Actual signals and parameters

200

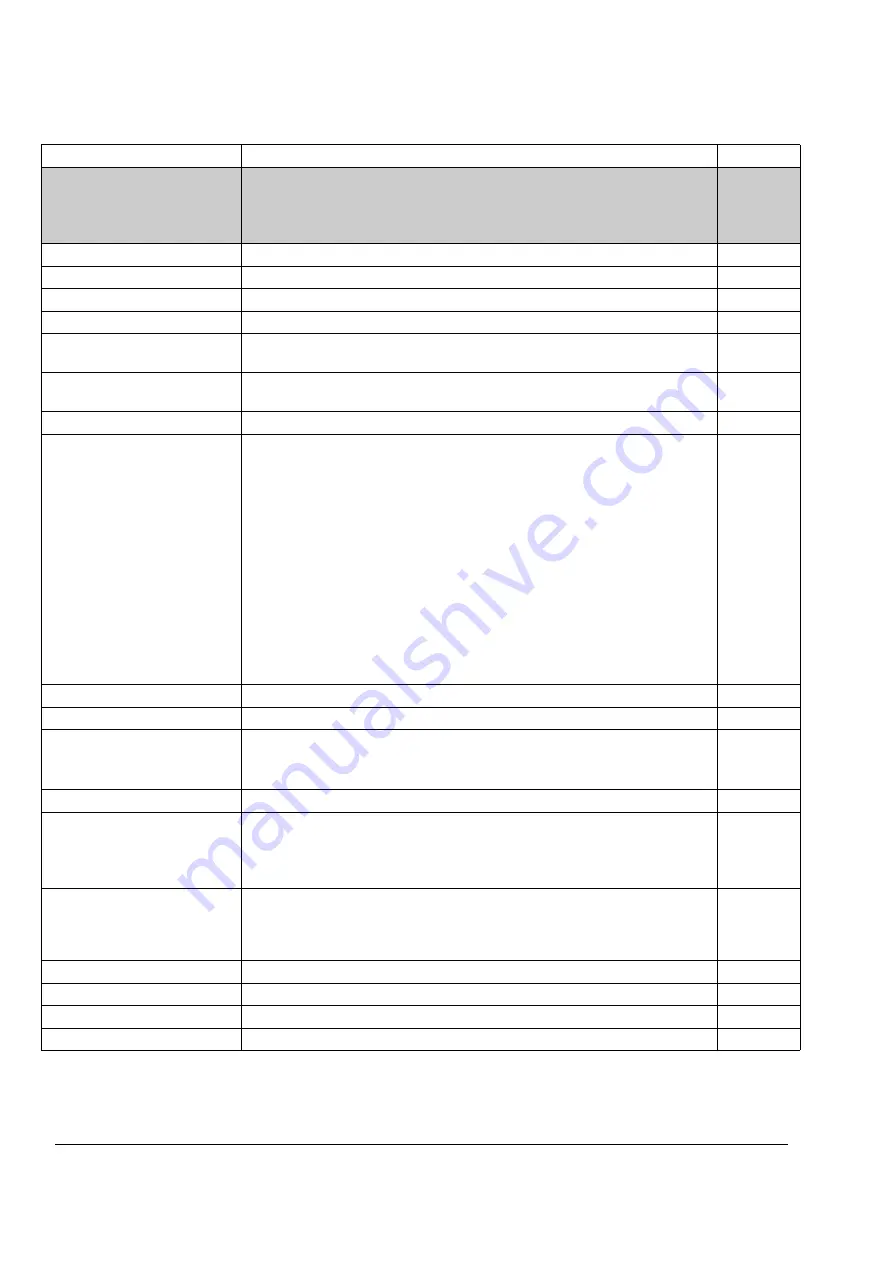

50 ENCODER MODULE

Encoder connection. Visible only when a pulse encoder module (optional) is

installed and activated with parameter

.

The settings will remain the same even though the application macro is

changed.

50.01

PULSE NR

States the number of encoder pulses per one revolution.

0 … 29999 ppr

Pulse number in pulses per round (ppr)

0 … 29999

50.02

SPEED MEAS MODE Defines how the encoder pulses are calculated.

A

-

-

B DIR

Channel A: positive edges calculated for speed. Channel B: direction.

0

A

-

-

-

Channel A: positive and negative edges calculated for speed. Channel B: not

used.

1

A

-

-

-

B DIR

Channel A: positive and negative edges are calculated for speed. Channel B:

direction.

2

A

-

-

-

B

-

-

-

All edges of the signals are calculated.

3

50.03

ENCODER FAULT

Defines the operation of the drive if a failure is detected in communication

between the pulse encoder and the pulse encoder interface module, or

between the module and the drive. Encoder supervision function activates if

either of the following conditions is valid:

-The difference between the estimated and measured speed is greater than

20% of the motor nominal speed.

- No pulses are received from the encoder within the defined time (see

parameter

) and the drive is simultaneously at the current or torque limit.

When the torque is zero or low, the shaft may not move and no pulses are

detected. This means that at low torque/current the missing-pulse-supervision

is not possible. Therefore there must be conditional torque or current limit in

the pulse supervision. Now the limit is the maximum torque/current, because

then the shaft is expected to move at least a little bit and at least some encoder

pulses are detected.

WARNING

The drive generates a warning indication.

0

FAULT

The drive trips on a fault, gives a fault indication and stops the motor.

65535

50.04

ENCODER DELAY

Defines the time delay for the encoder supervision function at start (See

parameter

Note

: It the delay is set to 0 ms, encoder supervision at start is disabled.

0 … 50000 ms

Time delay

0 … 50000

50.05

ENCODER DDCS CH Defines the fibre optic channel of the control board from which the drive

program reads the signals coming from the pulse encoder interface module.

The setting is valid only if the module is connected to the drive via the DDCS

link (that is not to the option slot of the drive).

CH 1

Signals via channel 1 (CH1). The pulse encoder interface module must be

connected to CH1 instead of CH2 in applications where CH2 is reserved by a

Master station (For example, a Master/Follower application). See also

parameter

1

CH 2

Signals via channel 2 (CH2). Can be used in most cases.

2

50.06

SPEED FB SEL

Defines the speed feedback value used in control.

INTERNAL

Calculated speed estimate

65535

ENCODER

Actual speed measured with an encoder

0

Index

Name/Selection

Description

FbEq

Summary of Contents for ACS 800 Series

Page 1: ...ACS800 Firmware Manual Crane Control Program N697 ...

Page 4: ......

Page 26: ...Start up and control through the I O interface 26 ...

Page 36: ...Quick start up guide 36 ...

Page 52: ...Control panel 52 ...

Page 105: ...Program features 105 Figure Control diagram for Shaft synchronisation executed in 20 ms ...

Page 128: ...Program features 128 ...

Page 150: ...Application macros control location EXT1 EXT2 150 ...

Page 228: ...Actual signals and parameters 228 ...

Page 299: ...Adaptive Programming examples for crane control 299 ...

Page 305: ...Adaptive Programming examples for crane control 305 ...

Page 318: ...Analogue Extension Module 318 ...

Page 332: ...Additional data actual signals and parameters 332 ...

Page 334: ...DriveWindow 334 ...

Page 335: ...Control block diagrams 335 Control block diagrams ...

Page 336: ...Control block diagrams 336 ...

Page 337: ...Control block diagrams 337 ...

Page 338: ...Control block diagrams 338 ...

Page 340: ...www abb com drives www abb com drivespartners Contact us 3AFE68775230 Rev E EN 2012 09 25 ...