GK Solenoid Safety Interlock Switch

ISSUE 2

PK 81591

For application help: call 1-800-537-6945

Honeywell

•

MICRO SWITCH Sensing and Control 7

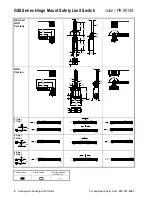

AUXILIARY RELEASE DESCRIPTION (Figure 5)

IMPROPER OPERATION

Do NOT use the auxiliary release for general

maintenance, repair of the machine, or to start and

stop the machine. Use in an emergency situation

only.

Failure to comply with these instructions

could result in death or serious injury.

The auxiliary (or manual) release of the switch

lock mechanism allows the protective guard to be

opened. The auxiliary release is to be used in an

emergency situation only, such as a power failure

when the mechanical lock version is used.

•

Using a screwdriver, rotate the slotted screw as

follows for the listed switch versions to release:

−

Clockwise for Head on Left, Mechanical Lock;

Head on Right, Solenoid Lock.

−

Counterclockwise for Head on Left, Solenoid

Lock; Head on Right, Mechanical Lock.

LOCKING TYPES DESCRIPTION

Mechanical Lock: Occurs by internal spring

force when the protective guard is closed and the

key is inserted. Applying voltage to the solenoid

unlocks this version (or by actuating the auxiliary

release when power failure occurs).

IMPROPER INSTALLATION

Ensure that unintentional power failure on

solenoid lock versions does not cause an unsafe

condition.

Failure to comply with these instructions

could result in death or serious injury.

Solenoid Lock: Occurs by applying voltage to

the solenoid after the protective guard is closed and

the key is inserted. Removing the voltage to the

solenoid unlocks the protective guard.

LOCKING STRENGTH FEATURE

IMPROPER OPERATION

Do not exert over 1000 N (224 lb) extraction force

on actuator key.

Failure to comply with these instructions

could result in death or serious injury.

The switch is equipped with a locking mechanism

to prevent damage to the switch operating head.

This mechanism is designed to withstand 1000 N

(224 lb). If force over 1000 N is exerted on the

actuator key, the mechanism will fracture and

indicate an “open door” condition, requiring

replacement of the entire switch.

ELECTRICAL RATING

A300 - AC15

Q300 - DC13

Ue (Volts)

Ie (Amps)

Ue (Volts)

Ie (Amps)

120

240

6

3

24

125

250

2.9

.55

.27

Rated Thermal Current (Ith) = 10 A

ENVIRONMENTAL RATING

Sealing

IP68

NEMA 1, 4, 6, 6P, 12, 13

Temperature Range

Operating

Storage

-25

°

to 40

°

C (-13

°

to 104

°

F)

-40

°

to 120

°

C (-40

°

to 248

°

F)

Shock

50 G per IEC 68-2-27

Vibration

10 G per IEC 68-2-6

SPECIFICATIONS

Solenoid Power

12 W

Solenoid Operating

Voltage

12 VDC: +10%, -20%

24 VDC: +10%, -20%

48 VDC: +10%, -20%

24 VAC: +10%, -15%

120 VAC: +10%, -15%

240 VAC: +10%, -15%

Contact Material

Fine Silver

Housing Material

Zinc Die Cast

Mechanical Life

One Million Operations

Summary of Contents for SYA14 Series

Page 2: ...2 107031 23 EN FR26 GLO 1199 Printed in France This page has been left intentionally blank ...

Page 6: ...6 107031 23 EN FR26 GLO 1199 Printed in France This page has been left intentionally blank ...

Page 26: ...26 107031 23 EN FR26 GLO 1199 Printed in France This page has been left intentionally blank ...

Page 62: ...62 107031 23 EN FR26 GLO 1199 Printed in France This page has been left intentionally blank ...

Page 70: ...70 107031 23 EN FR26 GLO 1199 Printed in France This page has been left intentionally blank ...

Page 76: ...76 107031 23 EN FR26 GLO 1199 Printed in France This page has been left intentionally blank ...

Page 78: ...78 107031 23 EN FR26 GLO 1199 Printed in France This page has been left intentionally blank ...

Page 79: ...107031 23 EN FR26 GLO 1199 Printed in France 79 8 CE Declaration of Conformity ...

Page 80: ...80 107031 23 EN FR26 GLO 1199 Printed in France This page has been left intentionally blank ...

Page 84: ......

Page 158: ......

Page 160: ......

Page 161: ...For application help call 1 800 537 6945 Honeywell MICRO SWITCH Sensing and Control 80 ...

Page 165: ...3 107022 14 EN FR26 GLO 0100 Printed in Germany This page has been left intentionally blank ...

Page 201: ...39 107022 14 EN FR26 GLO 0100 Printed in Germany This page has been left intentionally blank ...

Page 205: ...43 107022 14 EN FR26 GLO 0100 Printed in Germany This page has been left intentionally blank ...

Page 207: ...45 107022 14 EN FR26 GLO 0100 Printed in Germany This page has been left intentionally blank ...

Page 208: ...107022 14 EN FR26 GLO 0100 Printed in Germany 46 9 Declaration of Conformity ...

Page 219: ...11 107006 11 EN FR26 GLO 0300 Printed in Germany This page has been left intentionally blank ...

Page 229: ...21 107006 11 EN FR26 GLO 0300 Printed in Germany This page has been left intentionally blank ...

Page 257: ...49 107006 11 EN FR26 GLO 0300 Printed in Germany This page has been left intentionally blank ...

Page 260: ...107006 11 EN FR26 GLO 0300 Printed in Germany 52 9 3 Declaration of conformity ...

Page 340: ...Safety Perimeter Guarding Installation Manual FF SPS4 Series Safety Perimeter Guarding ...

Page 536: ...2 107004 15 EN FR26 ROW 0899 Printed in France This page has been left intentionally blank ...

Page 538: ...4 107004 15 EN FR26 ROW 0899 Printed in France This page has been left intentionally blank ...

Page 542: ...107004 15 EN FR26 ROW 0899 Printed in France 8 This page has been left intentionally blank ...

Page 620: ...86 107004 15 EN FR26 ROW 0899 Printed in France This page has been left intentionally blank ...

Page 624: ...90 107004 15 EN FR26 ROW 0899 Printed in France This page has been left intentionally blank ...

Page 626: ...92 107004 15 EN FR26 ROW 0899 Printed in France This page has been left intentionally blank ...

Page 627: ...107004 15 EN FR26 ROW 0899 Printed in France 93 8 CE Declaration of Conformity ...

Page 628: ...94 107004 15 EN FR26 ROW 0899 Printed in France This page has been left intentionally blank ...