244

9 MANUFACTURER FUNCTIONS

9.5 Simple cam function

Clutch

Use the clutch when starting or stopping the servo motor by transmitting or shutting commands from the main shaft to the

output axis module side with the clutch on/off.

Set whether or not to use the clutch control with [Cam control data No. 36 - Main shaft clutch control setting].

Although the clutch ON/OFF can be changed during cam control, the setting of [Cam control data No. 36] cannot be changed

from "1 (Clutch command ON/OFF)" to "0 (No clutch)" during cam control.

ON control mode

■

"No clutch"

When [Cam control data No. 36 - Main shaft clutch control setting] is set to "0 (No clutch)", other clutch parameters are not

used due to direct coupled operation.

■

Clutch command ON/OFF

The clutch is turned on/off by turning on/off bit 11 of Control DI2 (2D02h).

(Settings in the OFF control mode are not used in the clutch command ON/OFF mode.)

Clutch smoothing method

Smoothing is processed with the time constant set in [Cam control data No. 43 Main shaft clutch smoothing time constant] at

clutch ON/OFF. Even after clutch ON smoothing is completed, smoothing is processed with the set time constant if the speed

of the input values changes.

The travel distance from turning on to off of the clutch does not change with smoothing.

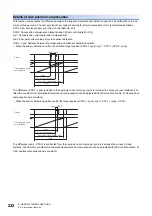

Time constant system exponential curve smoothing

Set [Cam control data No. 42 - Main shaft clutch smoothing system] to "1 (Time constant system (Exponent))".

t

t

Control DI 2 bit 11

Status DO 2 bit 11

Current value before clutch input

Travel distance after clutch output

t

t

63 %

63 %

Speed before clutch processing

Speed after clutch smoothing

Clutch smoothing time constant