February 2013

3-24

ColorQube® 9303 Family

IQ 5

Image Quality

IQ 5 Jagged or Blurry Lines or Text RAP

Use this RAP to troubleshoot the following defects:

•

Jagged lines in the cross process direction

•

Jagged text in the cross process direction

•

Blurry text

•

Irregularly spaced text

Ensure

IQ 1

Image Quality Entry RAP is performed before starting this RAP.

Initial Actions

WARNING

Ensure that the electricity to the machine is switched off while performing tasks that do

not need electricity. Refer to

GP 14

. Disconnect the power cord. Electricity can cause

death or injury. Moving parts can cause injury.

WARNING

Take care during this procedure. The stripper blade is very sharp and can cause injury.

WARNING

Do not clean the stripper blade. The stripper blade is very sharp and can cause injury. If

the stripper blade is dirty a new blade must be installed.

WARNING

Take care during this procedure. Sharp edges may be present that can cause injury.

CAUTION

Use care when moving the marking unit into the service position when hot. Ink can spill from

the ink reservoir located at the back of the unit if opened with too much force. Cross-colour ink

contamination could also occur.

CAUTION

Do not touch the exposed face of the printheads. Surface contamination or minor damage can

easily make the printhead unusable.

•

Check that the printheads are securely attached to the carriage. Run

dC967

Printhead to

Drum Spacing. Perform

ADJ 91.1

Printhead Attachment Check.

•

Check that the printhead carriages are fully docked against the drum frame. If not, check

the wiring that runs along the umbilicals. Failure to properly route the upper or lower car-

riage wiring may lead to jagged or blurry lines or text.

Procedure

1.

TP 1

Initial Test Print Pages and

TP 16

Stitch Identification Test Pages. Check for

the following defects:

•

Alignment errors,

Figure 1

and

Figure 2

. Dot placement errors spanning all colours in

one or more of the printhead stitch zones. If observed, go to the

Y-Stitch, Printhead

Roll and Drum Runout Checkout

.

•

Misdirected or weak jets,

Figure 3

. If observed, go to the

Weak Jets with Y-Dot Error

Checkout

.

•

Weak intensity and poor Y-dot placement in all colours and all jets of a single print-

head,

Figure 4

. A pale band across the whole width of a head with misplacement in

the process direction. If observed, go to the

Weak Intensity and Y-Dot Error in All

Colours Across a Printhead

.

•

Y-dot placement defects in the process direction with acceptable jet intensity,

Figure

5

. A jagged edge in the process direction on lines and colour bands. If observed, go

to the

Y-Dot Error Checkout

.

•

Jagged text,

Figure 6

. Pixel position may be incorrect in the process direction. If

observed, go to the

Blurry / Jagged Text Defect Checkout

.

2.

If the defect does not match any of the above, re-define the image quality defect. Refer to

IQ 1

Image Quality Entry RAP.

Y-Stitch, Printhead Roll and Drum Runout Checkout

Procedure

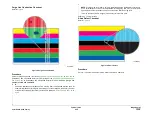

Evaluate

TP 16

Stitch Identification Test Page,

Figure 1

and

Figure 2

. The severity of the

stitch defect varies in the process direction,

Figure 2

.

Y

N

Perform

dC971

Head to Head Alignment Adjustment up to three times. Print

TP 16

Stitch

Identification Test Pages. Refer to

IQS 3

Y-Dot Position. The severity of the alignment

defect is within specification.

Y

N

Perform

dC914

Head to Head Alignment Test and check for obstructions that block

head alignment motion. The head alignment motion is free from obstructions.

Y

N

Remove obstructions and check printhead stitch and roll motor operation, refer

to:

•

91-504-00, 91-505-00

Printhead Stitch Motor Over Current RAP.

•

91-506-00 to 91-509-00

Roll Motor Over Current RAP.

Check that the printheads are securely attached to the carriage. The printheads

are securely attached.

Y

N

Perform

ADJ 91.1

Printhead Attachment Check.

Perform

dC971

Head to Head Alignment Adjustment. Print

TP 16

Stitch Identification

Test Pages.

if the severity of the alignment defect exceeds specification, refer to

IQS 3

Y-Dot

Position. Perform the following:

•

Check for obstructions that block carriage and printhead motion.

•

Clean the IOD, refer to

GP 27

Cleaning Procedure.

•

Clean the drum, refer to

GP 27

Cleaning Procedure.

Perform

SCP 5

Final Actions.

NOTE: Before printing TP 23, ensure that A4 or 8.5 x 11 inch plain paper is loaded long edge

feed into tray 4. Use the best quality media available. Do not use hole punched paper.

