107017-11 EN FR26 GLO 0999 Printed in Germany

3

FIG 3. QUADRATIC TOTAL CURRENT LIMIT

FS

R

S

1

Figure 3. displays the maximal recommended

external temperature versus the total load of all the

safety module contacts. To use this curve, do the

following:

(1) Square the current in each contact branch,

then sum all the results to obtain the vertical

axis value.

(2) Depending on what current is inside the safety

module contacts (AC or DC), follow the

horizontal line from the obtained value and

note intersection of the appropriate curve.

(3) Follow the intersection point down to determine

the maximal recommended external

temperature.

(Ex:

∑

Ι

2

= 200 A

2

, AC current inside safety

contacts, then T = 22

°

C (72

°

F).

If the module is located in a higher temperature

environment, the lifetime of the electronic

components may be reduced. Ventilation of the

cabinet may be required.

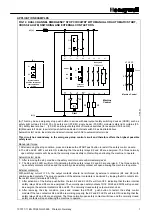

MECHANICAL INSTALLATION

The FF-SRS5935 must be installed inside a NEMA

3 (IEC IP54) rating enclosure or better. The module

can be clipped easily onto a 45mm width DIN rail

(see figures 4 and 5 for installation and removal).

Specific features of this product include removable

block terminals. This feature provides easy access

to wiring during installation and reduces machine

downtime during maintenance.

FIG 4. MOUNTING DIMENSIONS (for reference

only)

Rail

c

b

a

FSRS2

FIG 5. INSTALLATION DIAGRAM

FSRD3

FIG 6. REMOVABLE TERMINAL BLOCKS

Removable Terminal

Block

FS

RS

4

CONTROL RELIABILITY

“Control Reliability” means that “the device, system

or interface shall be designed, constructed and

installed such that a single component failure within

the device, interface or system shall not prevent

normal stopping action from taking place but shall

prevent a successive machine cycle.” (ANSI

B11.19-1990, 5.5)

OSHA 29 CFR 1910.217 states that “the control

system shall be constructed so that a failure within

the system does not prevent the normal stopping

action from being applied to the press when

required, but does prevent initiation of a successive

stroke until the failure is corrected. The failure shall

be detectable by a simple test, or indicated by the

control system.”

Honeywell has developed new patented self-

checking techniques which combine reliability with

safety. The FF-SR Series safety control modules

function with dual channel redundancy and positive

self-checking monitoring. This means that a faulty

component in our system will make the safety

control modules fail in a safe mode.

This design meets the highest requirements

(Category 4 as described in the EN 954 European

norm). Category 4 safety control modules are

designed and manufactured in such a way that a

single breakdown or an accumulation of failures

does not lead to the loss of the safety function

when a dangerous situation arises. The safety

function is maintained on a permanent basis.

a Width: 45 mm 1.77 in.

b Height: 74 mm 2.91 in.

c Depth: 121 mm 4.76 in.

32 50 68 86 104 122 140 T(

°

F)

Summary of Contents for SYA14 Series

Page 2: ...2 107031 23 EN FR26 GLO 1199 Printed in France This page has been left intentionally blank ...

Page 6: ...6 107031 23 EN FR26 GLO 1199 Printed in France This page has been left intentionally blank ...

Page 26: ...26 107031 23 EN FR26 GLO 1199 Printed in France This page has been left intentionally blank ...

Page 62: ...62 107031 23 EN FR26 GLO 1199 Printed in France This page has been left intentionally blank ...

Page 70: ...70 107031 23 EN FR26 GLO 1199 Printed in France This page has been left intentionally blank ...

Page 76: ...76 107031 23 EN FR26 GLO 1199 Printed in France This page has been left intentionally blank ...

Page 78: ...78 107031 23 EN FR26 GLO 1199 Printed in France This page has been left intentionally blank ...

Page 79: ...107031 23 EN FR26 GLO 1199 Printed in France 79 8 CE Declaration of Conformity ...

Page 80: ...80 107031 23 EN FR26 GLO 1199 Printed in France This page has been left intentionally blank ...

Page 84: ......

Page 158: ......

Page 160: ......

Page 161: ...For application help call 1 800 537 6945 Honeywell MICRO SWITCH Sensing and Control 80 ...

Page 165: ...3 107022 14 EN FR26 GLO 0100 Printed in Germany This page has been left intentionally blank ...

Page 201: ...39 107022 14 EN FR26 GLO 0100 Printed in Germany This page has been left intentionally blank ...

Page 205: ...43 107022 14 EN FR26 GLO 0100 Printed in Germany This page has been left intentionally blank ...

Page 207: ...45 107022 14 EN FR26 GLO 0100 Printed in Germany This page has been left intentionally blank ...

Page 208: ...107022 14 EN FR26 GLO 0100 Printed in Germany 46 9 Declaration of Conformity ...

Page 219: ...11 107006 11 EN FR26 GLO 0300 Printed in Germany This page has been left intentionally blank ...

Page 229: ...21 107006 11 EN FR26 GLO 0300 Printed in Germany This page has been left intentionally blank ...

Page 257: ...49 107006 11 EN FR26 GLO 0300 Printed in Germany This page has been left intentionally blank ...

Page 260: ...107006 11 EN FR26 GLO 0300 Printed in Germany 52 9 3 Declaration of conformity ...

Page 340: ...Safety Perimeter Guarding Installation Manual FF SPS4 Series Safety Perimeter Guarding ...

Page 536: ...2 107004 15 EN FR26 ROW 0899 Printed in France This page has been left intentionally blank ...

Page 538: ...4 107004 15 EN FR26 ROW 0899 Printed in France This page has been left intentionally blank ...

Page 542: ...107004 15 EN FR26 ROW 0899 Printed in France 8 This page has been left intentionally blank ...

Page 620: ...86 107004 15 EN FR26 ROW 0899 Printed in France This page has been left intentionally blank ...

Page 624: ...90 107004 15 EN FR26 ROW 0899 Printed in France This page has been left intentionally blank ...

Page 626: ...92 107004 15 EN FR26 ROW 0899 Printed in France This page has been left intentionally blank ...

Page 627: ...107004 15 EN FR26 ROW 0899 Printed in France 93 8 CE Declaration of Conformity ...

Page 628: ...94 107004 15 EN FR26 ROW 0899 Printed in France This page has been left intentionally blank ...