4-39

1

Before Using the Products

2

Preparation

3

Connection

4

Setup

5

Adjustment

6

When in T

rouble

7

Supplement

Pr4.00

*

SI1 input selection

Range

Unit

Default

Related

control mode

0 to 00FFFFFFh

—

00828282h

(8553090)

P S T F

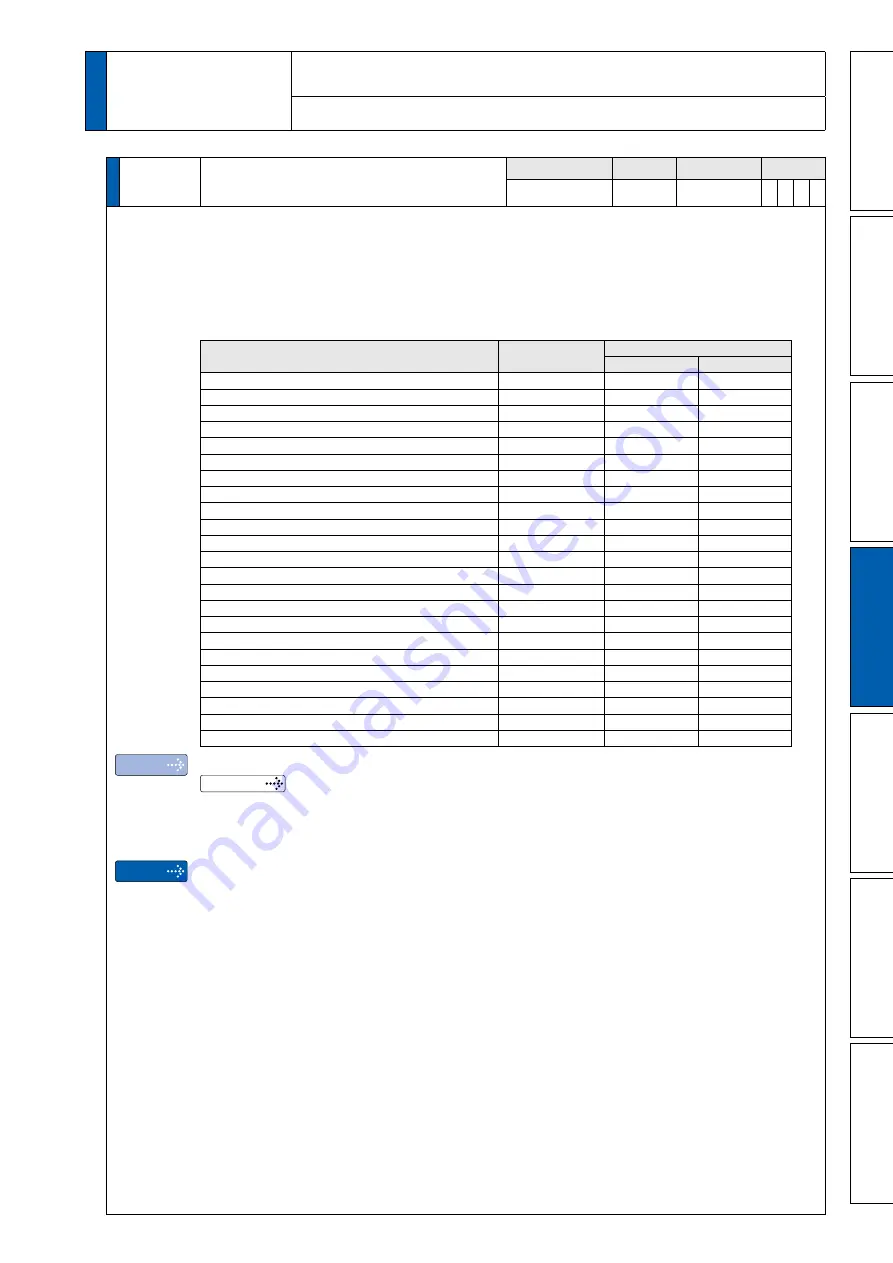

Assign functions to SI1 inputs.These parameters are presented in hexadecimals.

