35

107022-14 EN FR26 GLO 0100 Printed in Germany

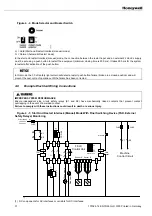

Figure 5-1 Safety Equipment Test Rod Detection

Table 5-1 Summary of Inspection and Test Methods

Inspect and Test

Method

Frequency

Object detection and

machine reaction

•

Insert a 30 mm or 14 mm diameter test rod into

the light curtain sensing field and ensure the

machine stops.

Daily, at each power up, and after each

intervention (or maintenance)

performed on the protective safety

equipment

Operation of the machine

control circuitry

•

Test function generated by the machine (closing

an external normally open contact located in the

“test loop” of the FF-LS control unit)

Each time the machine is used or as

part of each cycle

Output relay

•

Count the machines cycles and evaluate the

number of operations.

1,000,000 operations (1.5 A/220 Vac,

1.5 A / 24 Vdc) or every 3 years if

protective RC elements are mounted

Enclosure

•

Visually inspect enclosure to ensure the control

unit is closed and locked. The key should be

kept by an appointed person.

Based on environment and needs

Electrical wiring

•

Visually inspect the safety light curtain and the

electrical wiring to ensure that they are in

serviceable condition.

Based on environment and needs

Cleaning

•

Use a clean, soft, dry cloth for dust removal.

•

Use a clean, soft cloth with soapy water for

grease removal.

•

Wipe without rubbing (rubbing causes streaks

and static electricity that attracts dust).

•

Products used to clean windows may be used.

•

Never use solvents like petrol, white spirit,

trichlorœthane, trichlorœtylene, or acetone.

Based on environment and needs

5.2

Control Unit Status Indicators

POWER APPLIED TO MACHINE CONTROL SYSTEM

Before intervention, turn off and disconnect power from FF-LS Series safety light curtain and machine.

Failure to comply with these instructions could result in death or serious injury.

The control unit has seven status indicator LEDs (see below). The green status LEDs 1, 2 and 3 are always illuminated if

the supply voltage is present. The yellow status LEDs 4 and 6, the red status LEDs 5 and 7 and a buzzer (acoustic signal)

are used to determine the operational status of the safety equipment. This buzzer (acoustic signal) can be switched on or off

using the buzzer switch located on the control unit printed circuit board (see figure 5-2).

ø 14 mm or ø 30 mm test rod

Summary of Contents for SYA14 Series

Page 2: ...2 107031 23 EN FR26 GLO 1199 Printed in France This page has been left intentionally blank ...

Page 6: ...6 107031 23 EN FR26 GLO 1199 Printed in France This page has been left intentionally blank ...

Page 26: ...26 107031 23 EN FR26 GLO 1199 Printed in France This page has been left intentionally blank ...

Page 62: ...62 107031 23 EN FR26 GLO 1199 Printed in France This page has been left intentionally blank ...

Page 70: ...70 107031 23 EN FR26 GLO 1199 Printed in France This page has been left intentionally blank ...

Page 76: ...76 107031 23 EN FR26 GLO 1199 Printed in France This page has been left intentionally blank ...

Page 78: ...78 107031 23 EN FR26 GLO 1199 Printed in France This page has been left intentionally blank ...

Page 79: ...107031 23 EN FR26 GLO 1199 Printed in France 79 8 CE Declaration of Conformity ...

Page 80: ...80 107031 23 EN FR26 GLO 1199 Printed in France This page has been left intentionally blank ...

Page 84: ......

Page 158: ......

Page 160: ......

Page 161: ...For application help call 1 800 537 6945 Honeywell MICRO SWITCH Sensing and Control 80 ...

Page 165: ...3 107022 14 EN FR26 GLO 0100 Printed in Germany This page has been left intentionally blank ...

Page 201: ...39 107022 14 EN FR26 GLO 0100 Printed in Germany This page has been left intentionally blank ...

Page 205: ...43 107022 14 EN FR26 GLO 0100 Printed in Germany This page has been left intentionally blank ...

Page 207: ...45 107022 14 EN FR26 GLO 0100 Printed in Germany This page has been left intentionally blank ...

Page 208: ...107022 14 EN FR26 GLO 0100 Printed in Germany 46 9 Declaration of Conformity ...

Page 219: ...11 107006 11 EN FR26 GLO 0300 Printed in Germany This page has been left intentionally blank ...

Page 229: ...21 107006 11 EN FR26 GLO 0300 Printed in Germany This page has been left intentionally blank ...

Page 257: ...49 107006 11 EN FR26 GLO 0300 Printed in Germany This page has been left intentionally blank ...

Page 260: ...107006 11 EN FR26 GLO 0300 Printed in Germany 52 9 3 Declaration of conformity ...

Page 340: ...Safety Perimeter Guarding Installation Manual FF SPS4 Series Safety Perimeter Guarding ...

Page 536: ...2 107004 15 EN FR26 ROW 0899 Printed in France This page has been left intentionally blank ...

Page 538: ...4 107004 15 EN FR26 ROW 0899 Printed in France This page has been left intentionally blank ...

Page 542: ...107004 15 EN FR26 ROW 0899 Printed in France 8 This page has been left intentionally blank ...

Page 620: ...86 107004 15 EN FR26 ROW 0899 Printed in France This page has been left intentionally blank ...

Page 624: ...90 107004 15 EN FR26 ROW 0899 Printed in France This page has been left intentionally blank ...

Page 626: ...92 107004 15 EN FR26 ROW 0899 Printed in France This page has been left intentionally blank ...

Page 627: ...107004 15 EN FR26 ROW 0899 Printed in France 93 8 CE Declaration of Conformity ...

Page 628: ...94 107004 15 EN FR26 ROW 0899 Printed in France This page has been left intentionally blank ...