Perform

dC977

Drum Runout Calibration. Print

TP 23

Drum Runout and Y-stitch Test Pages.

The test pages are good.

Summary of Contents for ColorQube 9303 Series

Page 1: ...Xerox ColorQube 9303 Family Service Manual 708P90290 February 2013...

Page 4: ...February 2013 ii ColorQube 9303 Family Introduction...

Page 18: ...February 2013 1 2 ColorQube 9303 Family Service Call Procedures...

Page 92: ...February 2013 2 68 ColorQube 9303 Family 05F Status Indicator RAPs...

Page 104: ...February 2013 2 80 ColorQube 9303 Family 12 701 00 65 Status Indicator RAPs...

Page 200: ...February 2013 2 176 ColorQube 9303 Family 12N 171 Status Indicator RAPs...

Page 292: ...February 2013 2 268 ColorQube 9303 Family 16D Status Indicator RAPs...

Page 320: ...February 2013 2 296 ColorQube 9303 Family 42 504 00 42 505 00 Status Indicator RAPs...

Page 500: ...February 2013 2 476 ColorQube 9303 Family 94B Status Indicator RAPs...

Page 648: ...February 2013 3 2 ColorQube 9303 Family Image Quality...

Page 653: ...February 2013 3 7 ColorQube 9303 Family IQ 1 Image Quality Figure 1 IQ defects 1...

Page 654: ...February 2013 3 8 ColorQube 9303 Family IQ 1 Image Quality Figure 2 IQ defects 2...

Page 655: ...February 2013 3 9 ColorQube 9303 Family IQ 1 Image Quality Figure 3 IQ defects 3...

Page 656: ...February 2013 3 10 ColorQube 9303 Family IQ 1 Image Quality Figure 4 IQ defects 4...

Page 657: ...February 2013 3 11 ColorQube 9303 Family IQ 1 Image Quality Figure 5 IQ defects 5...

Page 658: ...February 2013 3 12 ColorQube 9303 Family IQ 1 Image Quality Figure 6 IQ defects 6...

Page 660: ...February 2013 3 14 ColorQube 9303 Family IQ 1 Image Quality Figure 9 IQ defects 9...

Page 661: ...February 2013 3 15 ColorQube 9303 Family IQ 1 Image Quality Figure 10 IQ defects 10...

Page 662: ...February 2013 3 16 ColorQube 9303 Family IQ 1 Image Quality Figure 11 IQ defects 11...

Page 663: ...February 2013 3 17 ColorQube 9303 Family IQ 1 Image Quality Figure 12 IQ defects 12...

Page 664: ...February 2013 3 18 ColorQube 9303 Family IQ 1 Image Quality Figure 13 IQ defects 13...

Page 728: ...February 2013 3 82 ColorQube 9303 Family IQ 29 IQ 30 Image Quality...

Page 736: ...February 2013 3 90 ColorQube 9303 Family TP 15 Image Quality Figure 2 Media path test pages...

Page 758: ...February 2013 3 112 ColorQube 9303 Family IQS 7 IQS 8 Image Quality...

Page 778: ...February 2013 4 20 ColorQube 9303 Family REP 1 9 Repairs Adjustments...

Page 794: ...February 2013 4 36 ColorQube 9303 Family REP 3 10 Repairs Adjustments...

Page 1144: ...February 2013 4 386 ColorQube 9303 Family REP 94 1 Repairs Adjustments...

Page 1176: ...February 2013 4 418 ColorQube 9303 Family ADJ 62 3 ADJ 62 4 Repairs Adjustments...

Page 1182: ...February 2013 4 424 ColorQube 9303 Family ADJ 75 3 Repairs Adjustments...

Page 1184: ...February 2013 4 426 ColorQube 9303 Family ADJ 82 1 Repairs Adjustments...

Page 1186: ...February 2013 4 428 ColorQube 9303 Family ADJ 91 1 Repairs Adjustments...

Page 1552: ...February 2013 6 260 ColorQube 9303 Family dC140 General Procedures Information...

Page 1576: ...February 2013 6 284 ColorQube 9303 Family dC640 General Procedures Information...

Page 1578: ...February 2013 6 286 ColorQube 9303 Family dC708 dC715 General Procedures Information...

Page 1600: ...February 2013 7 2 ColorQube 9303 Family Wiring Data...

Page 1696: ...February 2013 8 2 ColorQube 9303 Family Principles of Operation...

Page 1808: ...February 2013 8 114 ColorQube 9303 Family Principles of Operation...

Page 1809: ...XEROX EUROPE...

Page 1810: ...XEROX EUROPE...

Page 1811: ...XEROX EUROPE...

Page 1812: ...XEROX EUROPE...