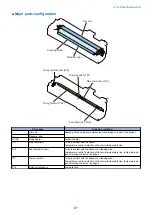

[3]

Density Setting

Main Controller PCB

Photosensitive drum

Developing cylinder

[2]

Environment sensor

[1]

HVT PCB

Developing AC bias

control circuit

DC Controller PCB

Developing DC bias

control circuit

No.

Part name

[1]

Developing bias control signal

[2]

Environment sensor detection signal

[3]

Density setting signal

● Constant voltage control of DC bias and AC bias

The DC bias and AC bias control circuits on the DC controller PCB control the DC bias and AC bias applied to the developing

cylinder to keep their voltage at the fixed level.

● DC bias switch control

The DC bias output varies according to the environment or density setting detected by the environment sensor (HU1).

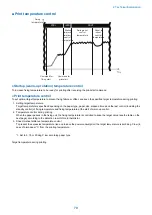

■ Toner Container

● Outline

Toner cartridge is filled with toner and supplies to the drum unit.

Toner cartridge

The toner in the toner cartridge is fed to the sub hopper and then to the developing unit by the toner feed screw. The toner

presence/absence in the sub hopper is detected by the sub hopper toner sensor (TS2) which is a magnetic permeability sensor.

2. Technical Explanation

59

Summary of Contents for imageRUNNER 2525 Series

Page 1: ...Revision 9 0 imageRUNNER 2530 2525 2520 Series Service Manual ...

Page 62: ...No Part name 3 Laser unit 2 Technical Explanation 52 ...

Page 119: ...Periodical Service 3 Consumable Parts and Cleaning Parts 110 Cleaning Parts 115 ...

Page 125: ...Cleaning Parts Fixing guide Transfer guide 3 Periodical Service 115 ...

Page 136: ...List of Sensors S18 S17 S16 TS2 HU1 S9 S8 S19 TS1 S11 S12 4 Disassembly Assembly 126 ...

Page 165: ...5 Remove the idler gear 1 claw 1x 4 Disassembly Assembly 155 ...

Page 172: ... 1 4 2 3 2 2 Remove the scanner motor 4 screws 4x 4 Disassembly Assembly 162 ...

Page 186: ...3 Remove the RAM PCB Release the hook 4 Disassembly Assembly 176 ...

Page 187: ...Adjustment 5 Overview 178 Basic Adjustment 180 Adjustment when Replacing the Parts 182 ...

Page 209: ...Error Jam Alarm 7 Outline 200 Error Code 201 Jam Code 213 Alarm Code 219 ...

Page 231: ...Service Mode 8 Overview 222 Details of Service Mode 225 Remote UI Service Mode 302 ...

Page 314: ...Example of report display 8 Service Mode 304 ...

Page 387: ...APPENDICES Service Tools 378 General Circuit Diagram 379 ...