3-33

January 24, 2017

Removal and Installation

CLG835H

Removal and installation of torque converter-gearbox system

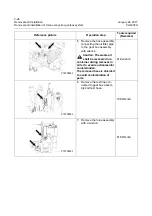

7. Screw and tighten the bolts

and washer for fastening the

gear box mount to the frame

with the torque of

2035±170Nm\

1500.8±125.38 lbf•ft.

46# wrench, 46#

socket,

pneumatic

impact wrench,

open-end 46#

fixed torque

spanner

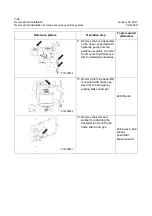

8. Attach the mounting end

flanges of drive shaft and

gear box to the rear output

flange of gear box, and

tighten the locknut to

132±10Nm\ 97.35±7.38

lbf•ft.

18# wrench or

open-end 18#

fixed torque

spanner

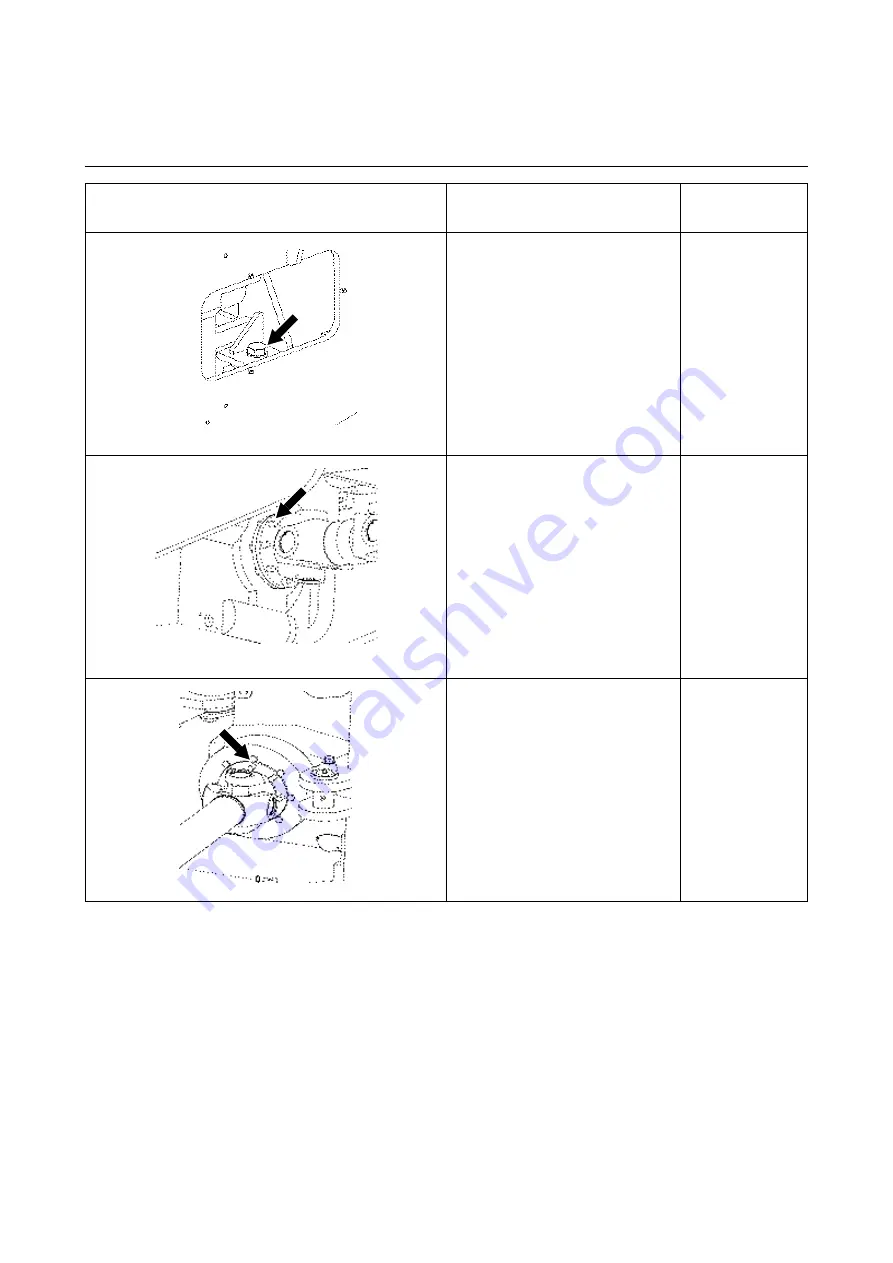

9. Attach the intermediate drive

shaft to front output flange of

gear box and tighten the

locknut to 200±15Nm\

147.5±11.06 lbf•ft.

21# wrench or

open-end 21#

fixed torque

spanner

Reference picture

Operation step

Tools required

(Remarks)

P18T00054

P18T00055

P18T00056

Summary of Contents for CLG835H

Page 2: ......

Page 4: ...Contents January 24 2017 CLG835H...

Page 6: ...1 2 General Information January 24 2017 CLG835H...

Page 38: ...1 34 Machine Inspection Table January 24 2017 CLG835H...

Page 156: ...3 2 Power Train System January 24 2017 CLG835H...

Page 214: ...3 2 Power Train System January 24 2017 CLG835H...

Page 272: ...3 60 Testing and adjustment January 24 2017 Power Train Test CLG835H...

Page 276: ...4 4 Hydraulic System January 24 2017 CLG835H...

Page 552: ...6 2 Driver s Cab System January 24 2017 CLG835H...

Page 608: ...7 2 Structure January 24 2017 CLG835H...

Page 662: ...8 4 Electrical System January 24 2017 CLG835H...

Page 677: ...8 19 January 24 2017 Structure Function Principle CLG835H Power System P18E00014...