386

D90

PLUS

LINE DISTANCE PROTECTION SYSTEM – INSTRUCTION MANUAL

PROTECTION INPUTS AND OUTPUTS

CHAPTER 7: PROTECTION

The FlexLogic™ operand response time to the contact input change is equal to the

debounce time setting plus a maximum of one protection pass (depending on system

frequency if frequency tracking is enabled). If the change of state occurs just after a

protection pass, the recognition is delayed until the subsequent protection pass (that is, by

the entire duration of the protection pass). If the change occurs just prior to a protection

pass, the state is recognized immediately. Statistically, a delay of half the protection pass is

expected. Owing to the 0.25 ms scan rate, the time resolution for the input contact is less

than 1 ms.

For example, sixteen protection passes per cycle on a 60 Hz system correspond to a

protection pass every 1.04 ms. With a contact debounce time setting of 3.0 ms, the

FlexLogic™ operand assert time limits are: 3.0 + 0.0 = 3.0 ms and 3.0 + 1.04 = 4.04 ms.

These time limits depend on how soon the protection pass runs after the debouncing time.

Regardless of the contact debounce time setting, the contact input event is time-stamped

with a 1 ms accuracy using the time of the first scan corresponding to the new state.

Therefore, the time stamp reflects a change in the DC voltage across the contact input

terminals that was not accidental as it was subsequently validated using the debounce

timer. Keep in mind that the associated FlexLogic™ operand is asserted/de-asserted later,

after validating the change. The debounce algorithm is symmetrical: the same procedure

and debounce time are used to filter the OFF-ON and ON-OFF transitions.

The active impedance feature controls the input impedance presented to the system

according to the current state of the input. When the contact input circuitry initially detects

a voltage increase, it will draw 10 mA of current. If the state change is due to a transient

coupled through the stray capacitance of the field wiring, then the high current sink will

charge the capacitance causing the transient to rapidly decay. If voltage increase is due to

a state change of the field contact, then the increased current will have no impact on the

input voltage, and the state change will be validated. Once the input has been declared to

be on, the input circuitry will reduce the current drawn to 1 mA to minimize the power

dissipated by the input.

NOTE

NOTE:

The contact input update time is 1 ms. However, depending on where the contact input

status change is triggered within a one millisecond window, the worst-case contact input

recognition time will be 2 ms.

CAUTION

CAUTION:

If a D90

Plus

unit with firmware revision 1.60 is changed to firmware 1.50 or lower, then

the contact input and output calibration values will be lost.

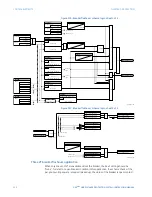

Contact input and output default assignment

When a new settings file is created, the available contacts are automatically assigned to

the protection or automation functions according to the following convention.

•

First I/O module

→

protection.

•

All subsequent I/O modules

→

automation.

For example, if a D90

Plus

is configured with contact input/output cards in slots E, F, and G,

then the inputs and outputs associated with slot E are assigned to protection and the

inputs and outputs associated with slots F and G are assigned to automation.

These default assignments may be changed to match the requirements of the application.

This is done by right-clicking on the setting filename and choosing the menu

Manage

Settings File > I/O Assignments

menu item. The following window is displayed.