3-53

January 24, 2017

Removal and Installation

CLG835H

Removal and installation of rear axle assembly

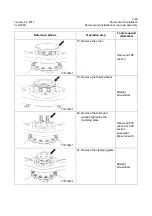

7. Install thrust washer and

pressing plate and align the

holes well.

8. Apply thread lock sealant to

thread portion of bolt, screw

bolts and hard washers into

the clamping plate thread

holes by 2-3 teeth by hand,

and drive them in

symmetrically with

pneumatic impact wrench

with the tightening torque of

305±25Nm\ 224.94±18.44

lbf•ft.

24# socket,

pneumatic

impact wrench,

open-end 24#

fixed torque

spanner

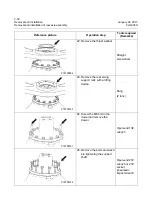

9. Put a thrust washer and

cover and align the holes

well.

10. Apply thread lock sealant to

thread of bolts, screw bolts

and hard washers into cover

thread holes by 2-3 teeth by

hand, and drive them in

symmetrically with

pneumatic impact wrench

with the tightening torque of

195±15Nm\ 143.81±11.06

lbf•ft.

21# socket,

pneumatic

impact wrench,

open-end 21#

fixed torque

spanner

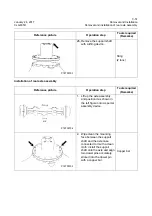

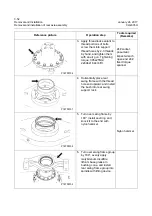

Reference picture

Operation step

Tools required

(Remarks)

P18T00110

P18T00111

P18T00112

P18T00113

Summary of Contents for CLG835H

Page 2: ......

Page 4: ...Contents January 24 2017 CLG835H...

Page 6: ...1 2 General Information January 24 2017 CLG835H...

Page 38: ...1 34 Machine Inspection Table January 24 2017 CLG835H...

Page 156: ...3 2 Power Train System January 24 2017 CLG835H...

Page 214: ...3 2 Power Train System January 24 2017 CLG835H...

Page 272: ...3 60 Testing and adjustment January 24 2017 Power Train Test CLG835H...

Page 276: ...4 4 Hydraulic System January 24 2017 CLG835H...

Page 552: ...6 2 Driver s Cab System January 24 2017 CLG835H...

Page 608: ...7 2 Structure January 24 2017 CLG835H...

Page 662: ...8 4 Electrical System January 24 2017 CLG835H...

Page 677: ...8 19 January 24 2017 Structure Function Principle CLG835H Power System P18E00014...