Installation and Operation Guide

ED-DT318B

Drive Train Systems with Traction Control, Inverter/Controller, and Motor with 2 Speed Transmission

BC353060341319en-000101

Revision D

© Danfoss | November 2020 | 150

Classified as Business

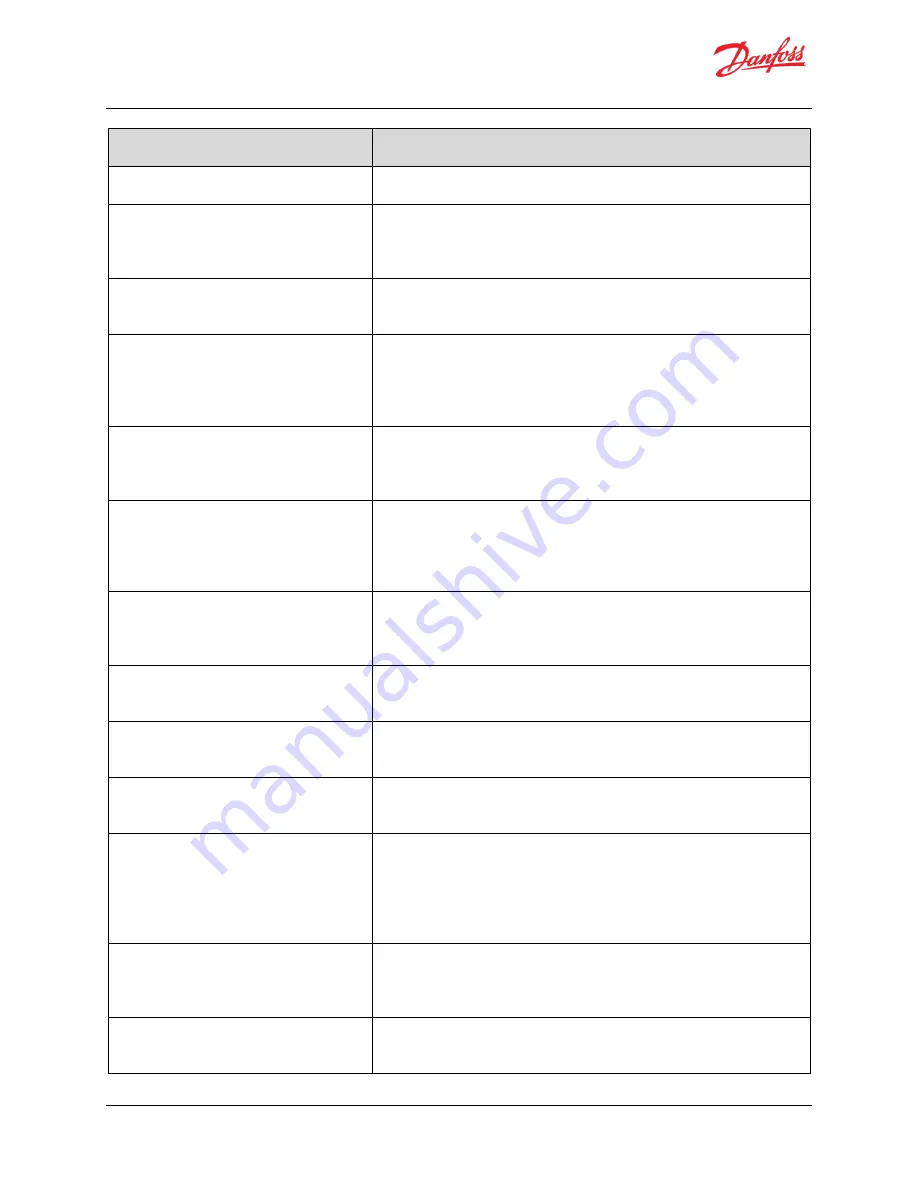

Entries

Description

Bad rotor temperature occurred

The rotor temperature sensor is suspect.

Inverter Temp Shutdown

Rotor Temp Shutdown

Stator Temp Shutdown

These events mark when temperatures exceeded limits, causing

the power switches of the inverter to shut down.

Over Positive Phase Advance ONCE

Under Negative Phase Advance ONCE

These events mark when the controller has encountered the phase

limits of the motor.

Position signal is bad

Position signal has come good

Position error is too large

Apparent rotor movement occurred

These events mark a problem or the resolution of a problem with

the position sensor signals. Either a cable was removed or the

position offset is suspect.

Mechanical revolution count occurred

The user configurable number of motor revolutions has occurred.

This entry will be made each time that counter counts this number

of revolutions.

CANbus watchdog occurred

CANbus commands ceased. This is sometimes seen benignly

because the vehicle controller is powered off and is no longer

communicating, but the motor controller has not yet been

powered off.

Torque matching problem

The controller found that it was unable to control the motor to the

desired torque. If this occurs regularly, this could be because the

motor has partially demagnetized.

Back EMF saturated high

Back EMF saturated low

The dynamic motor tuning control could not find the motor’s Back

EMF. Indicates that the wrong motor is connected.

Low Forced Voltage Control Occurred

The controller went into forced voltage control because of

dangerous low voltage conditions.

Disconnected Battery Event Occurred

The controller detected conditions that indicated no power supply

connection. This condition often results in forced voltage control.

Noisy position < 1 Hz

Noisy position < 150 Hz

Noisy position < 250 Hz

Noisy position < 350 Hz

Noisy position > 350 Hz

Electrical noise occurred on the position signals. This is a

potentially dangerous condition because it could cause motor

miscommutation if this rate is greater than 150 Hz.

Regen Switch closed

Regen Switch open

Indicates the state of the 7th power switch in the inverter, called

the Regen Switch. It isolates the inverter when high voltage or high

regeneration current occurs.

Stalled OFF

Stalled ON

These events mark when the controller severely limited torque

while the motor could not spin.

Содержание ED-DT318B

Страница 185: ......