37

107022-14 EN FR26 GLO 0100 Printed in Germany

If a protective safety equipment (FF-LS safety light curtains or machine safety control equipment monitored by the FF-LS)

failure occurs during self-check or test input, the protective safety equipment is locked in an OFF condition. This OFF

condition cannot be defeated by turning the power supply voltage OFF and ON.

Table 5-4 Troubleshooting Chart

Failure

Possible cause

Inspect and repair

•

Sensing field is clear, but the protective

safety equipment will not release after

actuation of an external reset push

button switch.

•

Green LED indicator is illuminated.

•

Open circuit between output relays

and machine control circuitry.

•

Inspect terminal wiring and, if

necessary, repair wiring.

•

Blown fuse at output relay terminals.

•

Replace fuse.

•

Sensing field is clear, but the protective

safety equipment will not release after

actuation of an external reset push

button switch.

•

Red LED indicator is illuminated.

•

Open circuit between both or one of

the sensing units and the control

unit.

•

Ensure correct terminal polarity

and proper cable connection

between the sensing and control

units.

•

Translucent surface of sensing units

are contaminated.

•

Clean surface.

•

Sensing unit is defective.

•

Replace sensing unit (matched

pair).

•

Faulty reset pushbutton or open

circuit.

•

Replace reset pushbutton or repair

wiring.

•

Sensing field is clear, but the protective

safety equipment will not release after

actuation of an external reset push

button switch.

•

No LED indicator is illuminated.

•

No supply voltage to the control

unit.

•

Inspect terminal wiring and, if

necessary, repair wiring.

•

Blown fuse at supply voltage

terminal.

•

Replace fuse. See fuse

replacement. (5.4.1)

•

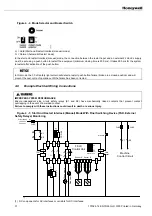

During normal operation the red LED 5,

located near microprocessor on circuit

board in control unit (see figure 5-2),

pulses (illuminates) every 3 seconds.

•

If there is no release when the sensing

field is clear, the red LED 5 may:

•

Illuminate continuously

•

Faulty synchronization

•

Replace control unit.

•

Flicker one time

•

Faulty self test

•

Replace control unit.

•

Flicker two times

•

Faulty communication

•

Replace matched sensor units.

•

Visually inspect cable pair and

replace if required.

•

Flicker three times

•

Faulty communication sensor A

•

Visually inspect sensor cable A

and replace if required.

•

Flicker four times

•

Faulty communication sensor B

•

Visually inspect sensor cable B

and replace if required.

•

Flicker five times

•

Faulty installation parameters

•

Visually inspect compatibility of

sensor and control unit

components. Ensure the beam

number labels on all of the

components are the same.

Summary of Contents for SYA14 Series

Page 2: ...2 107031 23 EN FR26 GLO 1199 Printed in France This page has been left intentionally blank ...

Page 6: ...6 107031 23 EN FR26 GLO 1199 Printed in France This page has been left intentionally blank ...

Page 26: ...26 107031 23 EN FR26 GLO 1199 Printed in France This page has been left intentionally blank ...

Page 62: ...62 107031 23 EN FR26 GLO 1199 Printed in France This page has been left intentionally blank ...

Page 70: ...70 107031 23 EN FR26 GLO 1199 Printed in France This page has been left intentionally blank ...

Page 76: ...76 107031 23 EN FR26 GLO 1199 Printed in France This page has been left intentionally blank ...

Page 78: ...78 107031 23 EN FR26 GLO 1199 Printed in France This page has been left intentionally blank ...

Page 79: ...107031 23 EN FR26 GLO 1199 Printed in France 79 8 CE Declaration of Conformity ...

Page 80: ...80 107031 23 EN FR26 GLO 1199 Printed in France This page has been left intentionally blank ...

Page 84: ......

Page 158: ......

Page 160: ......

Page 161: ...For application help call 1 800 537 6945 Honeywell MICRO SWITCH Sensing and Control 80 ...

Page 165: ...3 107022 14 EN FR26 GLO 0100 Printed in Germany This page has been left intentionally blank ...

Page 201: ...39 107022 14 EN FR26 GLO 0100 Printed in Germany This page has been left intentionally blank ...

Page 205: ...43 107022 14 EN FR26 GLO 0100 Printed in Germany This page has been left intentionally blank ...

Page 207: ...45 107022 14 EN FR26 GLO 0100 Printed in Germany This page has been left intentionally blank ...

Page 208: ...107022 14 EN FR26 GLO 0100 Printed in Germany 46 9 Declaration of Conformity ...

Page 219: ...11 107006 11 EN FR26 GLO 0300 Printed in Germany This page has been left intentionally blank ...

Page 229: ...21 107006 11 EN FR26 GLO 0300 Printed in Germany This page has been left intentionally blank ...

Page 257: ...49 107006 11 EN FR26 GLO 0300 Printed in Germany This page has been left intentionally blank ...

Page 260: ...107006 11 EN FR26 GLO 0300 Printed in Germany 52 9 3 Declaration of conformity ...

Page 340: ...Safety Perimeter Guarding Installation Manual FF SPS4 Series Safety Perimeter Guarding ...

Page 536: ...2 107004 15 EN FR26 ROW 0899 Printed in France This page has been left intentionally blank ...

Page 538: ...4 107004 15 EN FR26 ROW 0899 Printed in France This page has been left intentionally blank ...

Page 542: ...107004 15 EN FR26 ROW 0899 Printed in France 8 This page has been left intentionally blank ...

Page 620: ...86 107004 15 EN FR26 ROW 0899 Printed in France This page has been left intentionally blank ...

Page 624: ...90 107004 15 EN FR26 ROW 0899 Printed in France This page has been left intentionally blank ...

Page 626: ...92 107004 15 EN FR26 ROW 0899 Printed in France This page has been left intentionally blank ...

Page 627: ...107004 15 EN FR26 ROW 0899 Printed in France 93 8 CE Declaration of Conformity ...

Page 628: ...94 107004 15 EN FR26 ROW 0899 Printed in France This page has been left intentionally blank ...