*

5

Hexadecimal presentation is followed by a specific control mode designation.

0 0 – – – –

* *

h : position/full-closed control

0 0 – –

* *

– – h : velocity control

0 0

* *

– – – – h : torque control

Replace

* *

with the function number.

For the function number see the table below. Logical setup is also a function number.

Title

Symbol

Setup value

a-contact

b-contact

Invalid

−

00h

Do not setup.

Positive direction over-travel inhibition input

POT

01h

81h

Negative direction over-travel inhibition input

NOT

02h

82h

Servo-ON input

*

1

SRV-ON

03h

83h

Alarm clear input

A-CLR

04h

Do not setup.

Control mode switching input

*

2

C-MODE

05h

85h

Gain switching input

GAIN

06h

86h

Deviation counter clear input

*

3

CL

07h

Do not setup.

Command pulse inhibition input

*

4

INH

08h

88h

Torque limit switching input

TL-SEL

09h

89h

Damping control switching input 1

VS-SEL1

0Ah

8Ah

Damping control switching input 2

VS-SEL2

0Bh

8Bh

Electronic gear switching input 1

DIV1

0Ch

8Ch

Electronic gear switching input 2

DIV2

0Dh

8Dh

Selection 1 input of internal command speed

INTSPD1

0Eh

8Eh

Selection 2 input of internal command speed

INTSPD2

0Fh

8Fh

Selection 3 input of internal command speed

INTSPD3

10h

90h

Speed zero clamp input

ZEROSPD

11h

91h

Speed command sign input

VC-SIGN

12h

92h

Torque command sign input

TC-SIGN

13h

93h

Forced alarm input

E-STOP

14h

94h

Inertia ratio switching input

J-SEL

15h

95h

Dynamic brake switching input

*

5

DB-SEL

16h

Do not setup.

Note

Caution

For input pin assignment with default setting, refer to P.3-39 Control input.

Related page

P.3-52

<Example of change>

To change the default setting “Negative direction over-travel inhabitation input” (in all modes) for

b-contact to for a-contact, set the input to 00020202h.

*

For easier setting, use the setup support software PANATERM.

• Do not setup to a value other than that specified in the table.

• Do not assign specific function to 2 or more signals. Duplicated assignment will cause Err33.0 I/F

input multiple assignment error 1 or Err33.1 I/F input multiple assignment error 2.

• When measuring frequency characteristics of PANATERM, as it will automatically switchover to

position velocity control inside the driver, please set the same set value for input signal of velocity

control to be made abled during the measurement, to the set value for position control.

•

Note that the setup values are displayed in decimal on the front panel.

*

1 Servo-on input signal (SRV-ON) must be used to enable servo-on.

*

2 When using the control mode switch input (C-MODE), all control modes need to be set. If configuration

is made only for 1 or 2 modes, Err33.2“I/F input function number error 1 ”or Err33.3“I/F input function

number error 2”occurs.

• The control input pin set to invalid state does not affect any operation.

• Function (servo-on input, alarm clear, etc.) to be used in multiple control modes must be assigned to

the same pin with correct logical arrangement. Incorrect setting will cause Err33.0 I/F input multiple

assignment error 1 or Err33.1 I/F input multiple assignment error 2.

*

3 Deviation counter clear input (CL) can be assigned only to SI7 input. Wrong assignment will cause

Err33.6 Counter clear assignment error.

*

4 Command pulse inhibition input (INH) can only be assigned to SI10 inputs. If the input is assigned to

other than that,Err33.7 “Command pulse input inhibition input ”occurs.

*

5 When using the Dynamic brake switch input, all control modes need to set after set Pr 6.36(Dynamic

brake operation input) =1.If configurationis mode only for 1 or 2 mode, Err33.2”I/F input function number

error 1” or Err33.3”I/F input function number error 2” occurs.For more information.

4

1. Details of parameter

Setup

[Class 4] I/F monitor setting

Default: [ ]

Buy: www.ValinOnline.com | Phone 844-385-3099 | Email: [email protected]