 4 5 PIO Circuit 4 32 ME0392 4C ...

Page 316: ...Chapter 5 Operation 5 10 ELECYLINDER Operation 5 52 ME0392 4C ...

Page 438: ...Chapter 6 Field Network PIO SIO 6 5 Example of Connectivity Setting 6 120 ME0392 4C ...

Page 532: ...10 6 Servo Gain Adjustment 10 90 10 7 Parameter Configuration Advanced Use 10 93 ...

Page 638: ...Chapter 10 Parameter 10 7 Parameter Configuration Advanced Use 10 106 ME0392 4C ...

Page 838: ...Chapter 14 Warranty 14 Warranty 14 3 ME0392 4C ...

Page 843: ......

Page 844: ......