3 - 4

3. CC-LINK COMMUNICATION FUNCTIONS

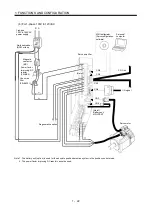

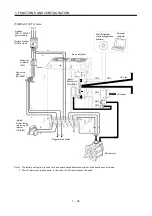

(4) How to wire the CC-Link connector (CN1)

(a) Strip the sheath of the cable and separate the internal wires and braided shield.

(b) Strip the sheaths of the braided shield and internal wires and twist the cores.

3-core twisted pair cable

Approx. 10mm (0.394in.)

Braided shield

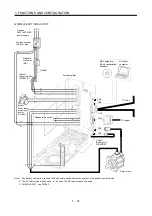

(c) Match and twist the wires and braided shield of the cable connected to the preceding axis or PLC and

the corresponding wires and braided shield of the cable connected to the subsequent axis.

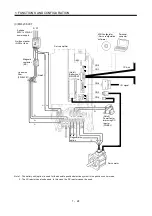

(d) For the last axis, work the termination resistor supplied to the CC-Link master unit as shown below.

Termination register

Cut

Remove sheath

(10mm (0.394in.))

Fold lead wire

(10mm (0.394in.))

Cut

Remove sheath

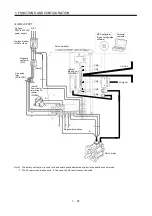

(e) Insert the core of the cable into the opening and tighten it with a flat-blade screwdriver so that it will not

come off. (Tightening torque: 0.5 to 0.6N m) When inserting the wire into the opening, make sure that

the terminal screw is fully loose.

Flat blade screwdriver

Tip thickness 0.4 to 0.6mm (0.016 to 0.024in.)

Full wide 2.5 to 3.5mm (0.098 to 0.138in.)

Loosen

Tighten

CC-Link connector (CN1)

To the preceding station

or PLC

To the next

station

POINT

Do not solder the cores as it may cause a contact fault.

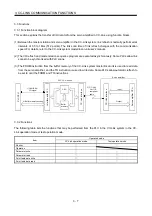

Use of a flat-blade torque screwdriver is recommended to manage the screw tightening torque. The

following table indicates the recommended products of the torque screwdriver for tightening torque

management and the flat-blade bit for torque screwdriver. When managing torque with a Phillips bit, please

consult us.

Product Model

Maker/Representative

Torque screwdriver

N6L TDK

Nakamura Seisakusho

Bit for torque screwdriver

B-30, flat-blade, H3.5 X 73L

Shiro Sangyo

Summary of Contents for MELSERVO MR-J3-xT

Page 22: ...8 MEMO ...

Page 156: ...4 46 4 SIGNALS AND WIRING MEMO ...

Page 276: ...7 26 7 MR Configurator MEMO ...

Page 324: ...10 16 10 SPECIAL ADJUSTMENT FUNCTIONS MEMO ...

Page 418: ...14 66 14 OPTIONS AND AUXILIARY EQUIPMENT MEMO ...