3-43

January 24, 2017

Removal and Installation

CLG835H

Removal and installation of front axle assembly

Removal and installation of front axle assembly

Removal of front axle assembly

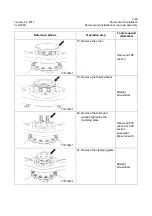

8. Install the tightening bolts

and washer of the middle

support bearing seat and

support plate, and tighten

them to 22494±18.44 lbf•ft.

24# socket, fixed

torque blower

gun or open-end

24# fixed torque

spanner

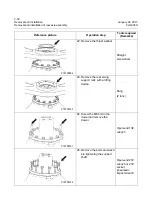

Reference picture

Operation step

Tools required

(Remarks)

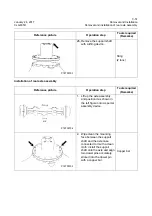

1. Stop the machine on a level

ground, put the work imple-

ment, bucket levelly, and pull

up the emergency parking

brake lever.

2. Turn off the engine, step on

the service brake pedal for

several times, so as to

release the pressures of

energy accumulator and

axle brake pipe.

3. Lift up the machine with a

lifting device, and support it

up with a supporting device

with 4 tires off the ground

Sling

(12 tons)

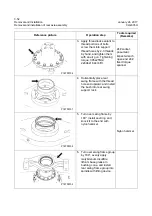

Reference picture

Operation step

Tools required

(Remarks)

P18T00079

Summary of Contents for CLG835H

Page 2: ......

Page 4: ...Contents January 24 2017 CLG835H...

Page 6: ...1 2 General Information January 24 2017 CLG835H...

Page 38: ...1 34 Machine Inspection Table January 24 2017 CLG835H...

Page 156: ...3 2 Power Train System January 24 2017 CLG835H...

Page 214: ...3 2 Power Train System January 24 2017 CLG835H...

Page 272: ...3 60 Testing and adjustment January 24 2017 Power Train Test CLG835H...

Page 276: ...4 4 Hydraulic System January 24 2017 CLG835H...

Page 552: ...6 2 Driver s Cab System January 24 2017 CLG835H...

Page 608: ...7 2 Structure January 24 2017 CLG835H...

Page 662: ...8 4 Electrical System January 24 2017 CLG835H...

Page 677: ...8 19 January 24 2017 Structure Function Principle CLG835H Power System P18E00014...