GKR/GKL Series

Issue 3

PK 80108

2

Honeywell

•

Sensing and Control

WARNING

IMPROPER INSTALLATION

•

Consult with local safety agencies and their

requirements when designing a machine-control link,

interface and all control elements that affect safety.

•

Strictly adhere to all installation instructions.

Failure to comply with these instructions could

result in death or serious injury.

MOUNT, WIRE, SEAL AND TEST SWITCH

WARNING

IMPROPER OPERATION

•

Ensure key travels to the given minimum insertion

distance to ensure switch contact transfer.

•

Ensure key travels to maximum extraction distance to

ensure correct operation of the positive break

mechanism.

•

Do not exceed 100 N (22.4 lb) actuation force or 1000

N (224 lb) extraction force to actuator key to prevent

switch failure.

•

Do not use the key as a stop for the door.

Failure to comply with these instructions could

result in death or serious injury.

1. Refer to:

•

Page 5 for wiring configurations for both lock types.

•

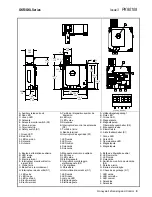

Page 6 for switch mounting dimensions,

specifications.

•

Page 7 for key mounting dimensions.

2. Rotate head (if desired):

•

Rotate the auxiliary release to the unlocked position

(requires cover to be in place).

•

Using the TORX tamper resistant bit (included),

loosen tamper-proof screws and remove head.

•

Rotate head to desired position (90

°

increments),

ensuring seal and plunger remain in correct position

while reassembling head.

•

Torque tamper-proof screws 1,36-1,80 N m

(12-16 in lb).

•

Return auxiliary release to the locked position.

3. Ensure proper clearance for switch and key at

mounting location.

4. Align switch and key together before mounting.

5. Mount switch and key:

•

Torque switch to mounting surface: 4,9-5,9 N m

(43-52 in lb) using M5 or #10 screws.

•

Torque key to mounting surface: 4-2,8 N m

(21-25 in lb) using M5 or #10 screws.

6. Refer to circuit diagram on switch housing. Diagram

depicts safety switch when key is inserted.

7.

Remove tamper-proof screws on cover plate.

8. Connect stranded wire (0,75 mm

2

-2,5 mm

2

, 18-14

AWG) or solid wire (0,75 mm

2

to 1,5 mm

2

, 18-16

AWG) to connector terminals (use 90

°

C wire when

ambient temperature is over 75

°

C):

•

Torque connector to secure cable to switch

enclosure (if required): 1,8-2,2 N m (16-19 in lb).

•

Torque switch terminal screws: 0,8-1,0 N m

(7-9 in lb) M3.

•

Torque ground screw: 0,8-1,0 N-m (7-9 in lb) M3.

9. Seal conduit opening according to instructions in PK

80112.

10. Reassemble cover plate.

11. Plug unused conduit entry (plug included). Seal with

Teflon tape or pipe sealant.

12. Plug unused key entry window with snap fit cover

(included).

13. Perform functional tests:

•

Open and close protective guard several times to

ensure key slides easily into switch head.

•

Close protective guard and ensure switch locks. It

must not be possible to open protective guard when

hazardous motion is present.

•

After the switch unlocks, open protective guard.

The hazardous motion must not start when

protective guard is unlocked or open.

14. Apply a strip of paint or wax over the auxiliary release

knob and the switch body cover to detect actuation of

the auxiliary release.

AUXILIARY RELEASE

WARNING

IMPROPER OPERATION

•

Do NOT use the auxiliary release for general

maintenance, repair of the machine, or to start and

stop the machine. Use in an emergency situation only.

Failure to comply with these instructions could

result in death or serious injury

.

CAUTION

PRODUCT DAMAGE

•

Do NOT rotate auxilliary release greater than 90

°

from

either the locked or the unlocked position.

Failure to comply with this instructions may result in

product damage.

