An integrating method of measurement totalizes the weighted time. The weighted time results from the char-

acteristic curve. For this, the time that is associated with the present current value is determined from the

characteristic curve. Once the weighted time exceeds the value 1, the stage operates.

When the measured value falls below the pickup value by 1.045 times (0.95 x 1.1 x threshold value), the

dropout is started. The pickup will be indicated as clearing. You can influence the dropout behavior via setting

parameters. You can select between instantaneous dropout (totalized time is deleted) or dropout according to

the characteristic curve (reduction of totalized time depending on the characteristic curve). The dropout

according to the characteristic curve (disk emulation) is the same as turning back a rotor disk. The weighted

reduction of the time is started from 0.9 of the set threshold value.

The characteristic curve and associated formulas are shown in the Technical data.

Influence On the Operate Curve

The current pickup threshold is decreased proportional to the voltage decrease. Consequently, for a constant

current I the I/Threshold-value ratio is increased and the operate time is reduced. Compared with the standard

curves represented in the Technical Data, the operate curve shifts to the left side as the voltage decreases.

Measuring-Voltage Failure Detection

In case of a measuring-voltage failure detection the input voltage value is automatically set to V

rated

, so that

the pickup threshold factor will be 1.

Blocking of the Time Delay

You can use the binary input signal

>Block delay & op.

to prevent the start of the time delay and thus

also the operate signal. A running time delay is reset. The pickup is indicated and the fault logging and

recording takes place.

Blocking of the Operate Delay and the Operate Signal via the Device-Internal Inrush-Current Detection Function

Blocking of the operate delay and the operate signal via the device-internal Inrush-current detection function

is described in chapter

Application and Setting Notes

Parameter:

Blk. w. inrush curr. detect.

•

Default setting

(_:11491:27) Blk. w. inrush curr. detect.

