3-31

January 24, 2017

Removal and Installation

CLG835H

Removal and installation of torque converter-gearbox system

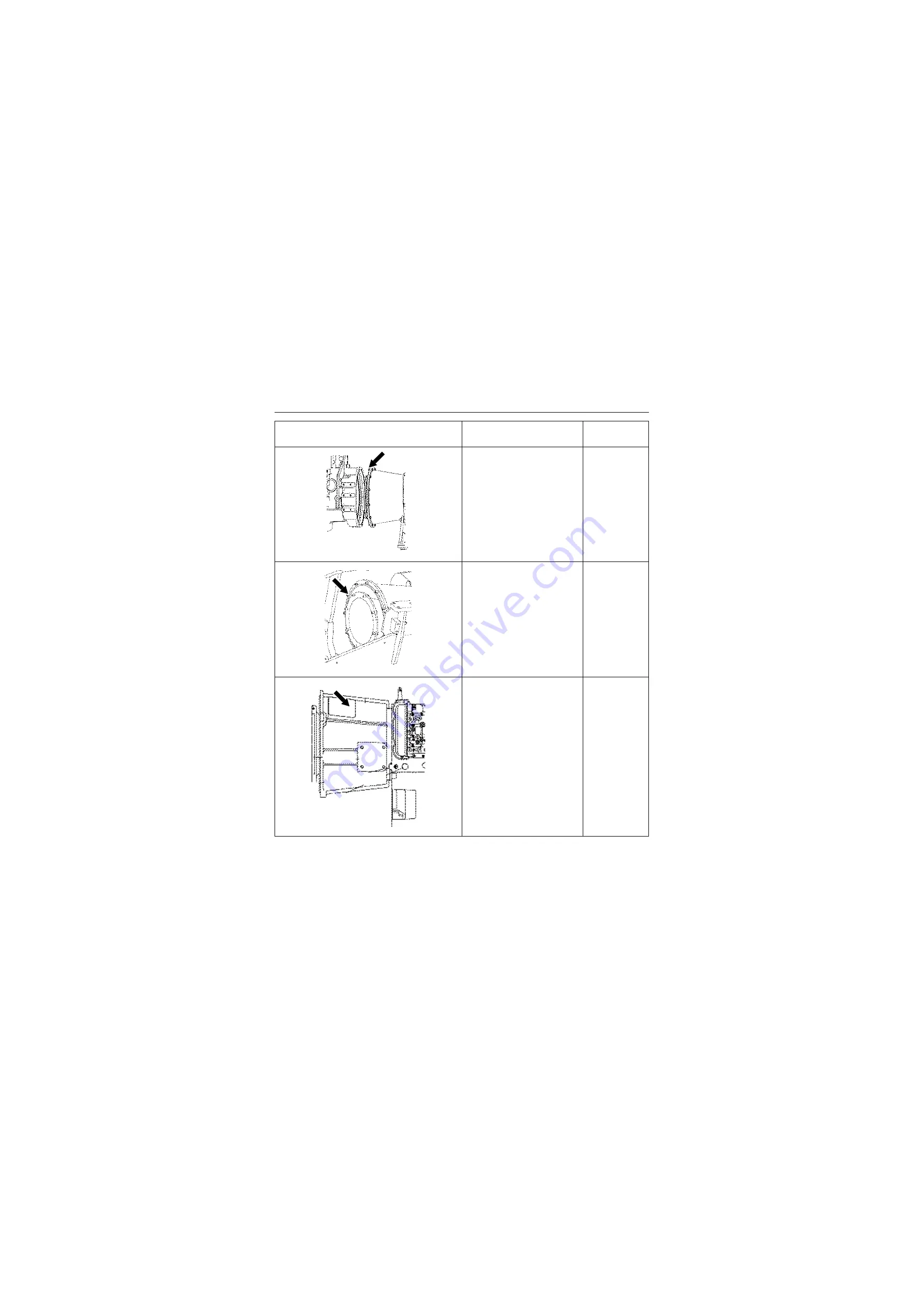

4. Move gear box assembly to

fit it with engine flywheel

housing, and install the bolts

and hard washer used for

tightening the torque con-

verter case to the engine

housing and then tighten

them. Tightening torque:

72±6Nm\ 53.1±4.4 lbf•ft.

16# socket,

pneumatic

impact wrench,

open-end 16#

fixed torque

spanner

5. Crank the engine flywheel

case to make the torque

converter align with mount-

ing threaded hole on the

engine flywheel, screw and

tighten the fastening bolts

and washer for attaching the

torque converter to the

engine flywheel by hand

with a torque of 60±5Nm\

44.25±3.7 lbf•ft

16# socket,

pneumatic

impact wrench,

open-end 16#

fixed torque

spanner

6. Install the mounting hole

cover plate on the gear box.

13# Wrench

Reference picture

Operation step

Tools required

(Remarks)

P18T00051

P18T00052

P18T00053

Summary of Contents for CLG835H

Page 2: ......

Page 4: ...Contents January 24 2017 CLG835H...

Page 6: ...1 2 General Information January 24 2017 CLG835H...

Page 38: ...1 34 Machine Inspection Table January 24 2017 CLG835H...

Page 156: ...3 2 Power Train System January 24 2017 CLG835H...

Page 214: ...3 2 Power Train System January 24 2017 CLG835H...

Page 272: ...3 60 Testing and adjustment January 24 2017 Power Train Test CLG835H...

Page 276: ...4 4 Hydraulic System January 24 2017 CLG835H...

Page 552: ...6 2 Driver s Cab System January 24 2017 CLG835H...

Page 608: ...7 2 Structure January 24 2017 CLG835H...

Page 662: ...8 4 Electrical System January 24 2017 CLG835H...

Page 677: ...8 19 January 24 2017 Structure Function Principle CLG835H Power System P18E00014...