Mechanical Lock:

Occurs by internal spring force

when machine protective guard is closed and key is

inserted. Applying voltage to the solenoid unlocks this

version (or by actuating the auxiliary release when power

failure occurs).

Solenoid Lock:

Occurs by applying voltage to the

solenoid after machine protective guard is closed and key

is inserted. Removing the voltage to the solenoid unlocks

protective guard.

The auxiliary release of the switch lock mechanism

allows protective guard to be opened. Refer to drawing

on switch cover plate for proper rotation direction.

Summary of Contents for SYA14 Series

Page 2: ...2 107031 23 EN FR26 GLO 1199 Printed in France This page has been left intentionally blank ...

Page 6: ...6 107031 23 EN FR26 GLO 1199 Printed in France This page has been left intentionally blank ...

Page 26: ...26 107031 23 EN FR26 GLO 1199 Printed in France This page has been left intentionally blank ...

Page 62: ...62 107031 23 EN FR26 GLO 1199 Printed in France This page has been left intentionally blank ...

Page 70: ...70 107031 23 EN FR26 GLO 1199 Printed in France This page has been left intentionally blank ...

Page 76: ...76 107031 23 EN FR26 GLO 1199 Printed in France This page has been left intentionally blank ...

Page 78: ...78 107031 23 EN FR26 GLO 1199 Printed in France This page has been left intentionally blank ...

Page 79: ...107031 23 EN FR26 GLO 1199 Printed in France 79 8 CE Declaration of Conformity ...

Page 80: ...80 107031 23 EN FR26 GLO 1199 Printed in France This page has been left intentionally blank ...

Page 84: ......

Page 158: ......

Page 160: ......

Page 161: ...For application help call 1 800 537 6945 Honeywell MICRO SWITCH Sensing and Control 80 ...

Page 165: ...3 107022 14 EN FR26 GLO 0100 Printed in Germany This page has been left intentionally blank ...

Page 201: ...39 107022 14 EN FR26 GLO 0100 Printed in Germany This page has been left intentionally blank ...

Page 205: ...43 107022 14 EN FR26 GLO 0100 Printed in Germany This page has been left intentionally blank ...

Page 207: ...45 107022 14 EN FR26 GLO 0100 Printed in Germany This page has been left intentionally blank ...

Page 208: ...107022 14 EN FR26 GLO 0100 Printed in Germany 46 9 Declaration of Conformity ...

Page 219: ...11 107006 11 EN FR26 GLO 0300 Printed in Germany This page has been left intentionally blank ...

Page 229: ...21 107006 11 EN FR26 GLO 0300 Printed in Germany This page has been left intentionally blank ...

Page 257: ...49 107006 11 EN FR26 GLO 0300 Printed in Germany This page has been left intentionally blank ...

Page 260: ...107006 11 EN FR26 GLO 0300 Printed in Germany 52 9 3 Declaration of conformity ...

Page 340: ...Safety Perimeter Guarding Installation Manual FF SPS4 Series Safety Perimeter Guarding ...

Page 536: ...2 107004 15 EN FR26 ROW 0899 Printed in France This page has been left intentionally blank ...

Page 538: ...4 107004 15 EN FR26 ROW 0899 Printed in France This page has been left intentionally blank ...

Page 542: ...107004 15 EN FR26 ROW 0899 Printed in France 8 This page has been left intentionally blank ...

Page 620: ...86 107004 15 EN FR26 ROW 0899 Printed in France This page has been left intentionally blank ...

Page 624: ...90 107004 15 EN FR26 ROW 0899 Printed in France This page has been left intentionally blank ...

Page 626: ...92 107004 15 EN FR26 ROW 0899 Printed in France This page has been left intentionally blank ...

Page 627: ...107004 15 EN FR26 ROW 0899 Printed in France 93 8 CE Declaration of Conformity ...

Page 628: ...94 107004 15 EN FR26 ROW 0899 Printed in France This page has been left intentionally blank ...