Installation and Operation Guide

ED-DT318B

Drive Train Systems with Traction Control, Inverter/Controller, and Motor with 2 Speed Transmission

BC353060341319en-000101

Revision D

© Danfoss | November 2020 | 137

Classified as Business

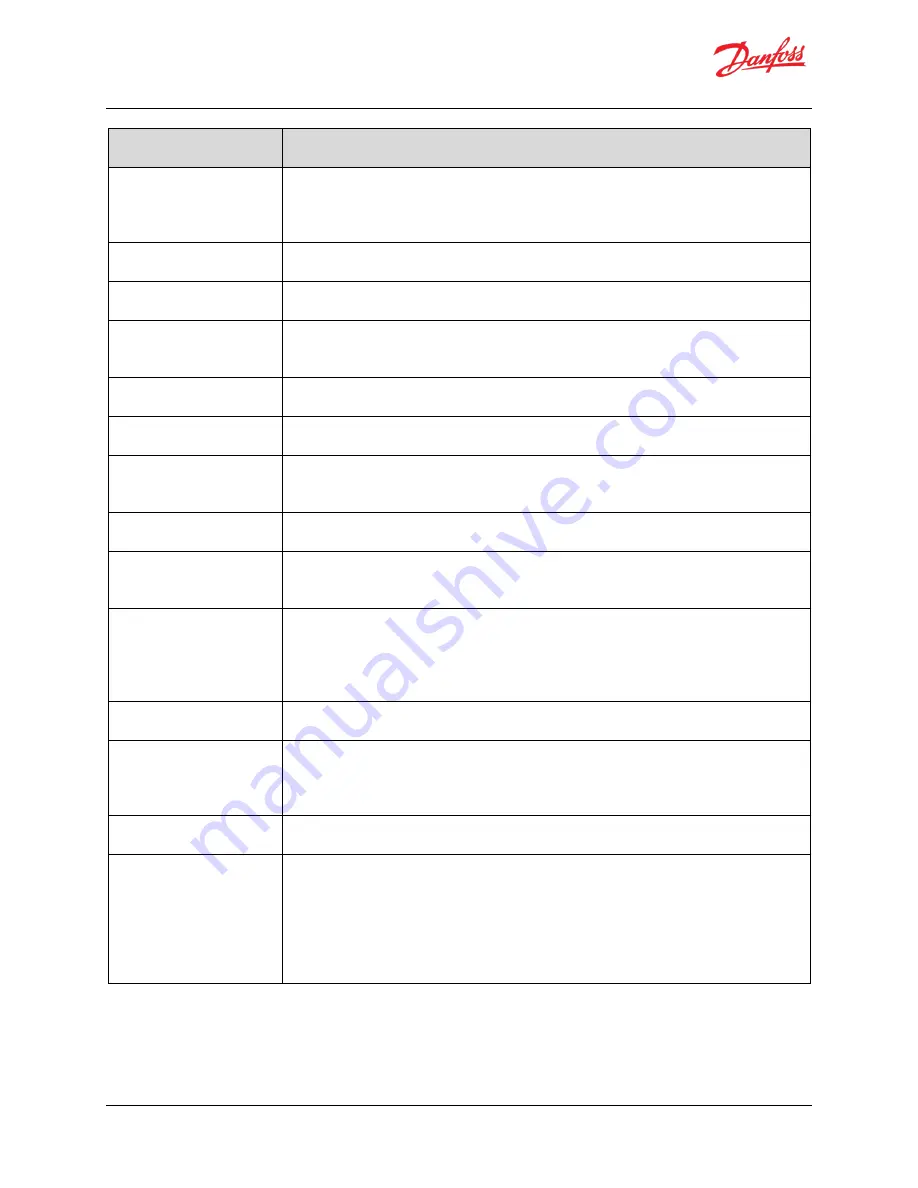

Column Label

Description

Motor Direction

The direction of the motor. 1 is “Forward” and –1 is “Reverse.” This value

multiplied by either Speed or FilteredSpeed provides signed speed values like

those available through CANbus.

Stator Temp (ºC)

The measured temperature of the stator of the motor in degrees Celsius.

Rotor Temp (ºC)

The measured temperature of the rotor of the motor in degrees Celsius.

Inverter Temp (ºC)

The measured temperature of the controller at its cooling block in degrees

Celsius.

Bus Voltage (V)

The measured bus voltage in volts.

Bus Current (A)

The measured bus current in amperes.

Elec Power (W)

The electrical power in watts as calculated by the controller from the bus voltage

and current.

Leg Current (A)

The measured envelope of the current motor’s phase legs.

Acceleration (RPM/sec)

The calculated rate of acceleration of the Danfoss Power Solutions motor. The

maximum acceleration rate can be controlled by the .

Stall Percentage

The stall percentage value counts up from 0 to 100 as the motor approaches stall

conditions. When the count reaches 100, a stall condition is detected, and the

motor will limit torque to 10% of rated output for 30 seconds. For more

information on stall conditions, please refer to

Section 5.3.3

RevCounter

Positive integer number of motor revolutions since the inverter was power up

AngularDistance

Total angular distance the motor has traveled since the inverter was powered up

(1 count = 3.75°). Travel in the Forward direction is positive. Travel in the Reverse

direction is negative.

Desired Direction

The requested direction of the motor. A 1 is “Forward” and –1 is “Reverse.”

Requested Torque

(Nm)

This is the amount of torque requested by the user, in Newton meters. The values

reported in this column come directly from the received CAN torque commands.

This is useful in debugging because it allows the user to check whether the CAN

commands contained the correct values and were received by the controller. In

contrast, the

Desired Torque

column reports the torque that the controller intends

to produce, after applying safeties and limits to the requested torque.

Содержание ED-DT318B

Страница 185: ......