107017-11 EN FR26 GLO 0999 Printed in Germany

7

APPLICATION EXAMPLES

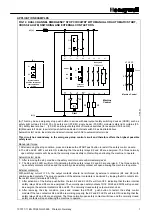

FIG 12. DUAL CHANNEL EMERGENCY STOP CIRCUITRY WITH MANUAL OR AUTOMATIC START,

CROSS-FAULT MONITORING AND EXTERNAL CONTACTORS.

A2

(-)

A1

(+)

S

11

S

12

S

22

S21

PE

S

33

S

34

13

23

33

41

Honeywell

FF-SRS5935

14

24

34

42

Power

K2

K3

S1

S2

Internal

Switches

(A)

Fuse

Machine

Control

L1 (+)

N (-)

Start

Off

K4

K5

K4

K5

Machine Control

K4

K5

Fuses

L2 L3

L1

(B)

S1

S2

Internal switch

position for manual

start operation

mode

(B)

FSRS10

(A) This may be an emergency stop push button in series with dual output safety switching devices (OSSD) such as

safety light curtains (FF-SB, FF-LS), safety mat (FF-SM), single beam (FF-SPS), modular safety light curtains (FF-

SC), safety laser scanner (FF-SE), dual output safety limit or interlock switches (for example: CLS and GK).

(B) Manual start mode: Insert start push-button and select internal switch S2 as illustrated above

Automatic start mode: Insert shunt and select internal switch S2 to automatic start mode

This circuit has redundancy in the emergency-stop control circuit and therefore offers the highest possible

safety level.

Manual start mode

1. After removing the stop condition, press and release the START push button to restart the safety control module.

2. The K2 and K3 LED’s will turn ON indicating that the safety relays K2 and K3 are energized. The three normally

open safety contacts will close and the normally closed safety contact will open allowing the machine to operate.

Automatic start mode

1. After removing the stop condition, the safety control module will immediately reset.

2. The K2 and K3 LED’s will turn ON indicating that the safety relays K2 and K3 are energized. The three normally

open safety contacts will close and the normally closed safety contact will open allowing the machine to operate.

External contactors:

With switching current >10 A, the output contacts should be reinforced by external contactors (K4 and K5) with

positive-guided contacts. The proper operation of the external contactors is monitored by looping the NC contacts into

the restart circuit (terminals S33-S34).

1. After activation of the E-stop push button, the two K2 and K3 LED’s will turn OFF, indicating that the two internal

safety relays K2 and K3 are de-energized. The normally open safety outputs 13/14, 23/24 and 33/34 will open and

de-energize the external contactors K4 and K5. The normally closed safety output will also close.

2. After removing the stop condition, press and release the START push button to restart the safety control

module.If the two contactors K4 and K5 are working properly, the K2 and K3 LED’s will turn ON indicating that the

safety relays K2 and K3 are energized. The three normally open safety contacts will close and the normally closed

safety contacts will open allowing the machine to operate.

Summary of Contents for SYA14 Series

Page 2: ...2 107031 23 EN FR26 GLO 1199 Printed in France This page has been left intentionally blank ...

Page 6: ...6 107031 23 EN FR26 GLO 1199 Printed in France This page has been left intentionally blank ...

Page 26: ...26 107031 23 EN FR26 GLO 1199 Printed in France This page has been left intentionally blank ...

Page 62: ...62 107031 23 EN FR26 GLO 1199 Printed in France This page has been left intentionally blank ...

Page 70: ...70 107031 23 EN FR26 GLO 1199 Printed in France This page has been left intentionally blank ...

Page 76: ...76 107031 23 EN FR26 GLO 1199 Printed in France This page has been left intentionally blank ...

Page 78: ...78 107031 23 EN FR26 GLO 1199 Printed in France This page has been left intentionally blank ...

Page 79: ...107031 23 EN FR26 GLO 1199 Printed in France 79 8 CE Declaration of Conformity ...

Page 80: ...80 107031 23 EN FR26 GLO 1199 Printed in France This page has been left intentionally blank ...

Page 84: ......

Page 158: ......

Page 160: ......

Page 161: ...For application help call 1 800 537 6945 Honeywell MICRO SWITCH Sensing and Control 80 ...

Page 165: ...3 107022 14 EN FR26 GLO 0100 Printed in Germany This page has been left intentionally blank ...

Page 201: ...39 107022 14 EN FR26 GLO 0100 Printed in Germany This page has been left intentionally blank ...

Page 205: ...43 107022 14 EN FR26 GLO 0100 Printed in Germany This page has been left intentionally blank ...

Page 207: ...45 107022 14 EN FR26 GLO 0100 Printed in Germany This page has been left intentionally blank ...

Page 208: ...107022 14 EN FR26 GLO 0100 Printed in Germany 46 9 Declaration of Conformity ...

Page 219: ...11 107006 11 EN FR26 GLO 0300 Printed in Germany This page has been left intentionally blank ...

Page 229: ...21 107006 11 EN FR26 GLO 0300 Printed in Germany This page has been left intentionally blank ...

Page 257: ...49 107006 11 EN FR26 GLO 0300 Printed in Germany This page has been left intentionally blank ...

Page 260: ...107006 11 EN FR26 GLO 0300 Printed in Germany 52 9 3 Declaration of conformity ...

Page 340: ...Safety Perimeter Guarding Installation Manual FF SPS4 Series Safety Perimeter Guarding ...

Page 536: ...2 107004 15 EN FR26 ROW 0899 Printed in France This page has been left intentionally blank ...

Page 538: ...4 107004 15 EN FR26 ROW 0899 Printed in France This page has been left intentionally blank ...

Page 542: ...107004 15 EN FR26 ROW 0899 Printed in France 8 This page has been left intentionally blank ...

Page 620: ...86 107004 15 EN FR26 ROW 0899 Printed in France This page has been left intentionally blank ...

Page 624: ...90 107004 15 EN FR26 ROW 0899 Printed in France This page has been left intentionally blank ...

Page 626: ...92 107004 15 EN FR26 ROW 0899 Printed in France This page has been left intentionally blank ...

Page 627: ...107004 15 EN FR26 ROW 0899 Printed in France 93 8 CE Declaration of Conformity ...

Page 628: ...94 107004 15 EN FR26 ROW 0899 Printed in France This page has been left intentionally blank ...