9 MANUFACTURER FUNCTIONS

9.5 Simple cam function

231

9

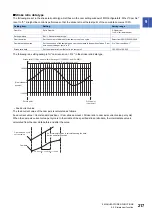

Compensation by touch probe

This system detects registration marks that have been equally printed on the sheet, and compensates the difference between

the actual cam axis one cycle current value and the ideal cam axis one cycle current value (set value of the cam position

compensation target position) by shifting the synchronous phase of the rotary knife axis and the conveyor axis.

■

Setting example: When the ideal detection position of the registration mark is 150 mm and the

distance from the detection position to the cutting position is 50 mm, but the mark is not

detected unless the conveyor feeds the sheet by 151 mm due to expansion of the sheet

By executing compensation, the rotary knife cuts the sheet keeping the distance of 50 mm between the ideal position for

detecting the registration mark and the position for cutting the sheet.

*1 The dot-and-dash line in the figure shows a waveform of when compensation is not executed.

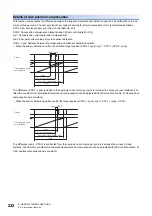

Item

Setting and operation

Cam position compensation target position ([Cam control

data No. 60])

In this example, the ideal detection position of the registration mark is at 150 mm of the cam axis

current value per cycle. Set "150" in the cam position compensation target position.

Cam position compensation time constant ([Cam control

data No. 61])

In this example, the position compensation is executed by one-shot. Set "0" in the cam position

compensation time constant.

360°

180°

0°

151 mm

150 mm

ON

OFF

150 mm

150 mm

151 mm

151 mm

50 mm

201 mm

201 mm

200 mm

200 mm

50 mm

50 mm

*1

Main axis current value

The difference (1 mm) between the registration mark detection position (151 mm) and

the cam position compensation target position (150 mm) is compensated.

Cam axis one cycle

current value

Rotary knife angle

(Cam axis feed current

value)

Conveyor travel distance

(Cam axis input amount)

Sheet

Registration

mark

Cutting position

TPR1 or TPR2

(Cam position compensation

request)