Maintained Explosion-proof Cable Pull Limit Switch

PK 81593

For application help: call 1-800-537-6945

Honeywell

•

MICRO SWITCH Sensing and Control 2

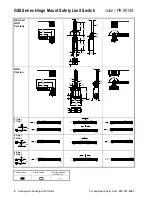

Figure 2: Installation

8 ft.

2,4 m

200 ft. Max.

1

60 m Max.

3

1 ft. Max.

30 cm Max.

Actuating

Cable

SWITCH MOUNTING, WIRING AND SEALING

Step 1 - Ensure you have the following:

•

Switch.

•

(2) 1/4-20 or (2) 5/15-18 screws.

•

#14-#16 AWG stranded or #16-#18 AWG solid

wire.

Step 2 - Mount switch:

SWITCH DAMAGE

Do NOT mount switch upside down or at low point

of conduit runs. Condensation problems may

develop Failure to comply with these instructions

may result in product damage.

•

Mount using (2) 1/4-20 screws from front of

switch, or with (2) 5/15-18 screws from back of

switch. Torque to 43-52 in.-lb (4.9-5.9 N-m).

Step 3 - Wire switch:

•

With a bar or screwdriver in the cover wrenching

lugs, loosen and remove circular cover on front of

switch.

•

Connect stranded or solid wire to switch’s

pressure type connector terminals. (Refer to

circuit diagram on switch housing. Diagram

depicts switch contacts when cable is at proper

tension.) Torque terminal screws and ground

screw to 7-9 in.-lb (0,8-1 N-m).

•

Reassemble cover and tighten securely.

Step 4 - Seal conduit connection: Proper sealing

ensures explosion-proof integrity of the conduit

system.

•

Seal in accordance with National Electrical Code,

paragraphs 500-2 and 501-4.

IMPROPER SYSTEM PERFORMANCE

•

Ensure the attendant circuitry is such that only the

momentary interruption of the control circuit cable

pull contacts is required to open and hold open

the control circuit until such time as both the cable

pull switch and the attendant circuitry are

manually reset.

•

The user is SOLELY RESPONSIBLE for

determining the appropriate level of risk

warranting this type of circuitry.

•

Maintained Cable Pull Limit Switches must be

installed in a fashion that complies with all codes

and standards that are applicable to the particular

application of the device.

•

Failure to comply with these instructions could

result in death or serious injury.

ACTUATING CABLE INSTALLATION

Step 1 - Ensure you have the following (Figure

2):

•

Plastic coated aircraft cable 1/8 in. (3,18 mm) to

3/16 in. (4,76 mm) dia. Use a distinctive color,

such as red, to differentiate actuating cable from

other wires or cables in the area.

•

Thimbles, U-bolt clamps.

•

Cable supports (eyebolts).

Summary of Contents for SYA14 Series

Page 2: ...2 107031 23 EN FR26 GLO 1199 Printed in France This page has been left intentionally blank ...

Page 6: ...6 107031 23 EN FR26 GLO 1199 Printed in France This page has been left intentionally blank ...

Page 26: ...26 107031 23 EN FR26 GLO 1199 Printed in France This page has been left intentionally blank ...

Page 62: ...62 107031 23 EN FR26 GLO 1199 Printed in France This page has been left intentionally blank ...

Page 70: ...70 107031 23 EN FR26 GLO 1199 Printed in France This page has been left intentionally blank ...

Page 76: ...76 107031 23 EN FR26 GLO 1199 Printed in France This page has been left intentionally blank ...

Page 78: ...78 107031 23 EN FR26 GLO 1199 Printed in France This page has been left intentionally blank ...

Page 79: ...107031 23 EN FR26 GLO 1199 Printed in France 79 8 CE Declaration of Conformity ...

Page 80: ...80 107031 23 EN FR26 GLO 1199 Printed in France This page has been left intentionally blank ...

Page 84: ......

Page 158: ......

Page 160: ......

Page 161: ...For application help call 1 800 537 6945 Honeywell MICRO SWITCH Sensing and Control 80 ...

Page 165: ...3 107022 14 EN FR26 GLO 0100 Printed in Germany This page has been left intentionally blank ...

Page 201: ...39 107022 14 EN FR26 GLO 0100 Printed in Germany This page has been left intentionally blank ...

Page 205: ...43 107022 14 EN FR26 GLO 0100 Printed in Germany This page has been left intentionally blank ...

Page 207: ...45 107022 14 EN FR26 GLO 0100 Printed in Germany This page has been left intentionally blank ...

Page 208: ...107022 14 EN FR26 GLO 0100 Printed in Germany 46 9 Declaration of Conformity ...

Page 219: ...11 107006 11 EN FR26 GLO 0300 Printed in Germany This page has been left intentionally blank ...

Page 229: ...21 107006 11 EN FR26 GLO 0300 Printed in Germany This page has been left intentionally blank ...

Page 257: ...49 107006 11 EN FR26 GLO 0300 Printed in Germany This page has been left intentionally blank ...

Page 260: ...107006 11 EN FR26 GLO 0300 Printed in Germany 52 9 3 Declaration of conformity ...

Page 340: ...Safety Perimeter Guarding Installation Manual FF SPS4 Series Safety Perimeter Guarding ...

Page 536: ...2 107004 15 EN FR26 ROW 0899 Printed in France This page has been left intentionally blank ...

Page 538: ...4 107004 15 EN FR26 ROW 0899 Printed in France This page has been left intentionally blank ...

Page 542: ...107004 15 EN FR26 ROW 0899 Printed in France 8 This page has been left intentionally blank ...

Page 620: ...86 107004 15 EN FR26 ROW 0899 Printed in France This page has been left intentionally blank ...

Page 624: ...90 107004 15 EN FR26 ROW 0899 Printed in France This page has been left intentionally blank ...

Page 626: ...92 107004 15 EN FR26 ROW 0899 Printed in France This page has been left intentionally blank ...

Page 627: ...107004 15 EN FR26 ROW 0899 Printed in France 93 8 CE Declaration of Conformity ...

Page 628: ...94 107004 15 EN FR26 ROW 0899 Printed in France This page has been left intentionally blank ...