Area

Detection, Control

Cassette Pickup Assembly

Paper Size / Cassette Presence Detection

Multi-Purpose Pickup Assembly

Outline

Paper Presence Detection

Paper Size Detection

Fixing / Registration Assembly

Registration Control

Duplex / Delivery Assembly

Duplex Feed Control

JAM Detection

JAM Detection

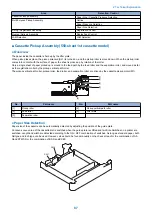

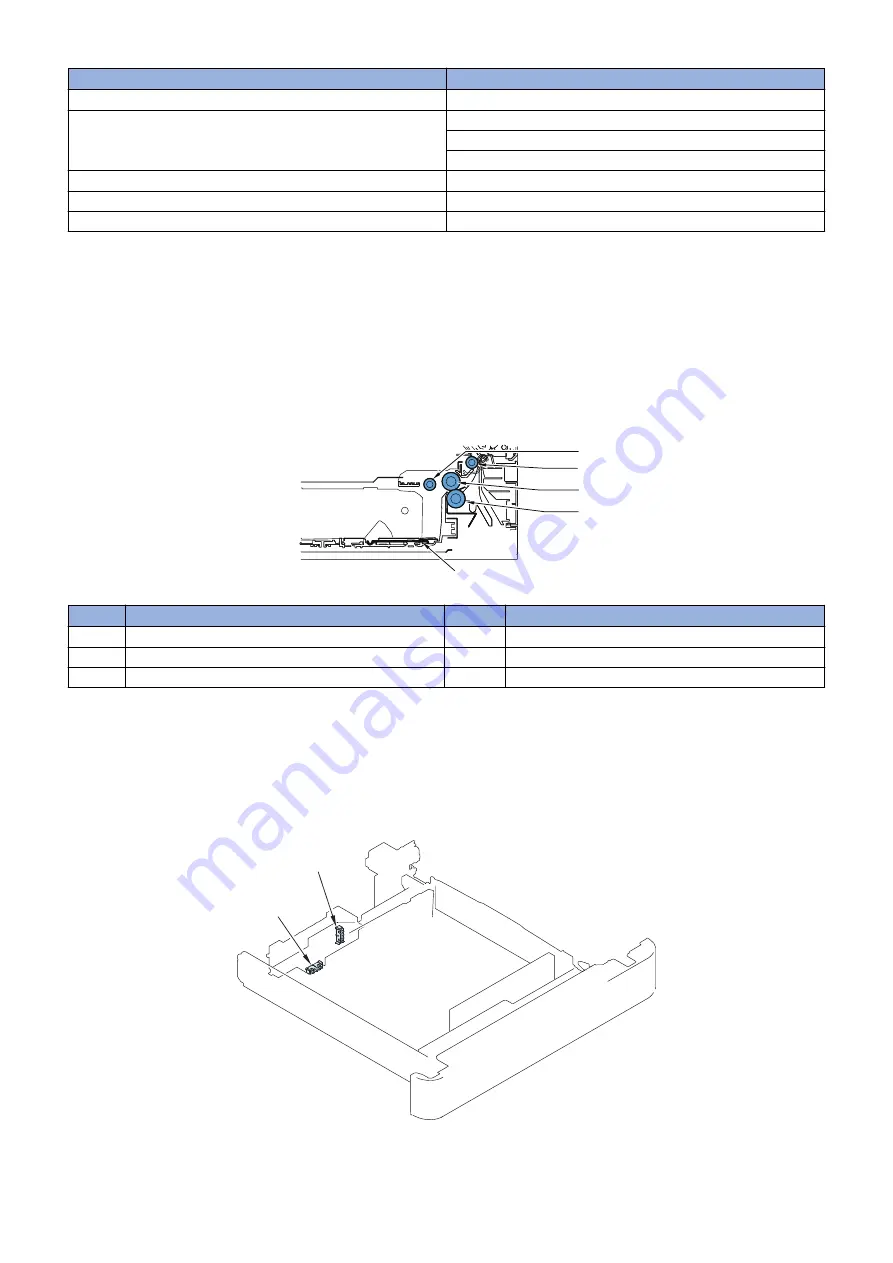

■ Cassette Pickup Assembly (550-sheet 1st cassette model)

● Overview

The paper inside the cassette is held up by the lifter plate.

When pickup takes place, the pickup solenoid (SL1) is turned on, and the pickup roller is moved down. When the pickup roller

comes into contact with the surface of paper, the sheet is picked up by rotation of the roller.

Only a single sheet of paper picked up is moved to the feed path by the feed roller and the separation roller, and moved as far

as the registration roller by the pickup vertical path roller.

The pickup vertical path roller, pickup roller, feed roller, and separation roller are driven by the cassette pickup motor (M1).

[4]

[1]

[2]

[3]

[5]

No.

Part name

No.

Part name

[1]

Pickup roller

[4]

Pickup vertical path roller

[2]

Feed roller

[5]

Lifter plate

[3]

Separation roller

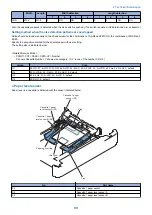

● Paper Size Detection

Paper size of the cassette can be automatically detected by adjusting the position of the guide plate.

Concavo-convex area of the cassette dial is switched when the guide plate is shifted and two Size Switches on a printer are

switched. Length and width are detected according to the ON / OFF combination of switches. As long as standard paper, both

AB type and inch type can be used. However, size should be found manually on the check screen for the combination of A5-

Rand STMT-R or the combination of B5-R and EXEC.

SW6

SW7

2. Technical Explanation

87

Summary of Contents for imageRUNNER 2525 Series

Page 1: ...Revision 9 0 imageRUNNER 2530 2525 2520 Series Service Manual ...

Page 62: ...No Part name 3 Laser unit 2 Technical Explanation 52 ...

Page 119: ...Periodical Service 3 Consumable Parts and Cleaning Parts 110 Cleaning Parts 115 ...

Page 125: ...Cleaning Parts Fixing guide Transfer guide 3 Periodical Service 115 ...

Page 136: ...List of Sensors S18 S17 S16 TS2 HU1 S9 S8 S19 TS1 S11 S12 4 Disassembly Assembly 126 ...

Page 165: ...5 Remove the idler gear 1 claw 1x 4 Disassembly Assembly 155 ...

Page 172: ... 1 4 2 3 2 2 Remove the scanner motor 4 screws 4x 4 Disassembly Assembly 162 ...

Page 186: ...3 Remove the RAM PCB Release the hook 4 Disassembly Assembly 176 ...

Page 187: ...Adjustment 5 Overview 178 Basic Adjustment 180 Adjustment when Replacing the Parts 182 ...

Page 209: ...Error Jam Alarm 7 Outline 200 Error Code 201 Jam Code 213 Alarm Code 219 ...

Page 231: ...Service Mode 8 Overview 222 Details of Service Mode 225 Remote UI Service Mode 302 ...

Page 314: ...Example of report display 8 Service Mode 304 ...

Page 387: ...APPENDICES Service Tools 378 General Circuit Diagram 379 ...