218

9 MANUFACTURER FUNCTIONS

9.5 Simple cam function

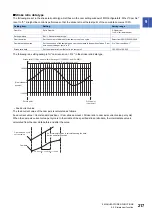

• Cam standard position

The cam standard position is calculated as follows:

Cam standard position = The preceding cam standard po (Cam stroke amount × Stroke ratio at the last point)

For to-and-fro control, create the cam data in which the stroke ratio at the last point is 0%.

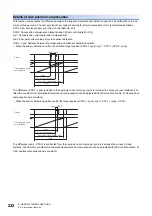

• Cam data start position

This setting is available only for the stroke ratio data type cam data.

The cam data position where the "cam axis current value per cycle" becomes "0" can be set as the cam data start position.

The initial value of the cam data start position is "0". The cam axis is controlled with the cam data from the 0th point (stroke

ratio = 0%).

When a value other than "0" is set as the cam data start position, cam control is started from the point where the stroke ratio is

not 0%.

Set the cam data start position for each cam data within the setting range of "0 to (Cam resolution - 1)".

• Timing of applying cam control data

New values are applied to "Cam No." and "Cam stroke amount" when bit 5 of Control DI2 (2D02h) turns on.

"Cam standard position" is updated when Cam axis current value per cycle passes through the 0th point of the cam data.

t

t

Cam axis one cycle

current value

Cam standard

position

(Third cycle)

Cam standard

position

(Second cycle)

Cam standard

position

(First cycle)

Feed current value

Cam stroke amount × Stroke ratio at the last point

t

t

Cam axis one cycle

current value

Feed current value

Cam standard position

(Does not change because the output value is 0.)

t

t

Cam axis one cycle

current value

Cam standard

position

(Second cycle)

Cam standard

position

(Third cycle)

Feed current value

Cam standard

position

(First cycle)

Cam data

start position

Zeroth point

Last point