=

no

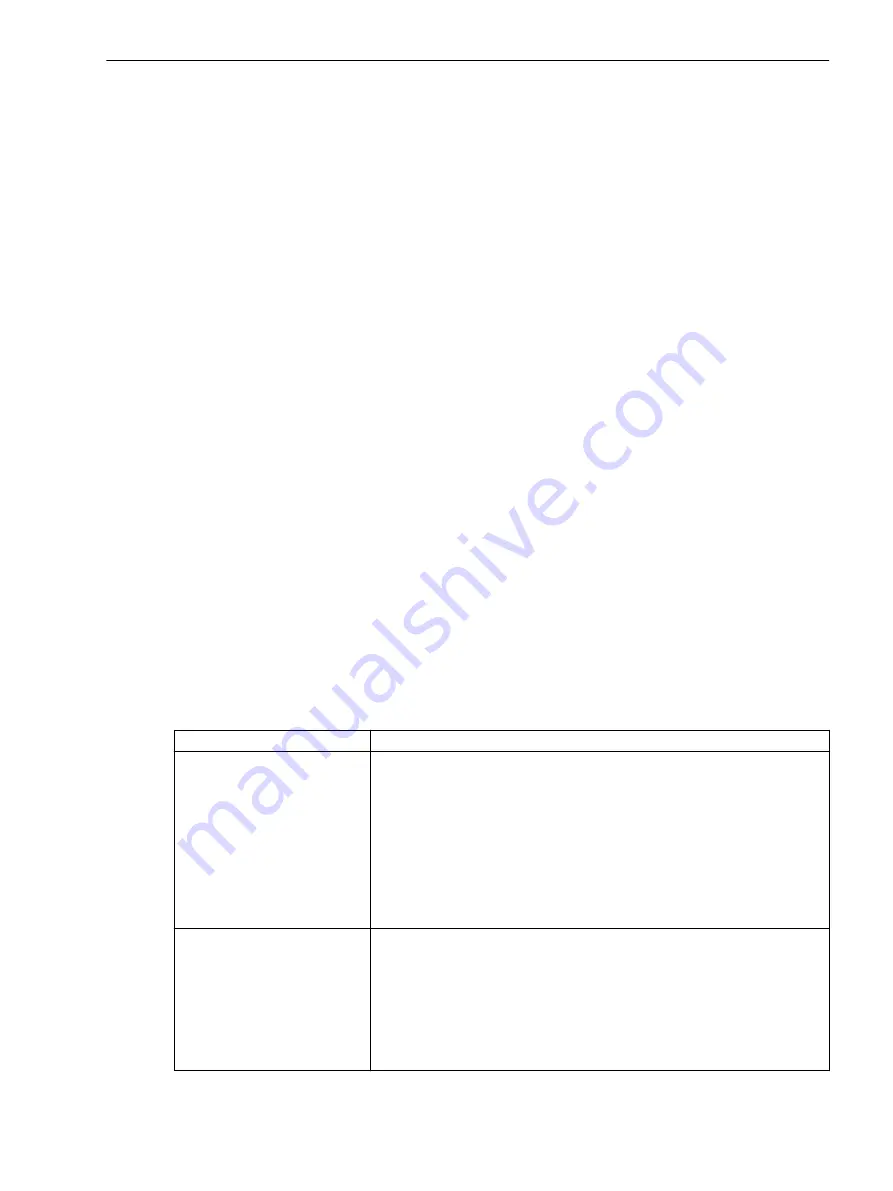

Parameter Value

Description

no

The transformer inrush-current detection does not affect the stage. Select

this setting in the following cases:

•

In cases where the device is not used on transformers.

•

In cases where the device is used on transformers and the threshold

value of the stage is set above the maximum inrush current of the

transformer. This applies, for example, to the high-current stage that is

set according to the short-circuit voltage Vsc of the transformer in such

a way that the stage only picks up on faults from the high-voltage side.

The transformer-inrush current cannot become larger than the

maximum transmittable short-circuit current.

yes

When the transformer inrush-current detection detects an inrush current

that would lead to a tripping of the stage, the start of the time delay and

tripping of the stage are blocked.

Select this setting if the device is used on transformers and the threshold

value of the stage is set below the maximum inrush current of the trans-

former. This applies to the overcurrent-protection stage, which is used as a

backup stage with grading time for faults on the undervoltage side of the

transformer.

6.4.3.2

Protection and Automation Functions

6.4 Voltage-Dependent Overcurrent Protection, Phases

SIPROTEC 5, Overcurrent Protection, Manual

363

C53000-G5040-C017-8, Edition 07.2017

Summary of Contents for 7SJ82

Page 8: ...8 SIPROTEC 5 Overcurrent Protection Manual C53000 G5040 C017 8 Edition 07 2017 ...

Page 38: ...38 SIPROTEC 5 Overcurrent Protection Manual C53000 G5040 C017 8 Edition 07 2017 ...

Page 60: ...60 SIPROTEC 5 Overcurrent Protection Manual C53000 G5040 C017 8 Edition 07 2017 ...

Page 186: ...186 SIPROTEC 5 Overcurrent Protection Manual C53000 G5040 C017 8 Edition 07 2017 ...

Page 194: ...194 SIPROTEC 5 Overcurrent Protection Manual C53000 G5040 C017 8 Edition 07 2017 ...

Page 966: ...966 SIPROTEC 5 Overcurrent Protection Manual C53000 G5040 C017 8 Edition 07 2017 ...

Page 1072: ...1072 SIPROTEC 5 Overcurrent Protection Manual C53000 G5040 C017 8 Edition 07 2017 ...

Page 1236: ...1236 SIPROTEC 5 Overcurrent Protection Manual C53000 G5040 C017 8 Edition 07 2017 ...

Page 1306: ...1306 SIPROTEC 5 Overcurrent Protection Manual C53000 G5040 C017 8 Edition 07 2017 ...

Page 1370: ...1370 SIPROTEC 5 Overcurrent Protection Manual C53000 G5040 C017 8 Edition 07 2017 ...

Page 1404: ...1404 SIPROTEC 5 Overcurrent Protection Manual C53000 G5040 C017 8 Edition 07 2017 ...

Page 1576: ...1576 SIPROTEC 5 Overcurrent Protection Manual C53000 G5040 C017 8 Edition 07 2017 ...

Page 1614: ...1614 SIPROTEC 5 Overcurrent Protection Manual C53000 G5040 C017 8 Edition 07 2017 ...

Page 1634: ...1634 SIPROTEC 5 Overcurrent Protection Manual C53000 G5040 C017 8 Edition 07 2017 ...