9 MANUFACTURER FUNCTIONS

9.5 Simple cam function

217

9

■

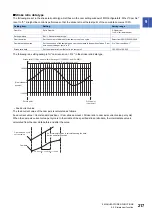

Stroke ratio data type

The following are set in the stroke ratio data type. Set these in the cam setting window of MR Configurator2. When "Cam No."

is set to "0", straight-line control is performed so that the stroke ratio at the last point of the cam data becomes 100%.

The following is a setting example for "cam resolution = 512" in the stroke ratio data type.

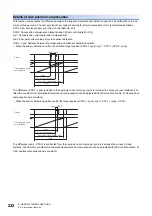

• Feed current value

The feed current value of the cam axis is calculated as follows:

Feed current value = Cam standard po (Cam stroke amount × Stroke ratio to cam axis current value per cycle)

When the cam axis current value per cycle is in the middle of the specified stroke ratio data, the intermediate value is

calculated from the cam data before and after the value.

Setting item

Setting

Setting range

Cam No.

Set a Cam No.

0: Linear cam

1 to 8: User-created cam

Setting method

Set "1: Stroke ratio data type".

Cam resolution

Set the number of divisions for the cam curve of one cycle.

Select from 256/512/1024/2048.

Cam data start position

Set the positions of the cam data and cam control data to the position of when "Cam

axis current value per cycle" is "0".

0 to "Cam resolution - 1"

Stroke ratio data

Set the stroke ratio from the first to the last point.

-100.000 to 100.000

100.000

-100.000

0

Stroke ratio [%] (Can be set within the range of -100.000% and 100.000%)

Cam axis one cycle length [Cam axis cycle unit]

(Cam standard

position)

Zeroth point

512th point

(Last point)

Cam axis one cycle

current value

An intermediate value is calculated using the data

before and after the value.

Cam data

One resolution or between two coordinates