3 - 15

3. CC-LINK COMMUNICATION FUNCTIONS

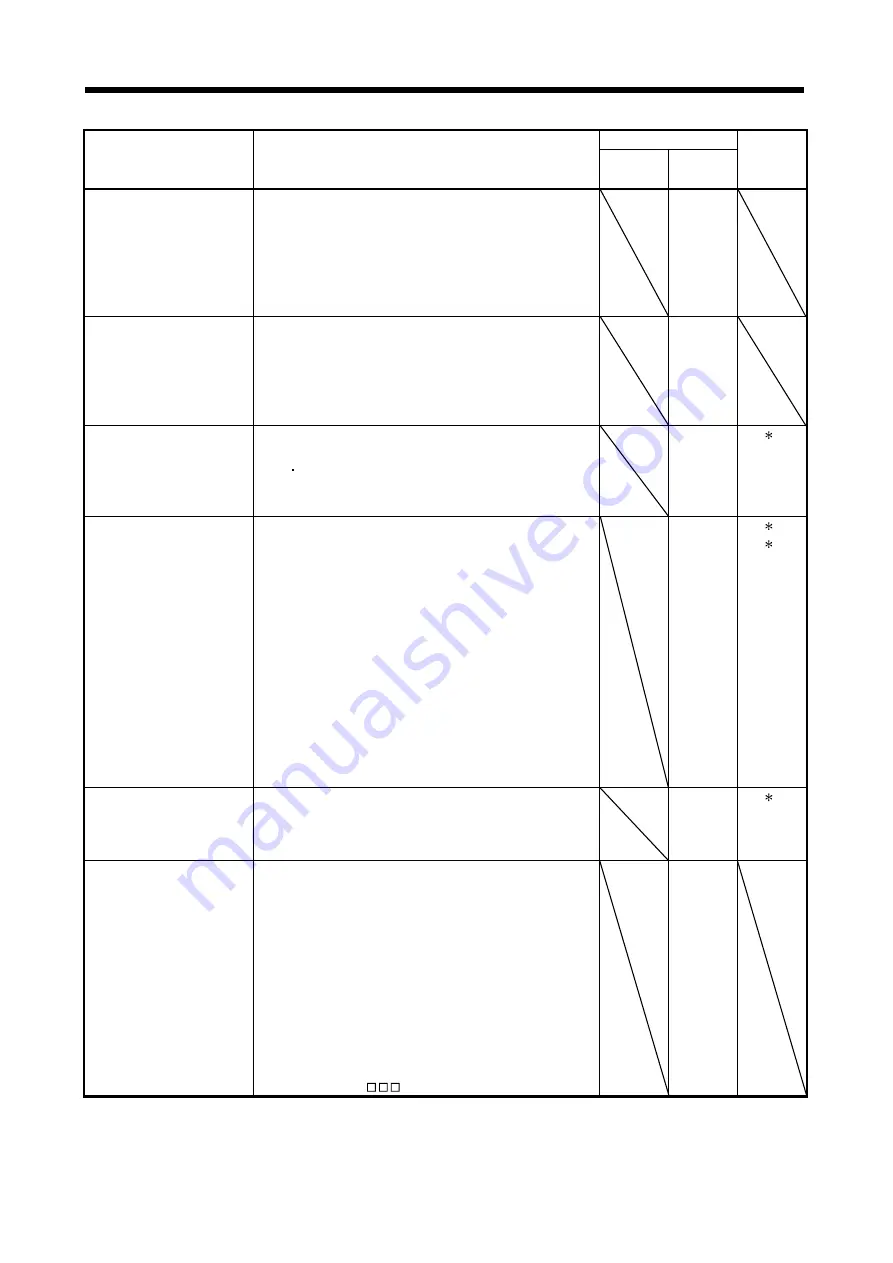

Device No.

Signal name

Description

1 station

occupied

2 stations

occupied

Remarks

Position instruction demand

When RY(n+2)0 is turned ON, the point table No. or position

command data set to remote register RWwn+4/RWwn+5 is

set.

When it is set to the servo amplifier, the answer code

indicating normal or error is set to RWrn+2. At the same time,

RX(n+2)0 turns ON.

Refer to section 3.6.3 for details.

RY(n+2)0

Speed instruction demand

When RY(n+2)1 is turned ON, the point table No. or speed

command data set to remote register RWwn+6 is set.

When it is set to the servo amplifier, the answer code

indicating normal or error is set to RWrn+2. At the same time,

RX(n+2)1 turns ON.

Refer to section 3.6.3 for details.

RY(n+2)1

Internal torque limit selection

Turning RY(n+2)6 OFF makes the torque limit value of

parameter No. PA11 (forward rotation torque

limit) parameter No. PA12 (reverse rotation torque limit)

valid, and turning it ON makes that of parameter No. PC35

(internal torque limit). (Refer to section 4.6.3)

RY(n+2)6 1

Proportion control

When RY(n+2)7 is turned ON, the speed amplifier is switched

from the proportional integral type to the proportional type.

If the servo motor at a stop is rotated even one pulse by an

external factor, it develops torque in an attempt to

compensate for a position shift. When the shaft is locked

mechanically after Movement finish (RXnC) is turned OFF, for

example, turning Proportion control (RY(n+2)7) ON as soon

as Movement finish (RXnC) turns OFF allows control of

unnecessary torque developed in an attempt to compensate

for a position shift.

When the shaft is to be locked for an extended period of time,

turn Internal torque limit selection (RY(n+2)6) ON

simultaneously with Proportion control (RY(n+2)7) to make

the torque not more than the rated torque using Internal

torque limit (parameter No. PC35).

RY(n+2)7 1

2

Gain changing

When RY(n+2)8 is turned ON, the load inertia moment ratio

and the corresponding gain values change to the values of

parameter No. PB29 to PB32. To change the gain using

RY(n+2)8, make the auto tuning invalid.

RY(n+2)8 1

Position/speed specifying

system selection

Select how to give a position command/speed command.

(Refer to section 3.6.3.)

OFF: Remote input-based position/speed specifying system

Specifying the point table No. with Point table No.

selection (RYnA to RYnE) gives a position

command/speed command.

ON : Remote register-based position/speed specifying

system

Setting the instruction code to the remote register

(RWwn+4 to RWwn+6) gives a position

command/speed command.

Set the parameter No. PC30 (direct specification

selection) to "

2".

RY(n+2)A

Summary of Contents for MELSERVO MR-J3-xT

Page 22: ...8 MEMO ...

Page 156: ...4 46 4 SIGNALS AND WIRING MEMO ...

Page 276: ...7 26 7 MR Configurator MEMO ...

Page 324: ...10 16 10 SPECIAL ADJUSTMENT FUNCTIONS MEMO ...

Page 418: ...14 66 14 OPTIONS AND AUXILIARY EQUIPMENT MEMO ...